Improved microwave variable-frequency power supply assembly and heat dissipation structure

A technology of microwave frequency conversion and frequency conversion power supply, applied in transformer/inductor coil/winding/connection, electrical components, electric solid device and other directions, can solve the problem of low ventilation efficiency, small overall heat dissipation, microwave frequency conversion power supply ventilation and cooling air duct unreasonable issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

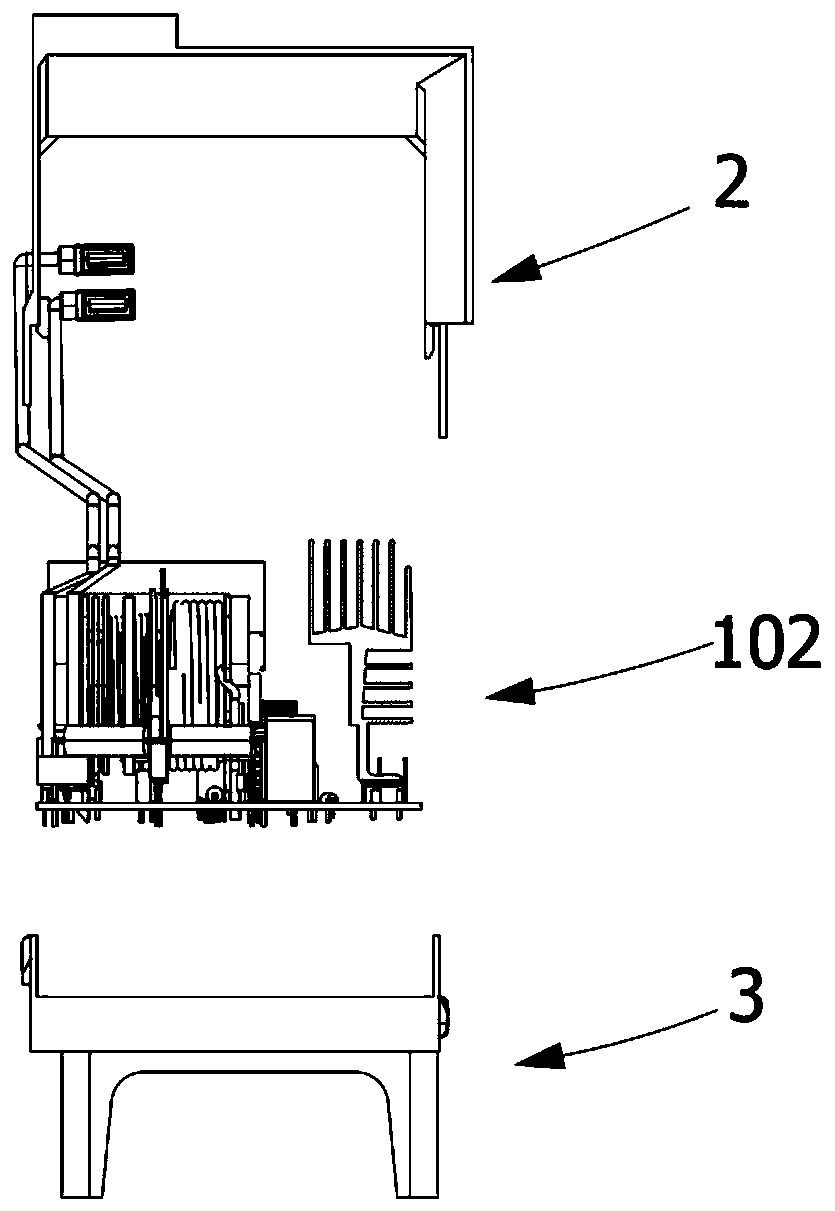

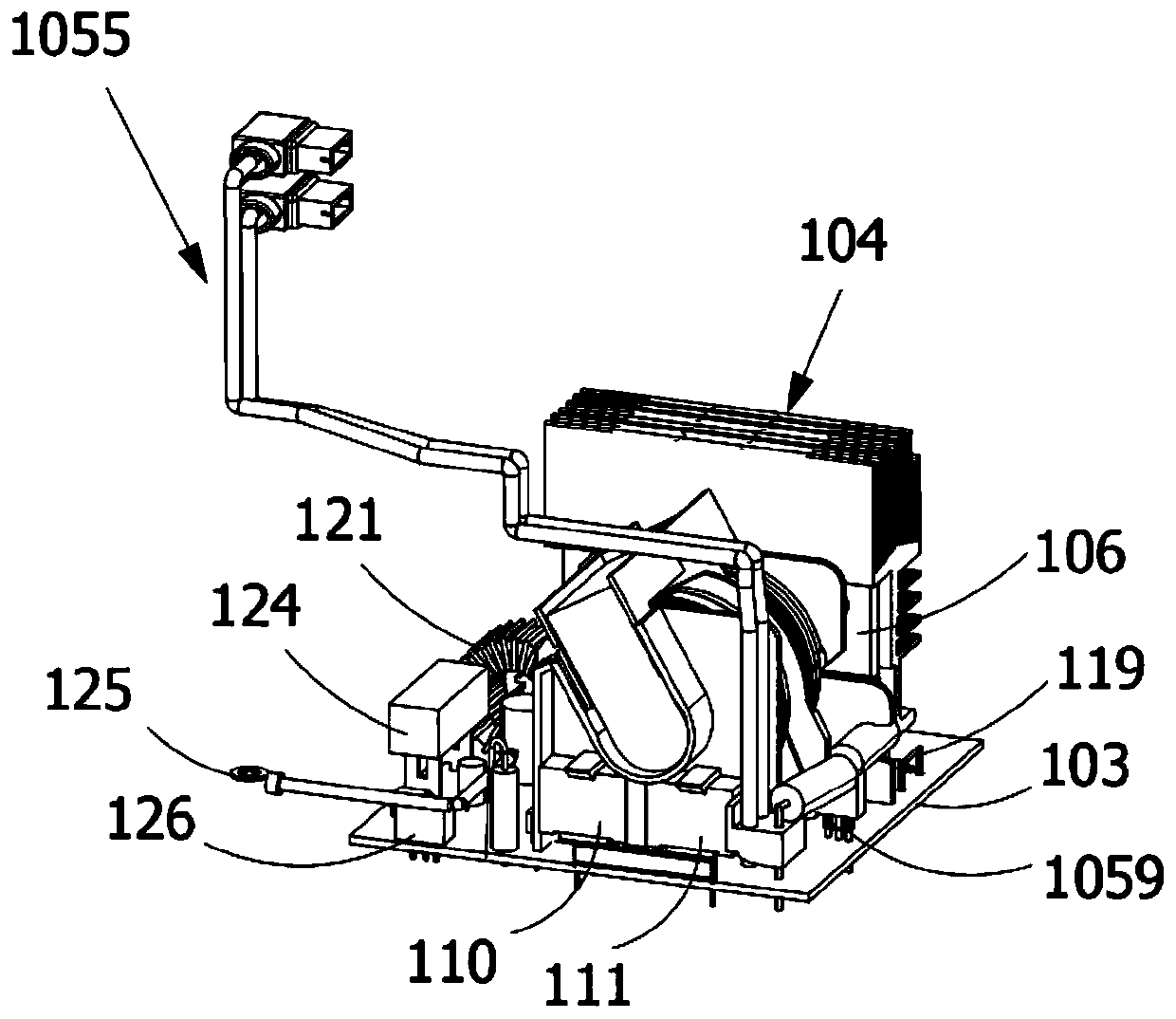

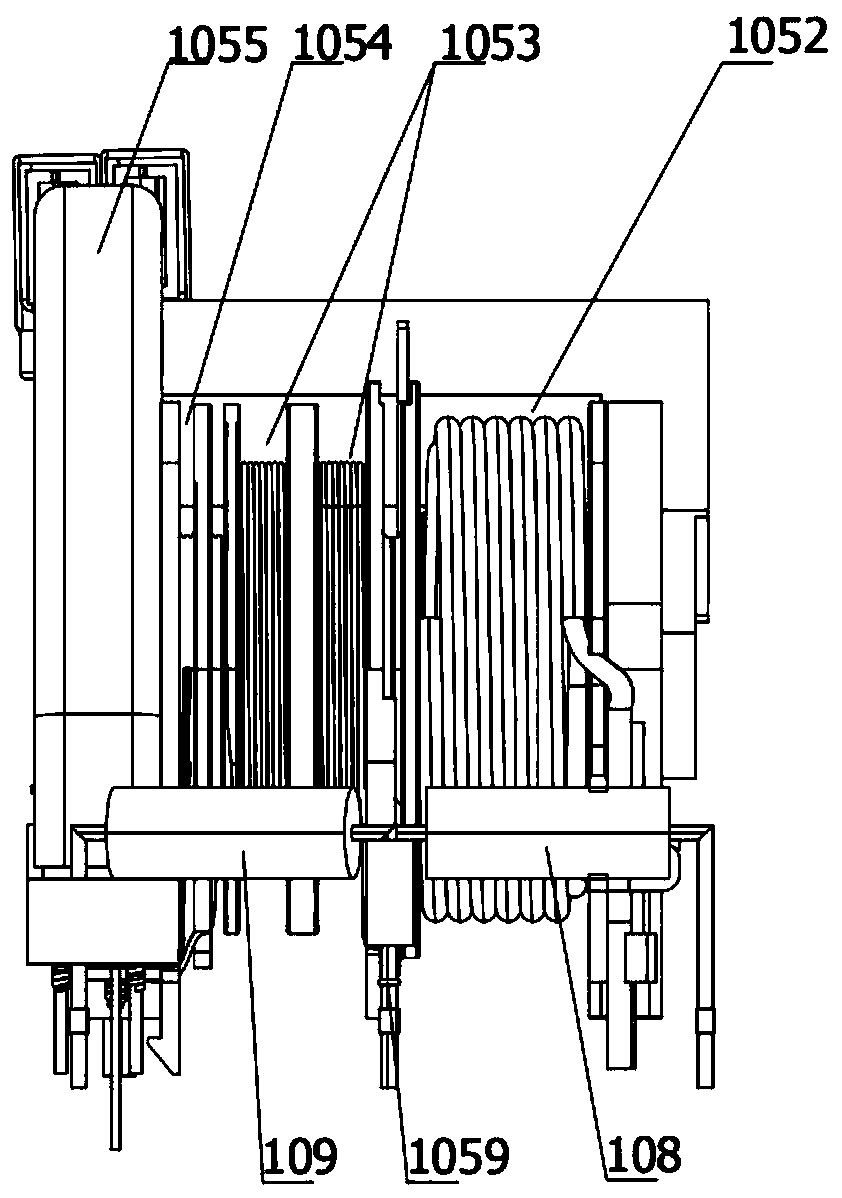

[0055] refer to Figure 1 to Figure 11The improved microwave variable frequency power supply assembly involved in this embodiment 1 includes a housing and a microwave variable frequency power supply board 102 disposed in the inner cavity of the housing, the housing includes an upper cover 2 and a bottom shell 3, and the upper cover 2 and the bottom shell 3 are connected by snap-fitting Integral, forming a sealed air duct in the inner cavity; the variable frequency power supply board 102 includes a printed board 103, a radiator 104, a transformer 105, a first semiconductor component 106, a second semiconductor component 107, a first high voltage diode 108, The second high-voltage diode 109, the first high-voltage capacitor 110 and the second high-voltage capacitor 111; the first semiconductor component 106 and the second semiconductor component 107 are installed on the mounting surface of the radiator 104, and the first high-voltage diode 108, the second high-voltage capacitor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com