Cold Formed Brake Pistons

A piston and piston wall technology, applied in the field of cold forming brake pistons, can solve problems such as limitations, large workload, and inappropriate forming degrees of freedom, and achieve the effect of light and strong structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

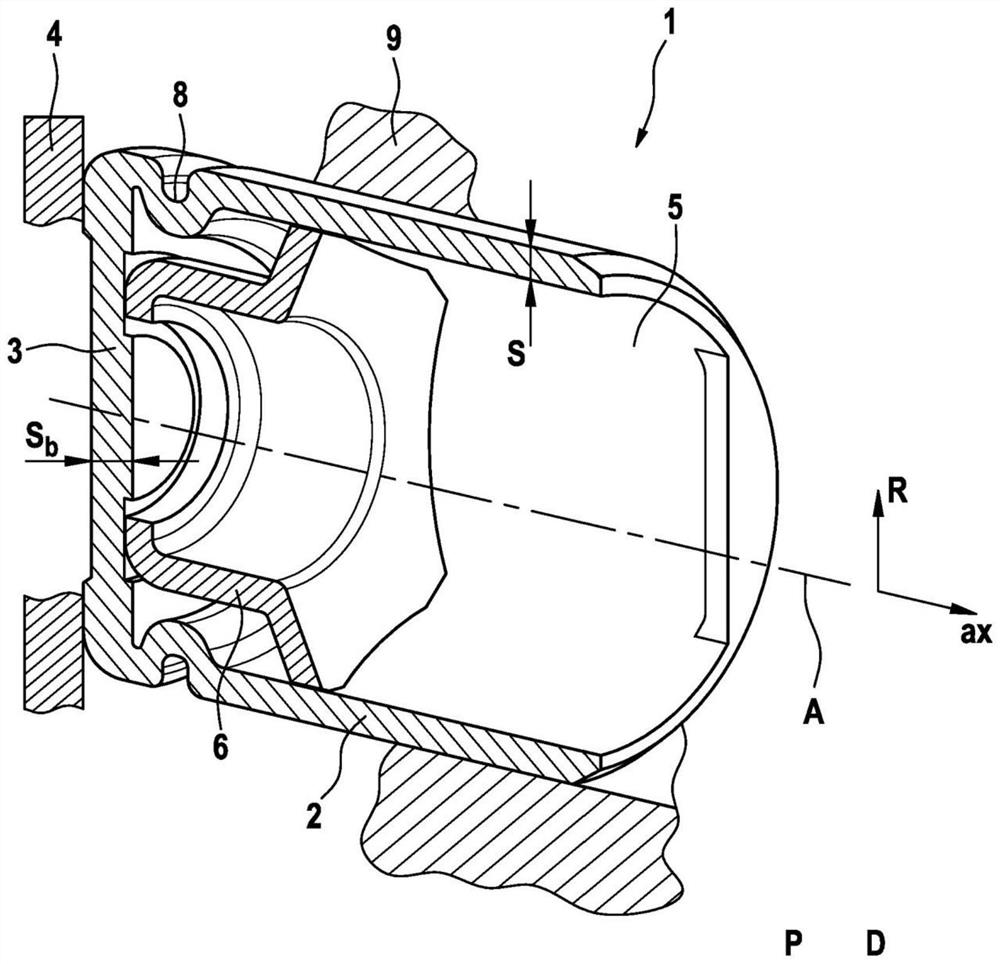

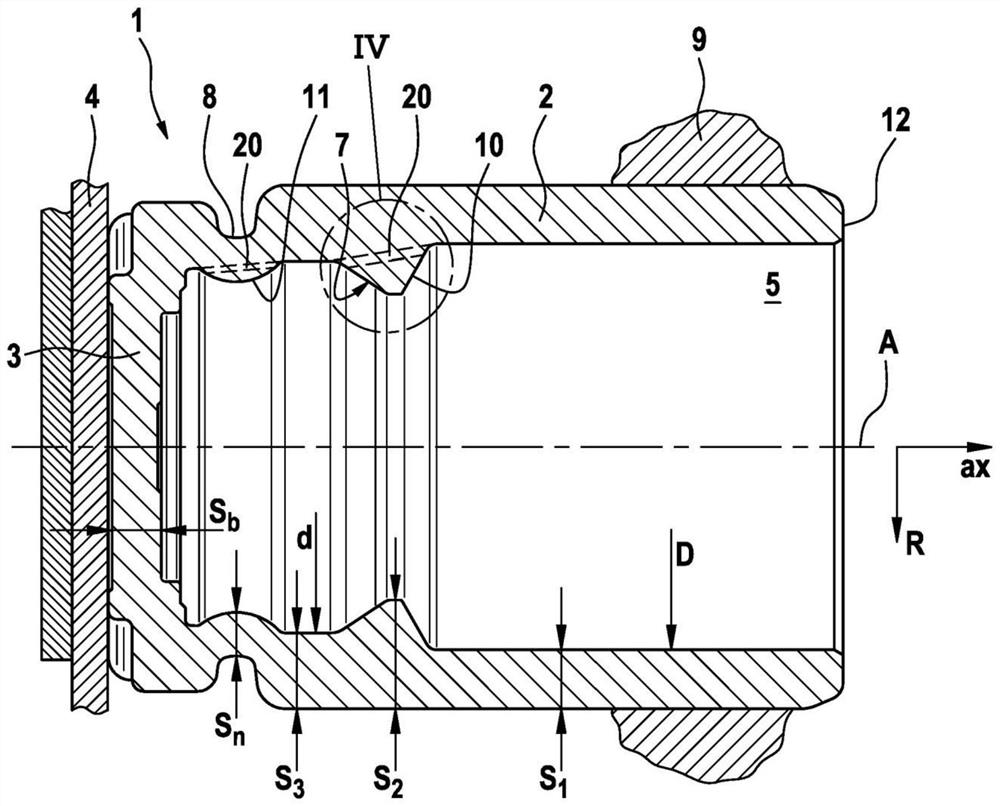

[0020] about figure 1 , in order to simplify understanding and avoid unnecessary complete repetition, the description of EP 2 304 265 B1 is hereby incorporated in its entirety, so that due to this incorporation a basic enumeration of known interrelationships is sufficient.

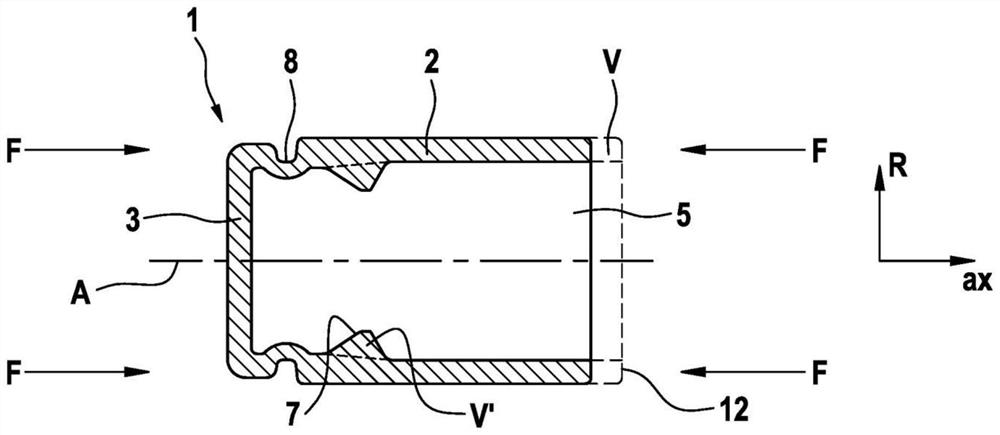

[0021] according to figure 1 The brake piston 1 is made of a metal material (for example a flat metal plate with a wall thickness s0) through a forming process and is constructed in one piece as a cylinder open on one side with a piston longitudinal axis A, a piston wall 2 and a piston head 3 . The piston head 3 serves as an interface in multiple (three) ways. On the one hand, the piston head 3 can be provided with an axial contact surface to bear against the symbolically shown back plate 4 of the brake pad. On the opposite side, the piston head 3 delimits a hydraulic chamber with a piston interior 5 , and the parking brake actuator system likewise acts on the piston head 3 . To this end, the piston in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com