Optical fiber and method for producing same

A manufacturing method and optical fiber technology, applied in the direction of manufacturing tools, clad optical fiber, glass manufacturing equipment, etc., to achieve the effects of improved dispersion characteristics, low bending loss, and low connection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

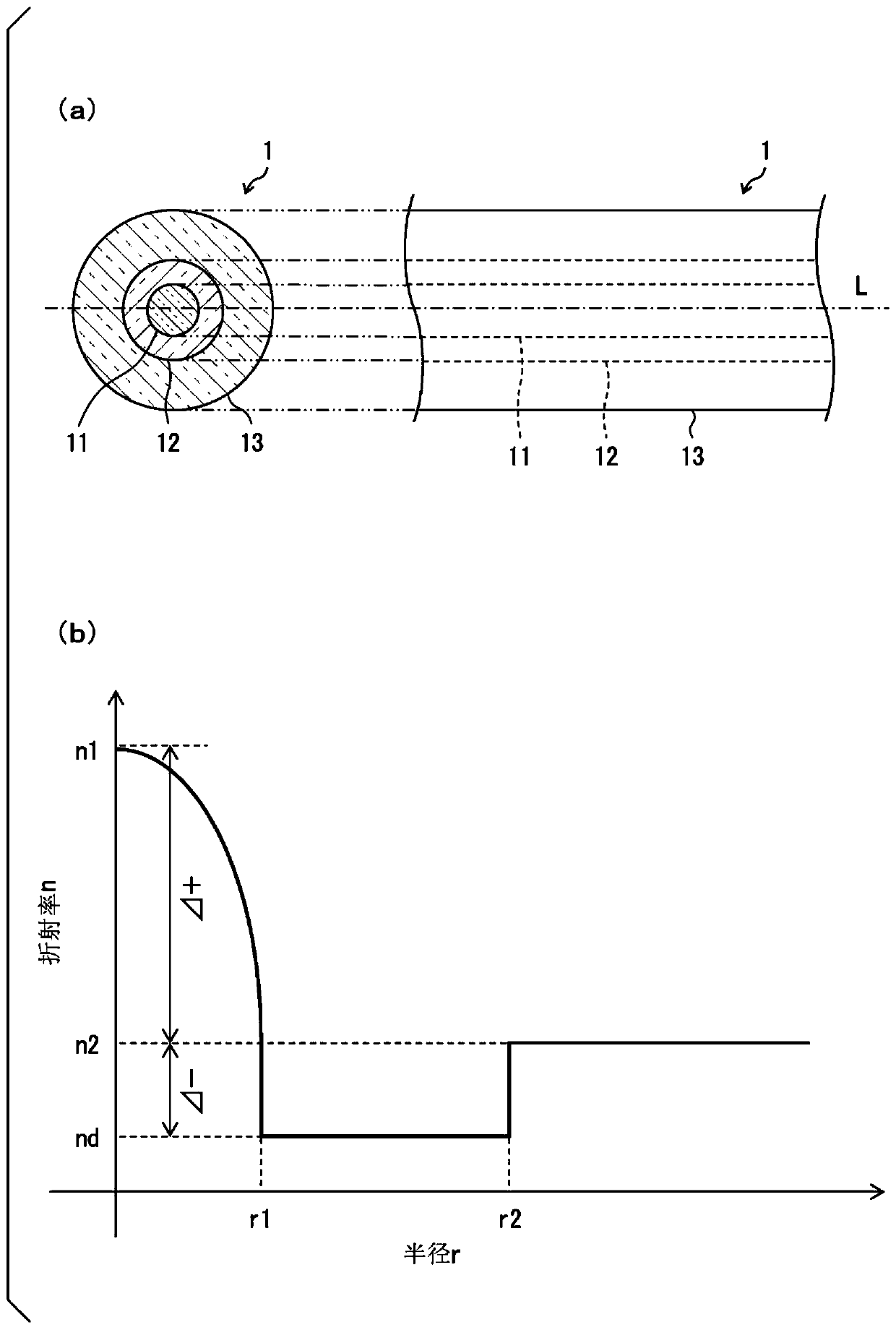

[0031] 〔Structure of optical fiber〕

[0032] refer to figure 1 , the structure of the optical fiber 1 according to the embodiment of the present invention will be described. exist figure 1 Among them, (a) is a sectional view (left) and a side view (right) of the optical fiber 1 , and (b) is a graph showing the refractive index distribution of the optical fiber 1 . figure 1 The cross-sectional structure shown in (a) is the same in each cross-section of the optical fiber 1 perpendicular to the central axis L of the optical fiber 1 .

[0033] The optical fiber 1 is a cylindrical structure mainly composed of quartz glass, such as figure 1 As shown in (a), the core 11 having a circular (radius r1) cross-section, the depressed layer 12 having a cross-section of a ring (inner radius r1, outer radius r2) surrounding the core 11, having The cladding layer 13 is constituted by a cross-section in the shape of a ring (inner radius r2, outer radius r3) surrounding the depressed layer 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com