Dust collector

A technology for vacuum cleaners and suction heads, applied in the direction of vacuum cleaners, suction filters, suction nozzles, etc., can solve the problems of small air suction, high temperature, high cost, etc., and achieve the effects of not easy to wear, long service life, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

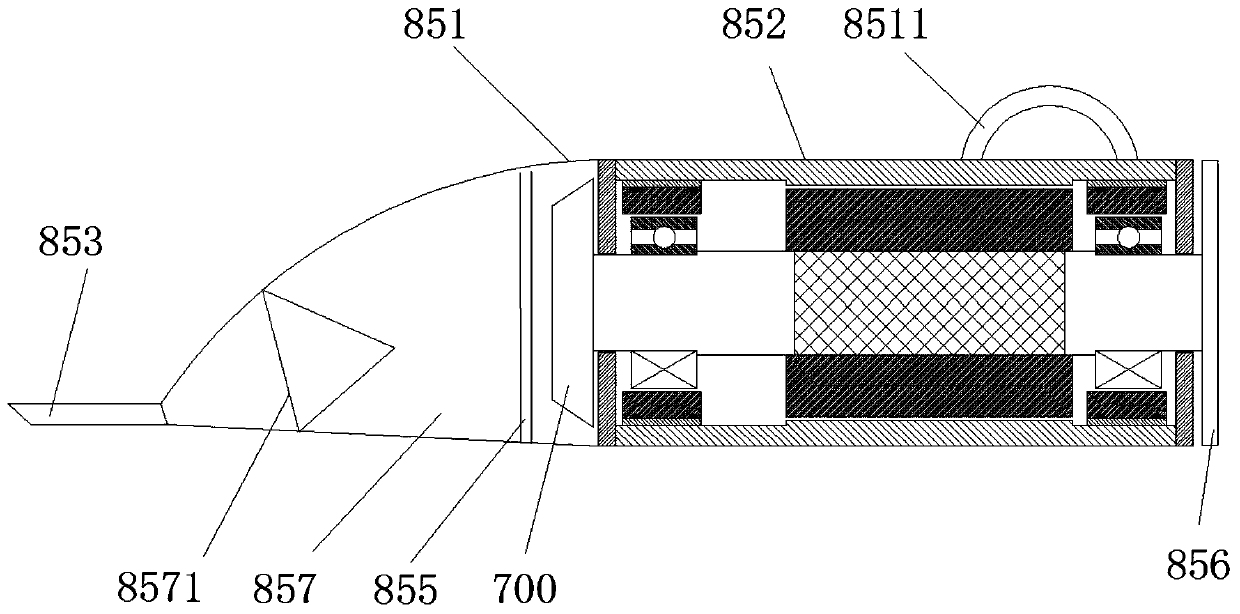

[0054] see figure 1 , a vacuum cleaner using a parallel bearing motor, including a housing 851, a motor 852 and a suction head 853; the two ends of the housing 851 are respectively connected to the motor 852 and the suction head 853, the output end of the motor 852 is connected to the turbine 700, and the filter device 8585 is arranged on the housing Inside 851, the shell 851 is divided into two parts, the part close to the motor 852 accommodates the turbine 700, the part close to the dust suction head 853 is the dust collection chamber 857, the input end of the motor 852 is connected to the circuit board 856, and the circuit board 856 is connected to the power supply for To control the start and stop of the motor 852, a handle 8511 is provided on the housing 851, and a funnel-shaped anti-reflux cover 8571 is arranged in the dust collection chamber 857. Dust falls out from the suction head 853.

Embodiment 2

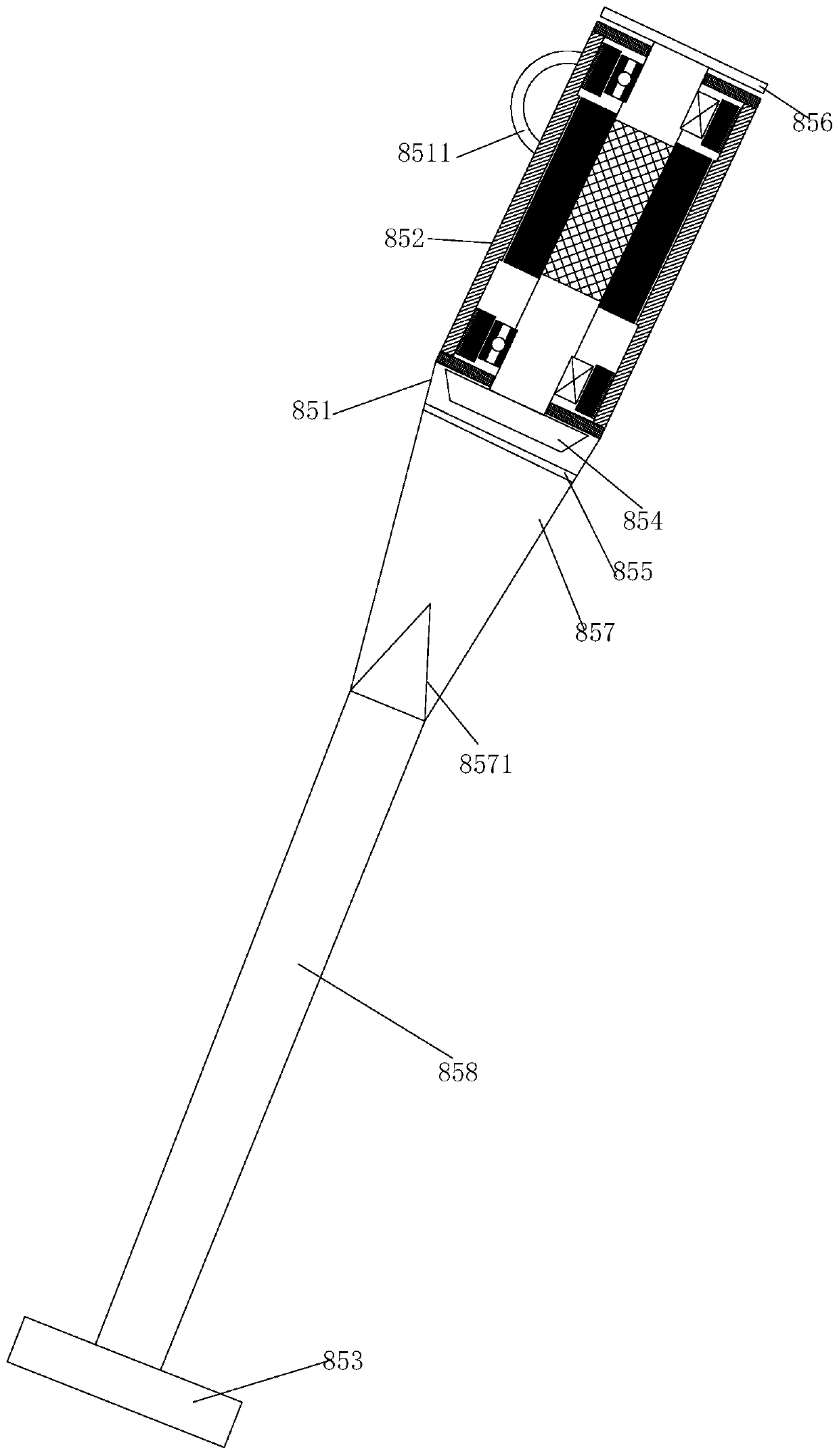

[0056] see figure 2 , this embodiment of the vacuum cleaner is based on the first embodiment of the vacuum cleaner, and a handle 858 is provided between the casing 851 and the dust suction head 853 to extend the length of the vacuum cleaner.

Embodiment 3

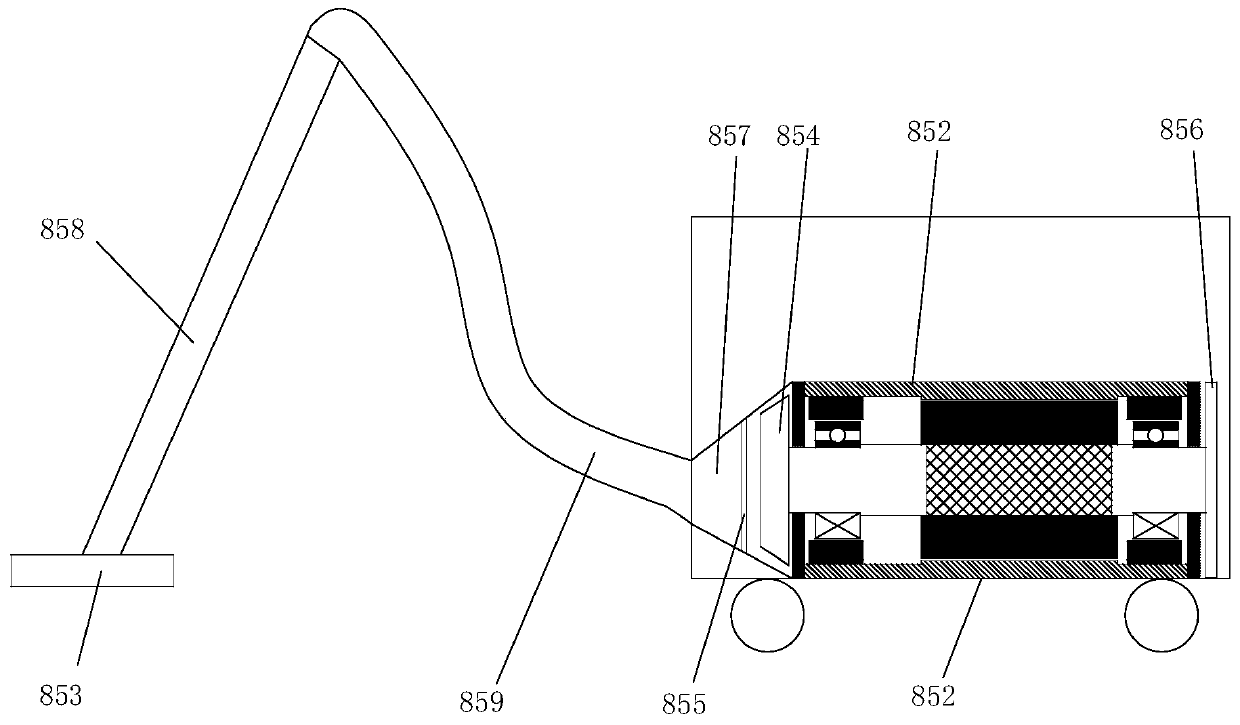

[0058] see image 3 , this embodiment of the vacuum cleaner is based on the second embodiment of the vacuum cleaner, and a hose 859 is provided between the handle 858 and the casing 851 to increase the dust collection range of the dust suction head 853 . In addition, the motor 852 is covered with a box 61 , and the bottom of the box 61 is provided with a roller 62 .

[0059] The dust collection process of the above-mentioned embodiment is: after the power is turned on, the turbine 700 generates a relatively high suction force at a high speed, and under the action of the suction force, the air is discharged at a high speed, and an instantaneous vacuum is generated inside the dust suction head 853, forming a negative pressure difference with the external atmospheric pressure , under the action of this pressure difference, the air containing dust can be sucked. Dust and other sundries enter the dust collection chamber 857 through the dust suction head, and the dust and other sun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com