Multifunctional glaze slip preparation mixer for ceramics

A multifunctional mixer technology, applied in mixers, mixers with rotating stirring devices, shaking/oscillating/vibrating mixers, etc., can solve problems such as heavy workload, failure to meet production requirements, general mixing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

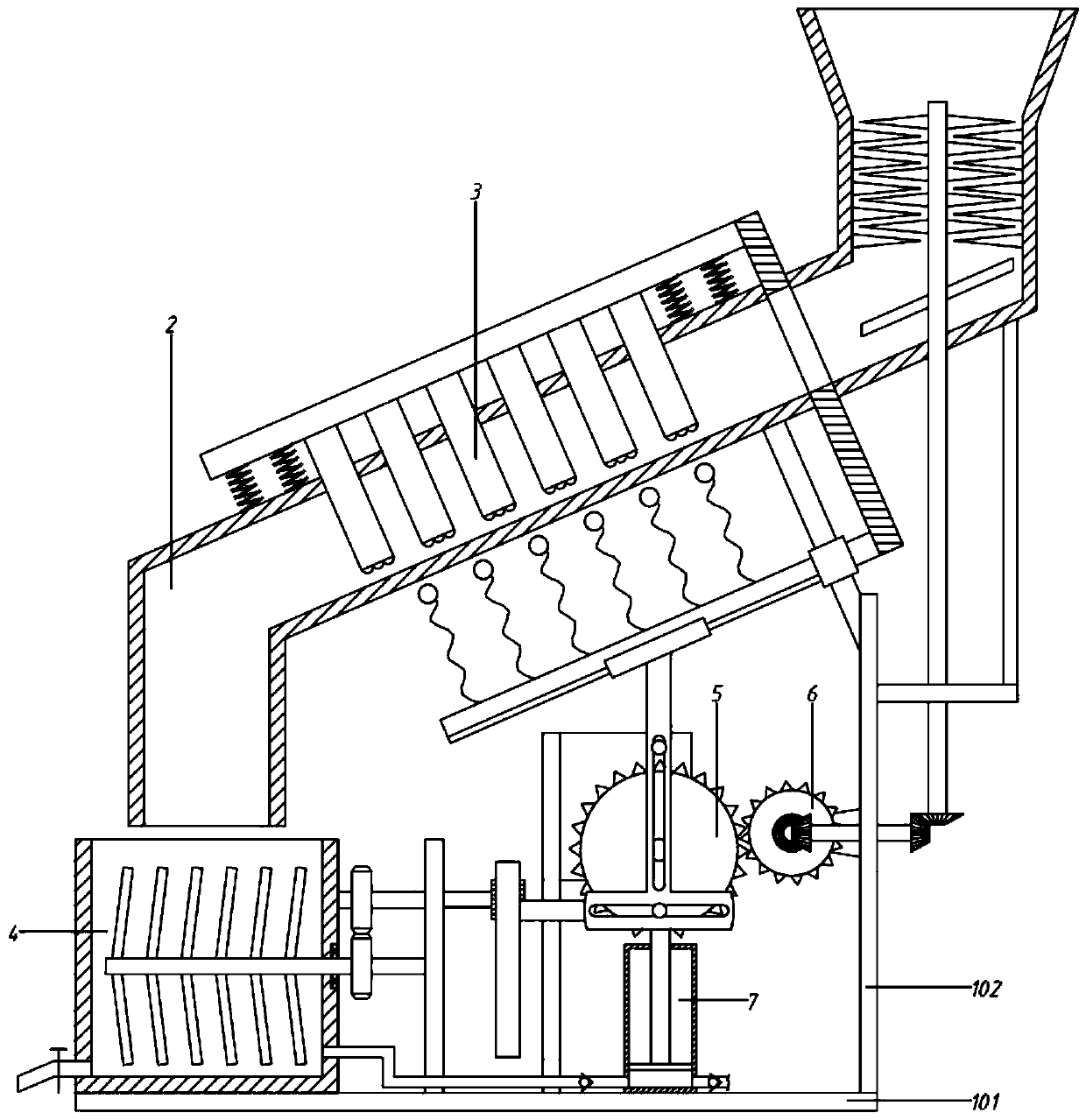

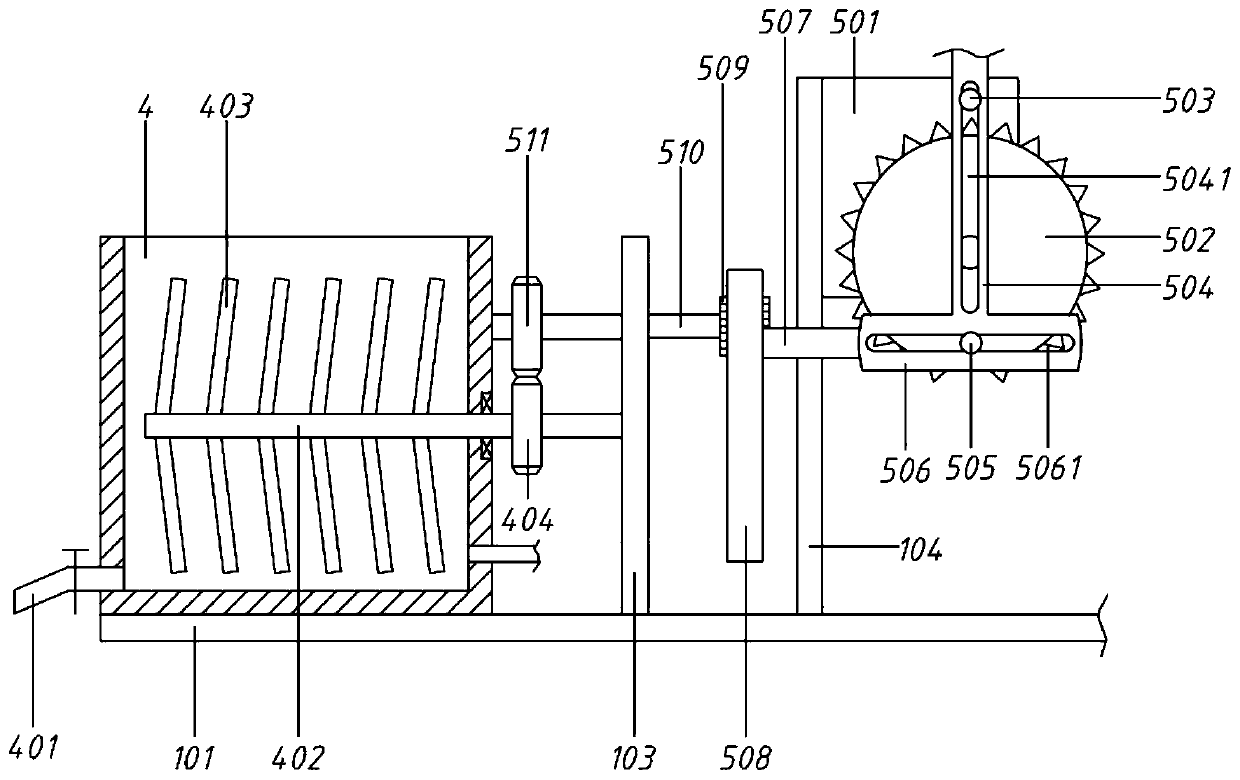

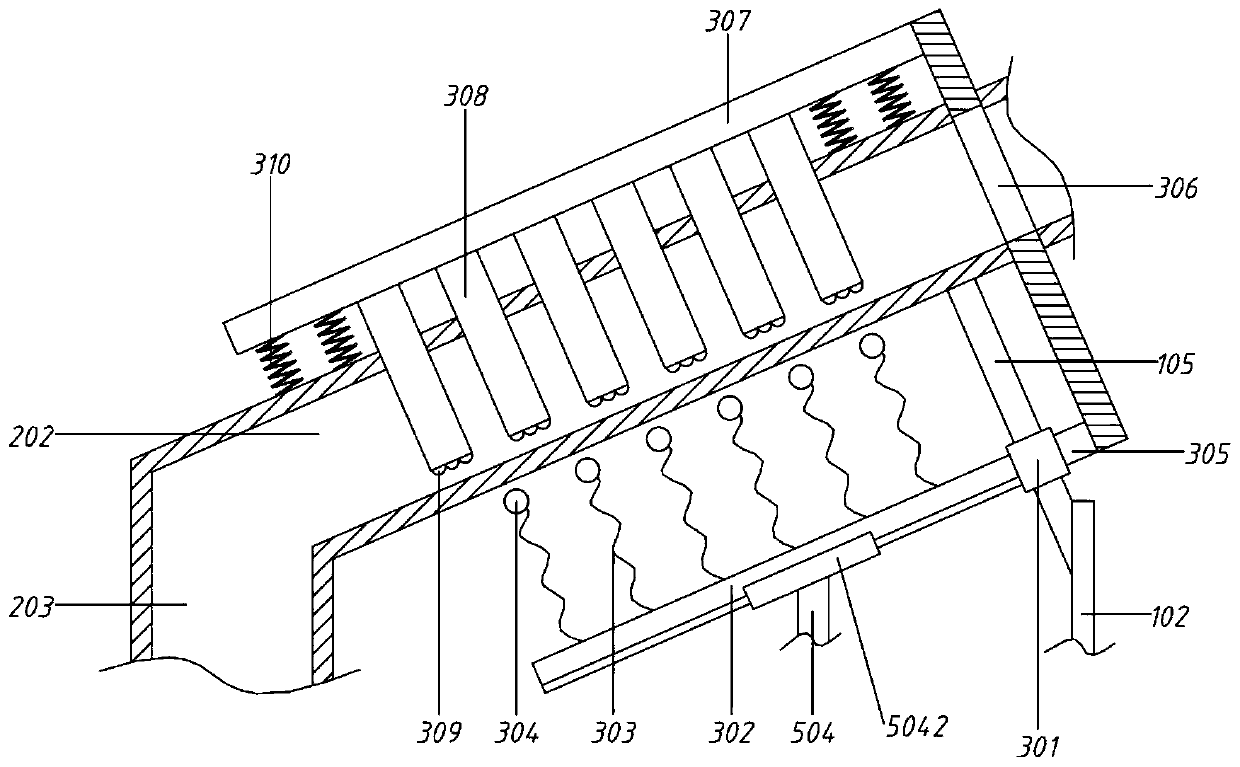

[0050] A multi-functional glaze preparation mixer for ceramics, including a base 101, a mixing box 4, a stirring assembly and a driving assembly 5;

[0051] The mixing box 4 is arranged on the base 101, the top of the mixing box 4 is provided with an opening, the left side of the bottom is connected with a drain pipe 401, and a valve is installed on the drain pipe 401;

[0052] The base 101 is provided with a No. 1 support plate 103 and a No. 2 support plate 104 at intervals corresponding to the right side of the mixing box 4. The No. 1 support plate 103 and the No. 2 support plate 104 are all vertically fixed on the base 101. The No. 1 support plate 103 Located on the left side of No. 2 support plate 104;

[0053] The stirring assembly includes a No. 1 rotating shaft 402 and a type of stirring rod 403; the No. 1 rotating shaft 402 is horizontally arranged, and the right end passes through the right side plate of the mixing box 4 and is rotationally connected with the No. 1 su...

Embodiment 2

[0057] A multi-functional glaze preparation mixer for ceramics, including a base 101, a mixing box 4, a stirring assembly and a driving assembly 5;

[0058] The mixing box 4 is arranged on the base 101, the top of the mixing box 4 is provided with an opening, the left side of the bottom is connected with a drain pipe 401, and a valve is installed on the drain pipe 401;

[0059] The base 101 is provided with a No. 1 support plate 103 and a No. 2 support plate 104 at intervals corresponding to the right side of the mixing box 4. The No. 1 support plate 103 and the No. 2 support plate 104 are all vertically fixed on the base 101. The No. 1 support plate 103 Located on the left side of No. 2 support plate 104;

[0060] The stirring assembly includes a No. 1 rotating shaft 402 and a type of stirring rod 403; the No. 1 rotating shaft 402 is horizontally arranged, and the right end passes through the right side plate of the mixing box 4 and is rotationally connected with the No. 1 su...

Embodiment 3

[0068] A multi-functional glaze preparation mixer for ceramics, including a base 101, a mixing box 4, a stirring assembly and a driving assembly 5;

[0069] The mixing box 4 is arranged on the base 101, the top of the mixing box 4 is provided with an opening, the left side of the bottom is connected with a drain pipe 401, and a valve is installed on the drain pipe 401;

[0070] The base 101 is provided with a No. 1 support plate 103 and a No. 2 support plate 104 at intervals corresponding to the right side of the mixing box 4. The No. 1 support plate 103 and the No. 2 support plate 104 are all vertically fixed on the base 101. The No. 1 support plate 103 Located on the left side of No. 2 support plate 104;

[0071] The stirring assembly includes a No. 1 rotating shaft 402 and a type of stirring rod 403; the No. 1 rotating shaft 402 is horizontally arranged, and the right end passes through the right side plate of the mixing box 4 and is rotationally connected with the No. 1 su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com