Screw conveying treatment system

A technology of screw conveying and screw conveyor, which is applied in the field of screw conveying processing system, can solve problems such as low efficiency and inability to continuously feed materials, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

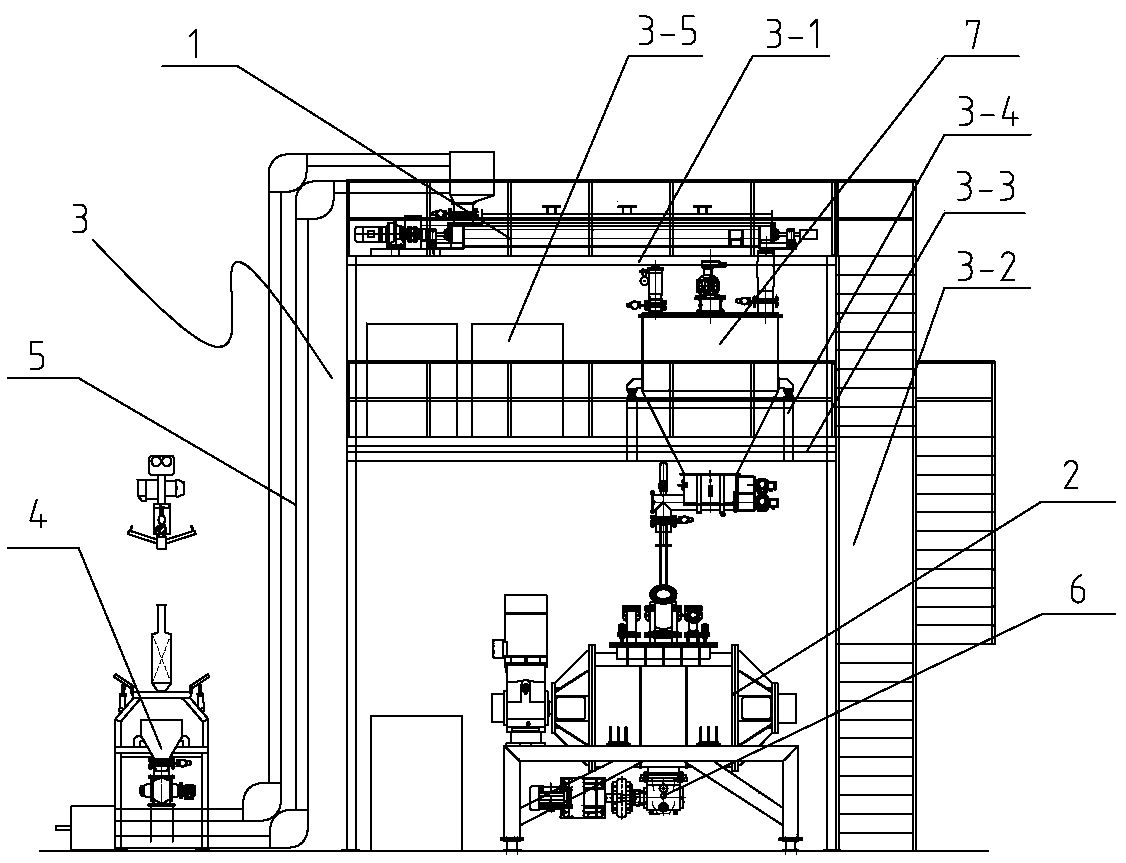

[0010] See figure 1 As shown, a screw conveying system includes a screw conveyor 1 and a mixer 2. The screw conveyor 1 is arranged on the top of the support 3, and one side of the support 3 is provided with an unpacking machine 4. The unpacking machine 4 can be used in the current market. The discharge port of 4 is connected to the feed port of the screw conveyor 1 through the suction pipeline 5, and a metering tank 7 and a mixer 2 are arranged in sequence below the discharge port of the screw conveyor 1, and the discharge port of the metering tank 7 is connected to the mixer 2, the discharge port of the mixer 2 is connected to the discharge pump 6, and the screw conveyor 1 includes a shell and an internal screw. Both the shell and the screw are equipped with a liquid heating channel, and heat transfer oil is generally used for heating. The water in the powder is evaporated to achieve drying, and a water outlet is opened on the top of the shell.

[0011] The support 3 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com