Chuck wrench

A claw and handle technology, applied in the field of multi-purpose manual tool wrench, can solve the problems of easy falling off, affecting work efficiency, uneven force, etc., and achieve the effect of convenient loading and unloading of nuts, improving work efficiency and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

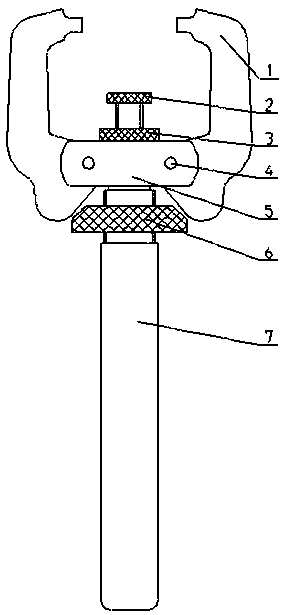

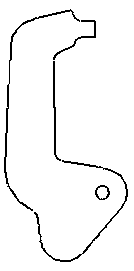

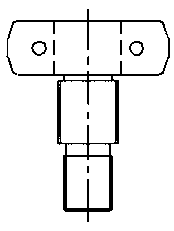

[0015] Such as Figure 1 to Figure 4 As shown: the solution adopted by the present invention to solve its technical problems is: a chuck wrench, characterized in that: the wrench includes: claw 1, adjusting bolt 2, lock nut 3, rivet 4, claw seat 5 , Adjusting nut 6, handle 7, two claws 1, each claw 1 head is provided with a protrusion, the width of the raised hook head is smaller than the groove of the handle nut to be twisted, effective To ensure the gap during work, the corners of the protruding hook are excessively rounded, thereby strengthening the strength of the protruding hook and preventing the occurrence of breakage; there is an arc-shaped protrusion at the tail of the jaw 1, and the arc-shaped protrusion is connected with an inclined surface, and the jaw 1 The tail is also provided with a through hole connecting the claw seat 5 .

[0016] The left and right sides of the claw seat 5 are provided with grooves and two through holes, and the two claws 1 are respectively...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap