Visual servo and manipulator based automatic docking system

A technology of automatic docking and visual servoing, which is applied in the directions of manipulators, program-controlled manipulators, liquid conveying devices, etc., can solve the problems of inability to meet the load of the aircraft docking process, unfavorable continuous operations for refueling operators, and high labor intensity of personnel. The effect of dispatching preparation time, reducing manual information transmission links, and improving docking control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be further explained and described in detail according to the accompanying drawings and specific embodiments.

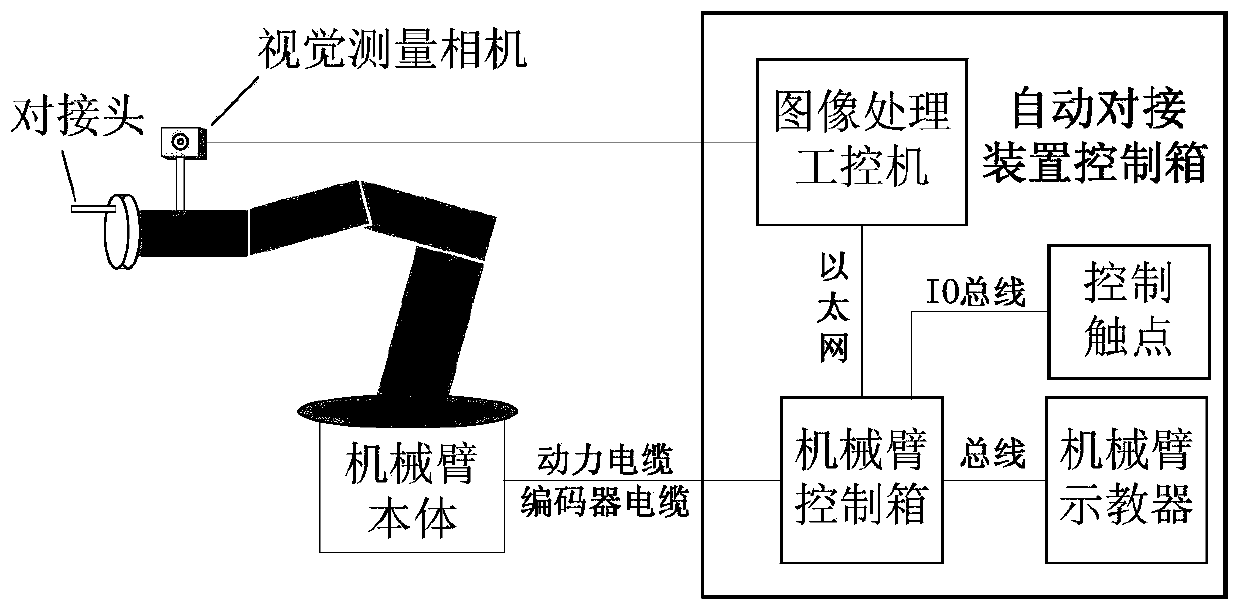

[0036] The robot arm automatic docking system based on visual servo is mainly composed of the robot arm body, the robot arm control box and the teaching pendant, the visual measurement camera and the image processing industrial computer. The basic dynamic docking system is shown in the figure figure 1 , the schematic diagram of the automatic docking system is shown in figure 2 , the block diagram of the automatic docking system is as follows Figure 5 shown.

[0037] The body of the robotic arm is fixedly connected to the joints of the aircraft support equipment, and can change the posture of the joints by adjusting the state of its own joints. The visual measurement camera and the image processing industrial computer capture the aircraft fuselage interface by taking pictures of the aircraft fuselage, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com