Packaging box for aviation integrated bearing and bearing packaging method

A packaging box and bearing technology, which is applied in the direction of packaging under vacuum/special atmosphere, packaging objects under special gas conditions, packaging, etc., can solve the problems of bearing bump damage, poor anti-corrosion and moisture resistance, poor shape matching, etc., and achieve strong buffering effect , easy to open, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

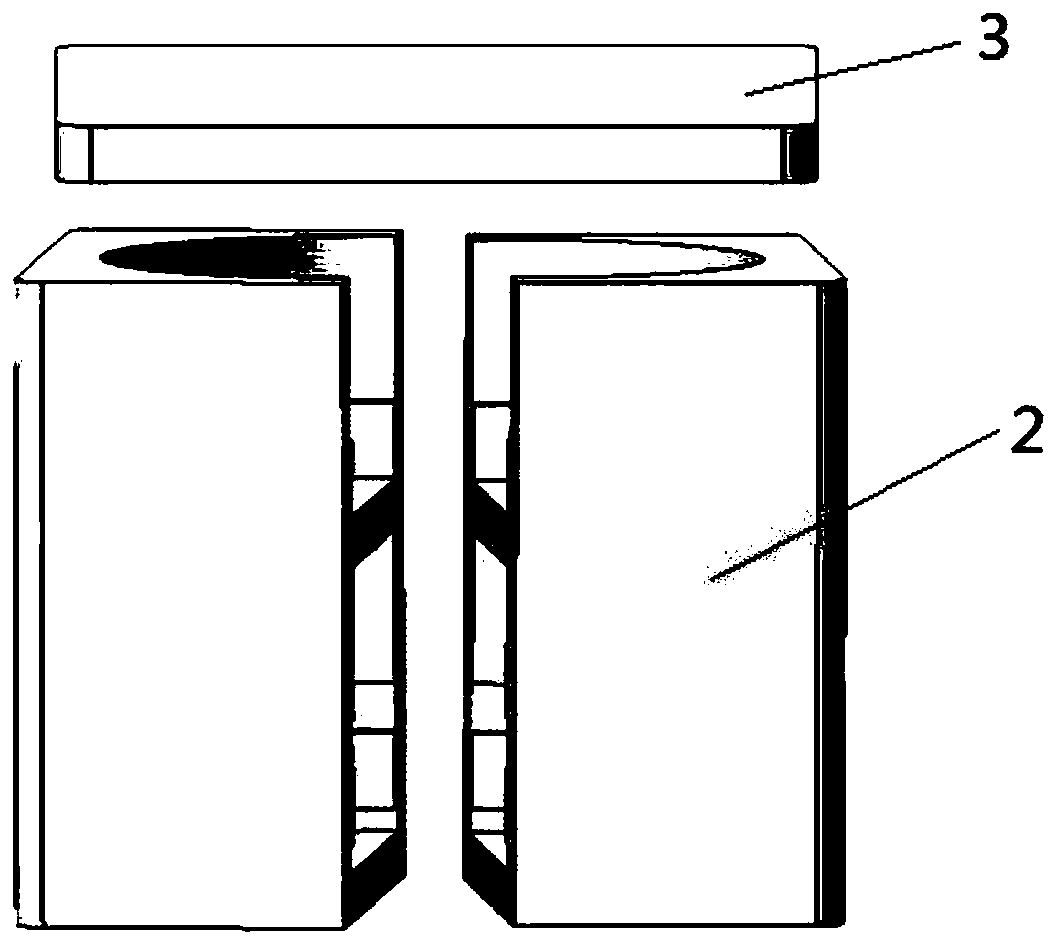

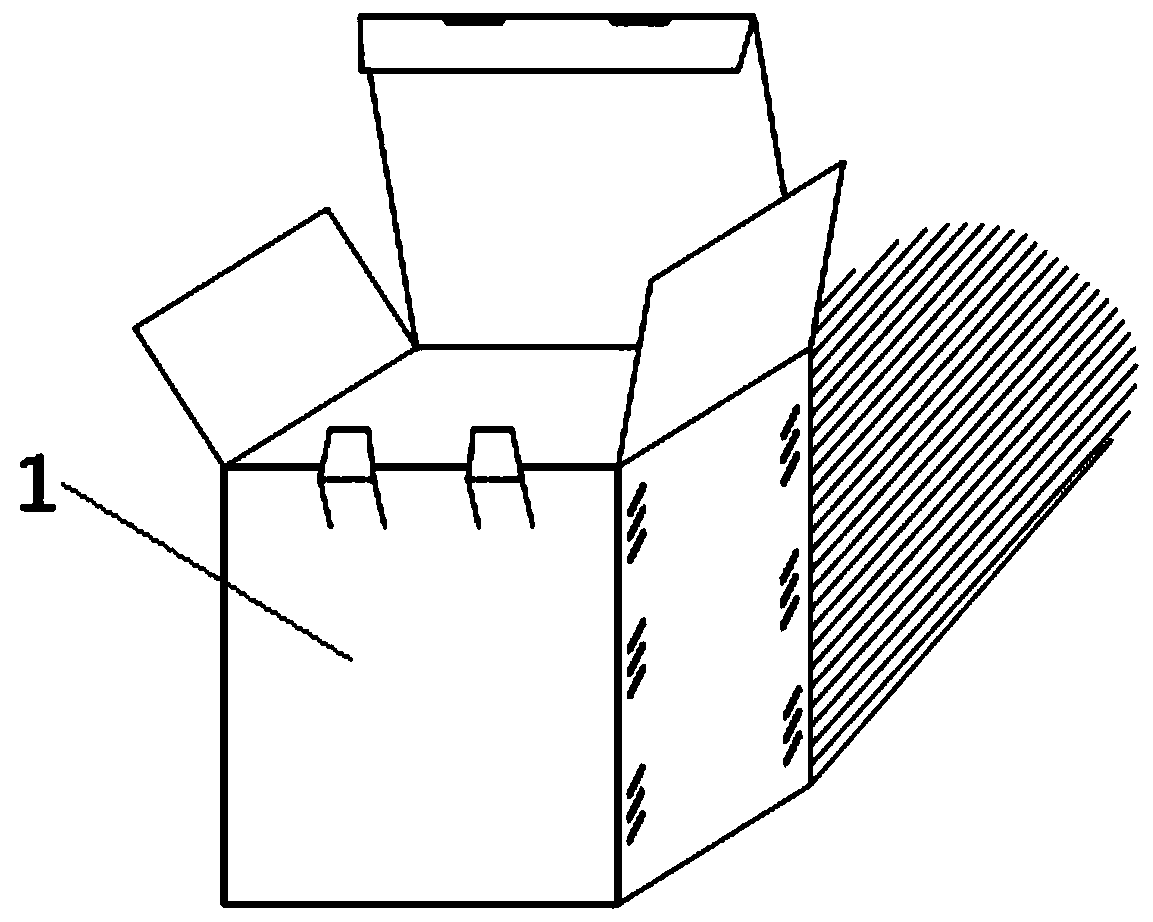

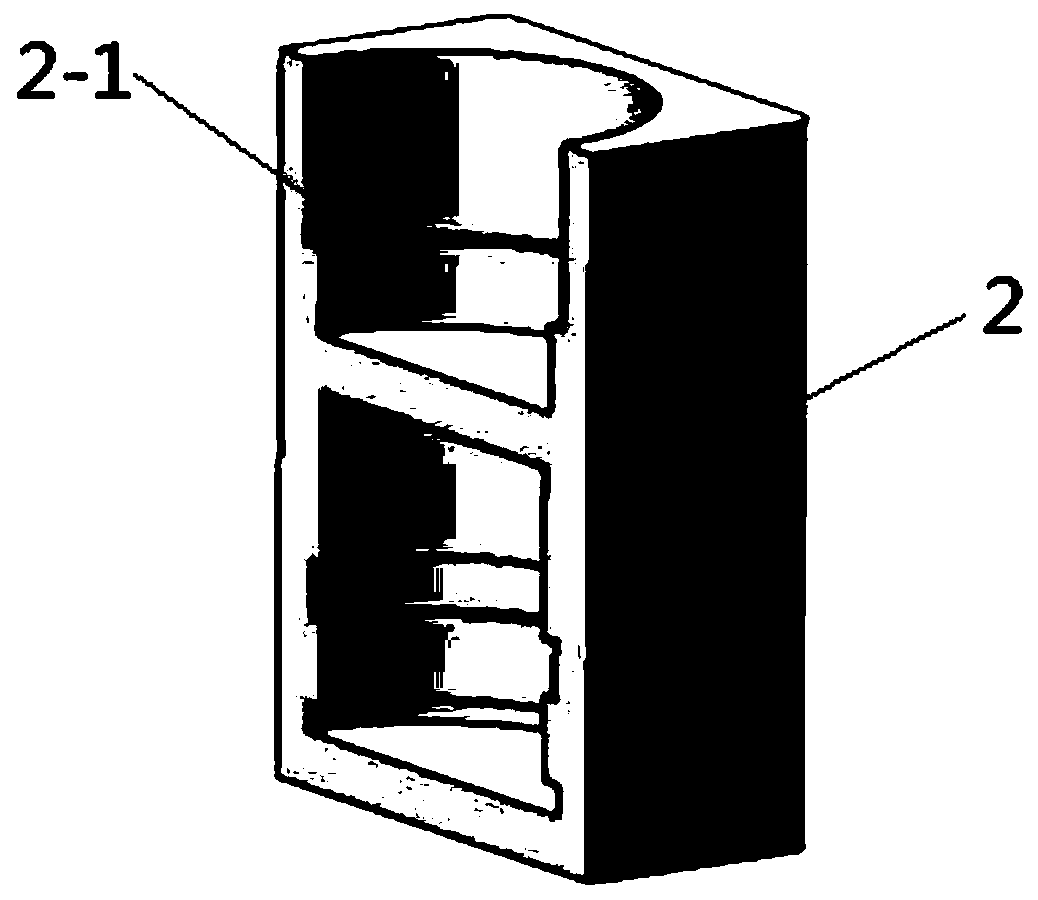

[0024] Specific implementation mode one: combine Figure 1-Figure 3 To illustrate this embodiment, a packaging box for aviation integrated bearings in this embodiment includes an outer packaging box 1 and two symmetrical inner tanks 2;

[0025] The two liners 2 are buckled together to form two upper and lower cavities, the two liners 2 are arranged in the outer packing box 1, and a packaging cover 3 is provided above the upper cavities of the two liners 2,

[0026] The cavities at the bottom of the two liners 2 match the shape of the inner ring 4 of the bearing, and the shape of the upper cavity enables the outer ring 5 and the cage 6 to be embedded in the cavity of the inner liner 2 from top to bottom.

specific Embodiment approach 2

[0027] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the materials of the two inner containers 2 and the packaging cover 3 in this embodiment are both foam plastics.

[0028] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination image 3 To describe this embodiment, the side wall of the upper cavity of this embodiment has a shoulder 2-1.

[0030] Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com