Fluid disinfection device

A technology of disinfection equipment and first fluid, applied in lighting and heating equipment, preparation of alcoholic beverages, cooling/heating devices of lighting devices, etc., can solve equipment loss, high cost, nutrient composition, texture, color and luster Freshness damage and other problems, to achieve the effect of efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

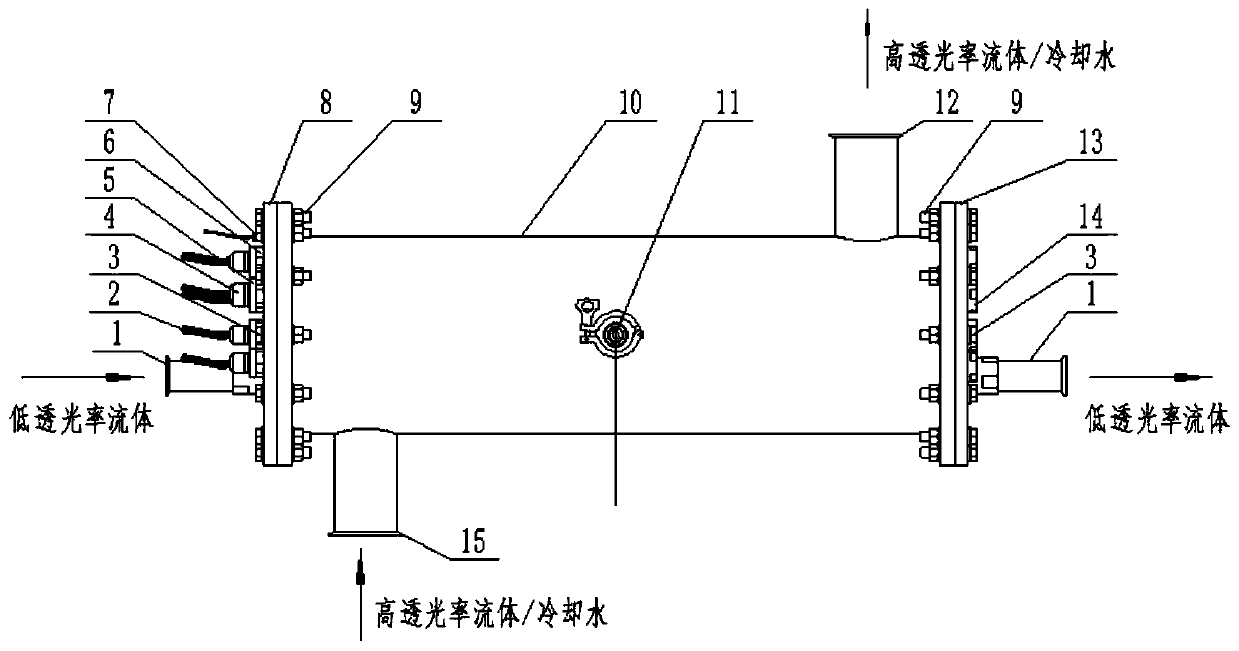

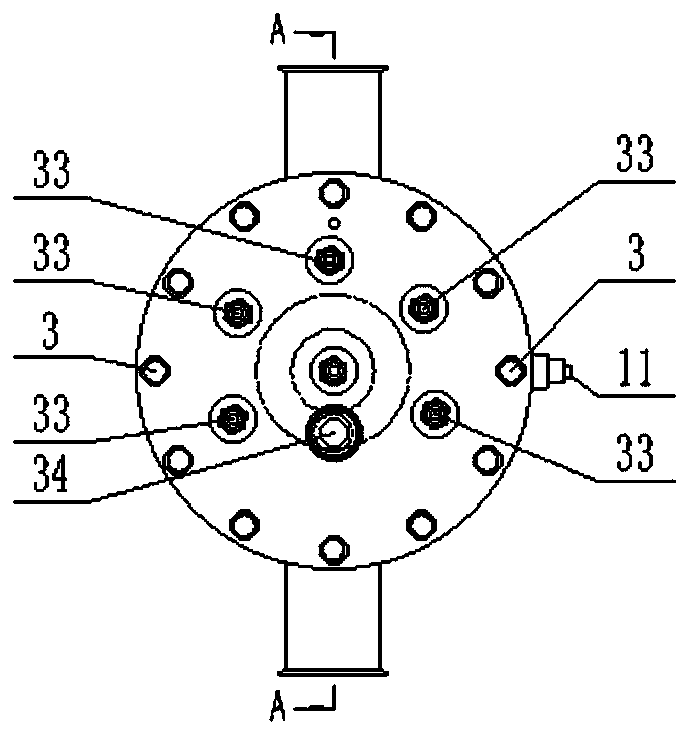

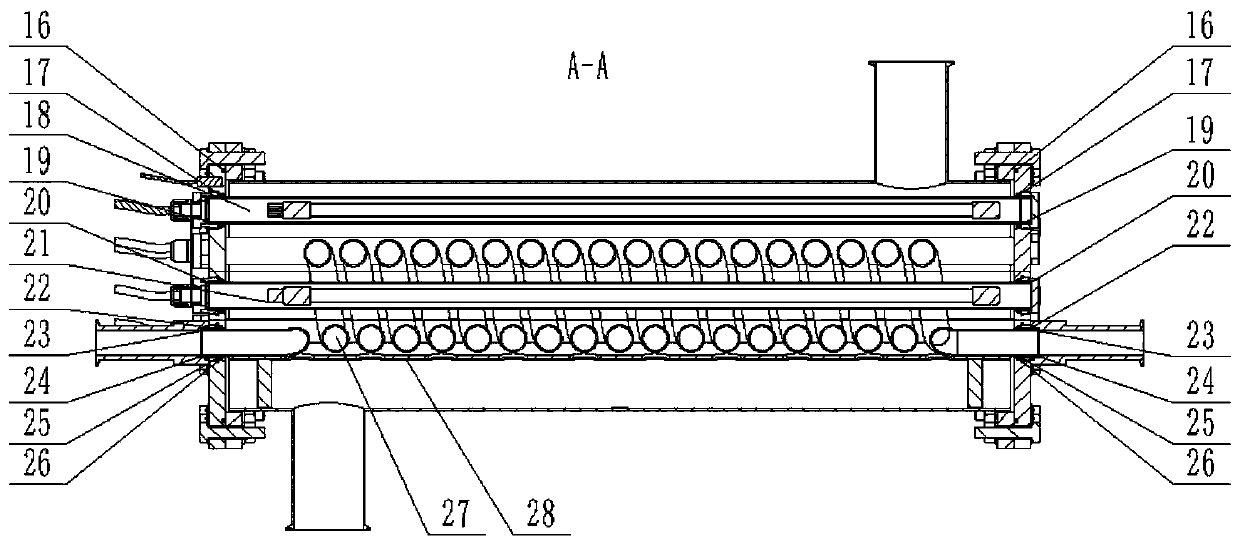

[0030] The fluid disinfection equipment consists of the second fluid inlet and outlet pipe 1, the first fluid inlet pipe 15, the first fluid outlet pipe 12, the ultraviolet lamp tube cable 2, the positioning bolt group 3, the waterproof cable fixing head 4, the reducing ring 5, the open quartz Casing sealing plug 6, temperature sensor and cable 7, inlet end plate 8, fasteners 9, outer tube 10, ultraviolet intensity sensor 11, outlet end plate 13, closed quartz sleeve plug 14, quartz sleeve Tube 18, ultraviolet lamp tube 21, spiral light-transmitting inner tube 27, flow guide support plate 28, end plate sealing ring 16, quartz casing sealing ring 19, quartz casing sealing gasket 17, quartz casing port gasket 20, spiral No. 1 sealing ring 25 of the shaped light-transmitting inner tube, No. 1 sealing ring gasket 26 of the spiral-shaped light-transmitting inner tube, No. 2 sealing ring 22 of the spiral-shaped light-transmitting inner tube, No. 2 sealing gasket 23 of the spiral-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com