Salifying preparation process of ibuprofen arginine

A preparation process, the technology of arginine, which is applied in the field of arginine ibuprofen salt preparation process, can solve the problems of unfavorable patient safety, difficulty in starting the reaction, long reaction time, etc., and achieve the benefits of patient safety and prevention of explosion-proof problems , the effect of short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

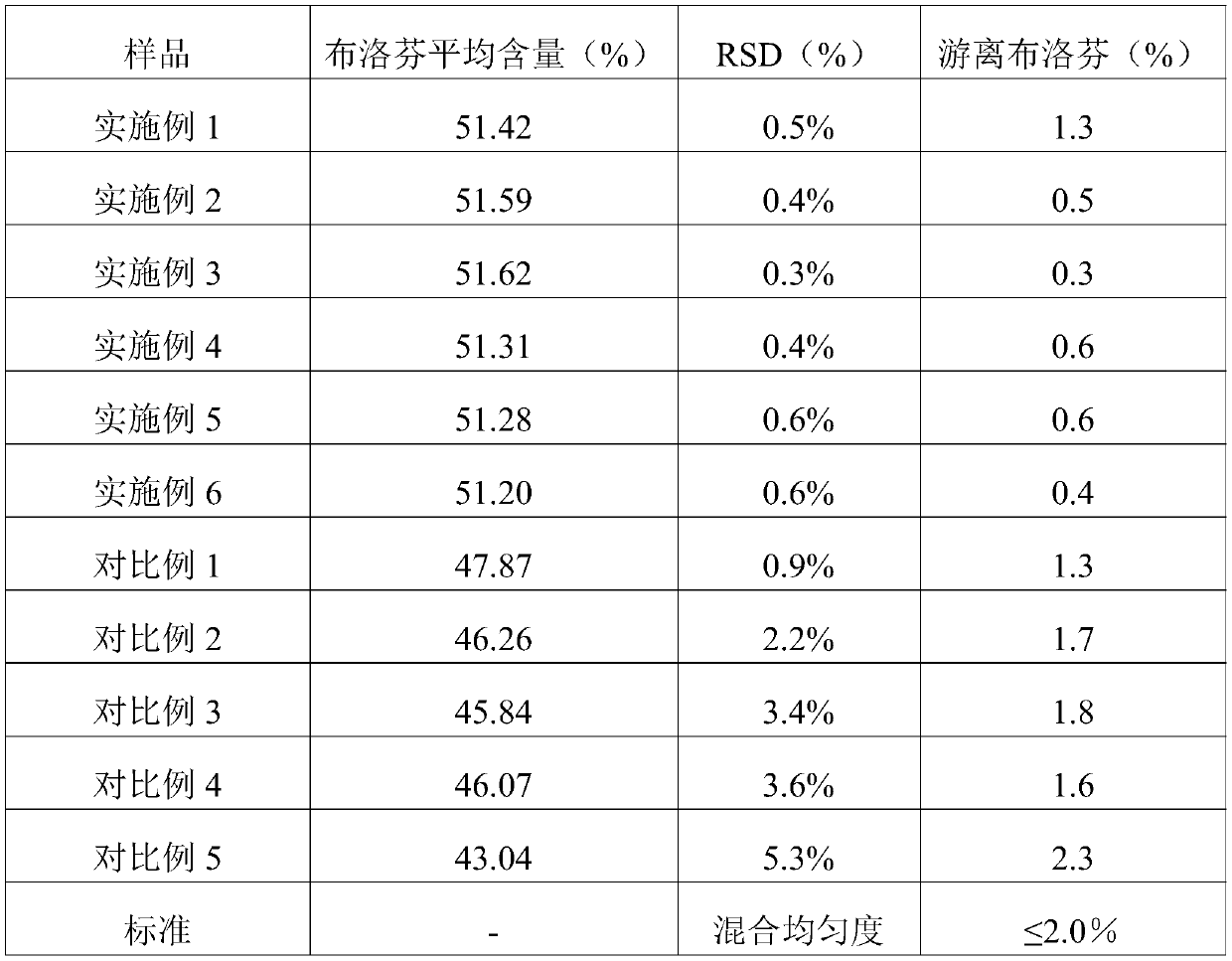

Examples

Embodiment 1

[0018] A preparation process for arginine ibuprofen salting: comprising the following steps: first heating water to 90°C, adding ibuprofen and heating for 30 minutes until melting, adding arginine at a stirring rate of 25 rpm, stopping heating, Stir for 10 minutes, then use residual temperature to carry out vacuum drying for 20 minutes to get final product, the vacuum degree is -0.10MPa, the weight ratio of the ibuprofen and arginine is 1:1, and the water consumption is the total weight of the ibuprofen and arginine 5%.

Embodiment 2

[0020] A preparation process for ibuprofen arginine salt: including the following steps: first heating water to above 120°C, adding ibuprofen and heating for 90 minutes until melting, adding arginine at a stirring rate of 100rpm, and stopping heating , stirred for 20min, and then vacuum-dried for 60min using residual temperature to get final product. The vacuum degree is -0.05MPa. The weight ratio of ibuprofen and arginine is 1:1.2, and the water consumption is ibuprofen and arginine total weight 15%.

Embodiment 3

[0022] A preparation process for ibuprofen arginine salt: including the following steps: first heating water to above 100°C, adding ibuprofen and heating for 60 minutes until melting, adding arginine at a stirring rate of 60rpm, and stopping heating , stirred for 15min, and then vacuum-dried for 40min using residual temperature to get final product, the vacuum degree is -0.08MPa, the weight ratio of said ibuprofen and arginine is 1:1.1, and the water consumption is the total amount of ibuprofen and arginine. 10% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com