Imitated bait and manufacturing method thereof

A technology for simulating fish and body, which is applied in artificial fishing bait, fishing, animal husbandry, etc., can solve the problems of poor refraction effect of plastic artificial fishing bait, insufficient fish attractiveness, short service life, etc., and achieves good elasticity and low cost. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

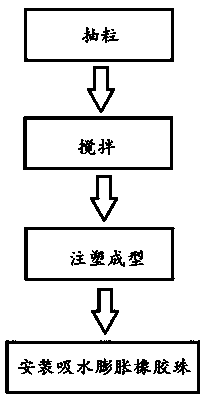

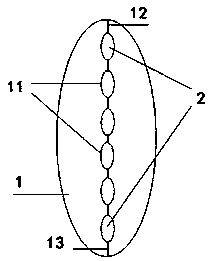

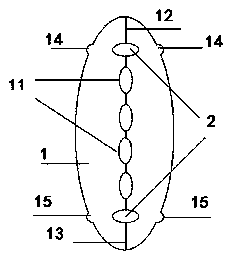

[0029] Such as figure 1 As shown, Example 1: A simulated fishing bait, including the following components according to the weight fraction: 30 parts of styrene, ethylene, butylene, and styrene block copolymer (SEBS for short); 58 parts of alkane oil; antioxidant 5 parts of 1076-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate; 1 part of antioxidant 168 tris(2.4-di-tert-butylphenyl) phosphite; 5 parts of water-swellable rubber; Its manufacturing process comprises the following steps:

[0030] Step 1, granulation: Styrene, ethylene, butylene, styrene block copolymer (SEBS for short); alkane oil; antioxidant 1076-(3,5-di-tert-butyl-4-hydroxyphenyl) N-octadecanyl propionate; Antioxidant 168 tris(2.4-di-tert-butylphenyl) phosphite is granulated to obtain recycled materials;

[0031] Step 2, mixing and stirring: before injection molding, add toner to the regenerated material, and mix and stir to obtain a mixture;

[0032] Step 3. Injection molding: Put the obtained mixt...

Embodiment 2

[0034] Example 2: A simulated fishing bait, which includes the following components according to the weight fraction: 20 parts of styrene, ethylene, butylene, and styrene block copolymer (SEBS for short); 70 parts of alkane oil; antioxidant 1076ß-( 3 parts of 3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate; 2 parts of antioxidant 168 tris(2.4-di-tert-butylphenyl) phosphite; water-swellable rubber 4 parts; its manufacturing process comprises the following steps:

[0035] Step 1, granulation: Styrene, ethylene, butylene, styrene block copolymer (SEBS for short); alkane oil; antioxidant 1076ß-(3,5-di-tert-butyl-4-hydroxyphenyl) N-octadecanyl propionate; antioxidant 168 tris(2.4-di-tert-butylphenyl) phosphite were granulated to obtain recycled materials.

[0036] Step 2, mixing and stirring: before injection molding, add toner to the regenerated material, and carry out mixing and stirring to obtain a mixed material.

[0037] Step 3. Injection molding: Put the obtained ...

Embodiment 3

[0039] Example 3: An artificial fishing bait, including the following components according to the weight fraction: 14 parts of styrene, ethylene, butylene, and styrene block copolymer (SEBS for short); 85 parts of alkane oil; antioxidant 1076ß-( 3 parts of n-octadecyl propionate; 4 parts of antioxidant 168 tris (2.4-di-tert-butylphenyl) phosphite; water-swellable rubber 3 parts; its manufacturing process comprises the following steps:

[0040] Step 1, granulation: Styrene, ethylene, butylene, styrene block copolymer (SEBS for short); alkane oil; antioxidant 1076ß-(3,5-di-tert-butyl-4-hydroxyphenyl) N-octadecanyl propionate; antioxidant 168 tris(2.4-di-tert-butylphenyl) phosphite were granulated to obtain recycled materials.

[0041] Step 2, mixing and stirring: before injection molding, add toner to the regenerated material, and carry out mixing and stirring to obtain a mixed material.

[0042] Step 3. Injection molding: Put the obtained mixture into the mold in the injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com