A preparation method for high waxy crude oil demulsifier with wax content not less than 20%

A crude oil demulsifier and wax content technology, applied in the direction of dehydration/demulsification by chemical methods, can solve the problems of poor dehydration effect, achieve strong safety, simple operation, and suitable for popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

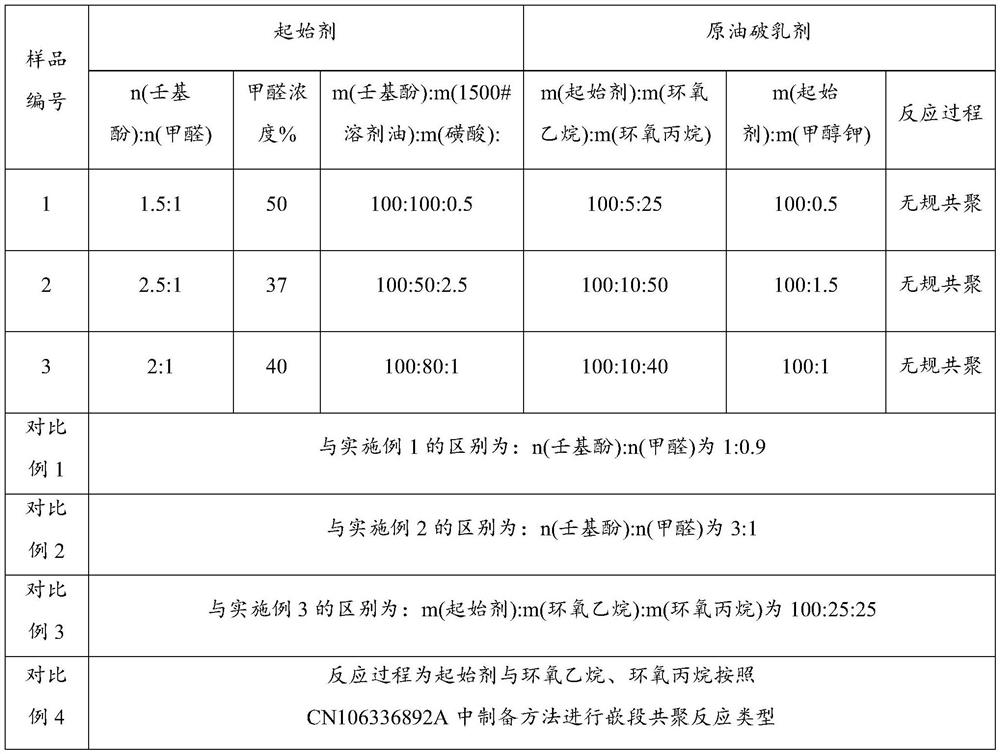

Examples

Embodiment 1

[0026] Embodiment 1: the preparation technology of crude oil demulsifier:

[0027] (1) Preparation of starter

[0028] In a four-neck flask equipped with a stirring device, an electric heating temperature control device, and a reflux condenser, add 1500# solvent oil, then add nonylphenol, and formaldehyde with a content of 37-50%, and heat up to 90-110°C. And add sulfonic acid, reflux reaction for 1-3 hours, remove excess water and solvent to obtain novolac polycondensate;

[0029] (2) Preparation of crude oil demulsifier

[0030] Add the uniformly mixed ethylene oxide and propylene oxide into the reaction kettle, vacuumize and replace with nitrogen for 2 to 4 times, start stirring and raise the temperature to 90-100°C, start the vacuum pump to vacuum, when the temperature continues to rise to 120°C Stop the vacuum, then put the novolac polycondensate and catalyst potassium methylate into the reactor, the reaction temperature is 130-140°C, the reaction is 0.5-0.8h, and the r...

Embodiment 2

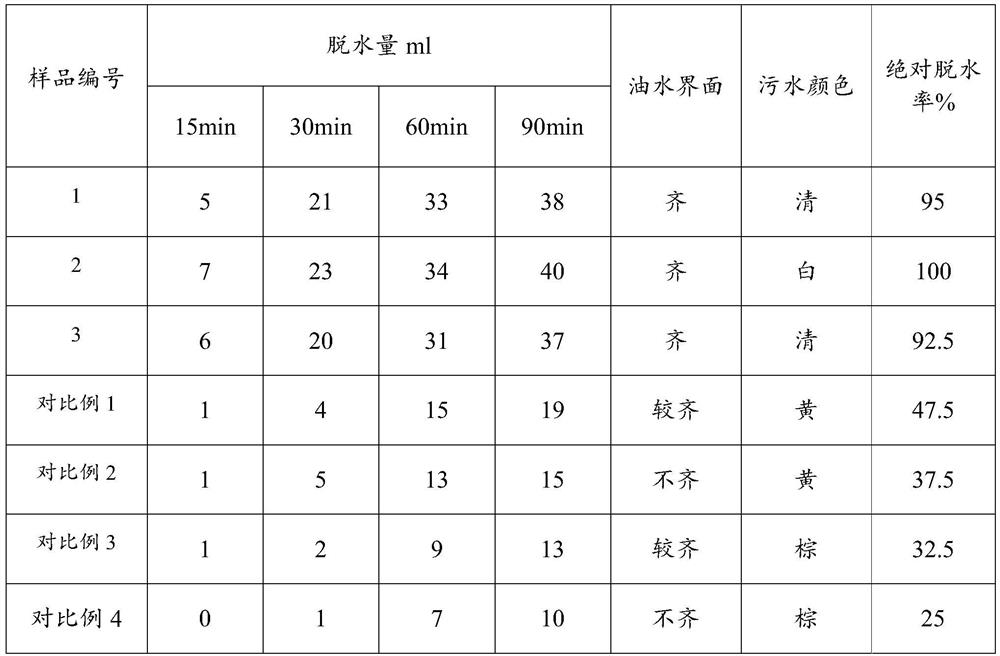

[0034] Example 2: Characterization

[0035] The high waxy crude oil that adopts in the present embodiment is used as experimental oil, and wax content is 23%, and colloidal asphaltenes content is 10-15%, and this crude oil water content (V / V) is 50%, that is, in 80ml emulsified crude oil The water content is 40ml, and the dehydration temperature is 75°C; the dosing concentration is 100ppm when the crude oil is dehydrated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com