Method for producing strains by extracting original strains from glossy ganoderma to convert into liquid

A technology of liquid strains and Ganoderma lucidum, which is applied in the field of transforming the original strains of Ganoderma lucidum into liquid production strains, can solve the problems of low production capacity of Ganoderma lucidum polysaccharides, and achieve the effects of centralized seed production, reduced equipment requirements, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

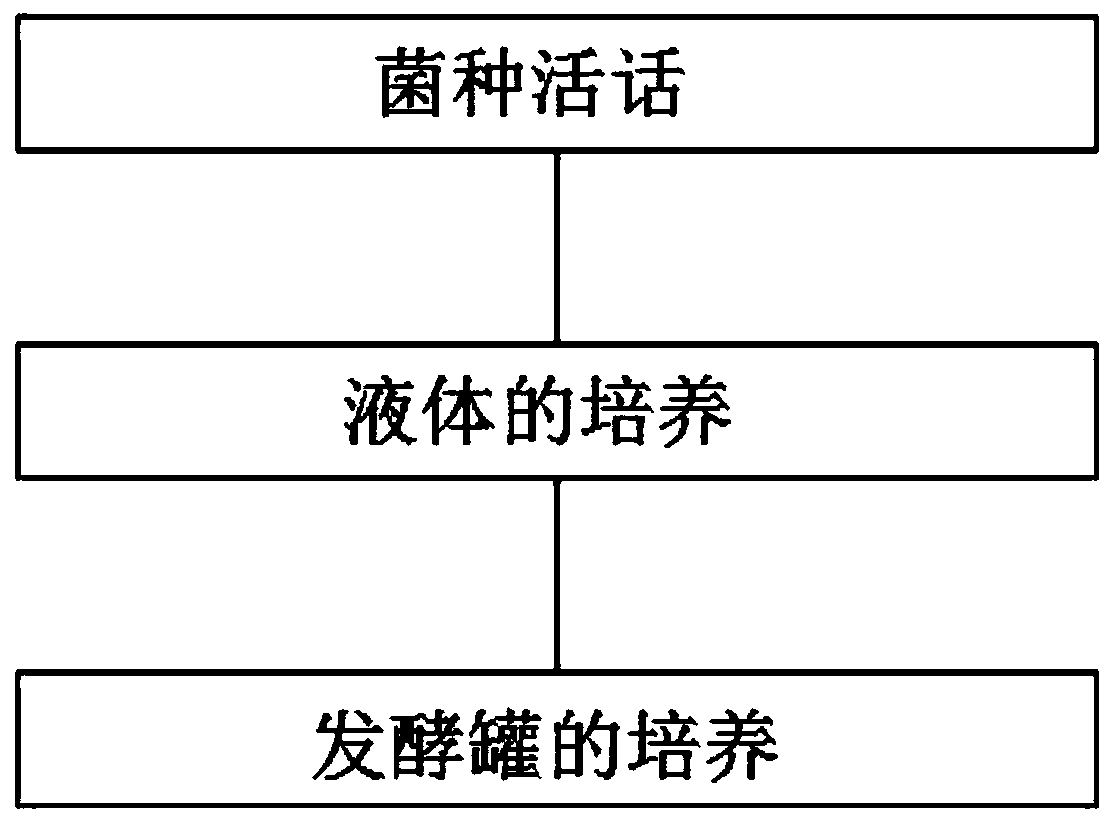

[0016] see figure 1 , the technical scheme of the method for extracting original strains of ganoderma to transform liquid production strains provided by the invention: the method for extracting original strains of ganoderma to transform liquid production strains, the ganoderma strains selected for testing are black ganoderma and purple ganoderma, Inoculate each Ganoderma lucidum strain on PDA medium, culture at 25°C for 10 days, and store at 4°C. The preparation method of the strain includes the following steps: Step 1: The activation of the strain is to cut out a 0.5cm Mycelial pieces of different sizes were inoculated in the middle of the slant medium, cultured for 7 days, then transferred once, and cultured at 25°C for 7 days before use;

[0017] Step 2: For liquid culture, the first is the preparation of the seed liquid. Take 2 to 3 pieces of activated bacteria with a size of 1 em in the basal medium, place them on a rotary shaker at 25°C and shake them at 180r / min for 7 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com