Vibration finishing protection device for blades

A protection device and blade technology, which is applied to the components of the pumping device for elastic fluid, the supporting element of the blade, the engine element, etc. Long service life and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

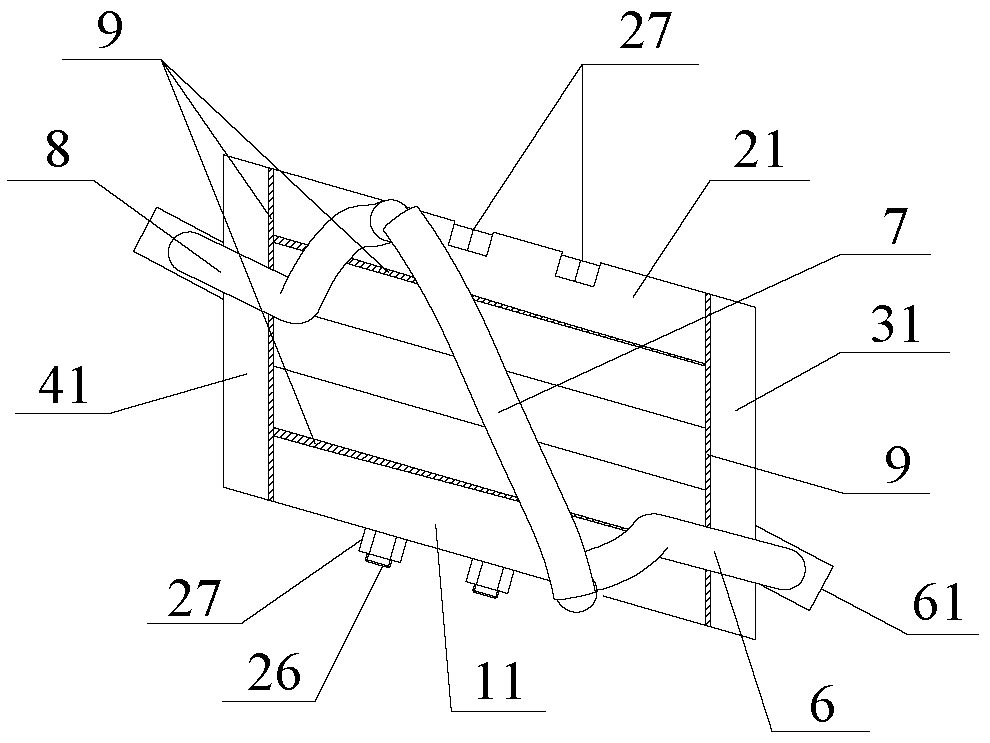

[0036] See Figure 1 to Figure 14 , a vibrating light decoration protection device for blades of the present invention, which includes a blade root protection part and a blade tip protection part, the blade root protection part cooperates with the blade root 5 wrapping the blade, and the top surface of the blade root protection part and the edge of the blade The top surface 4 of the plate is flush; the blade tip protection part includes the inlet edge protection reinforcement 6, the blade top protection reinforcement 7 and the outlet edge protection reinforcement 8 welded in sequence, and the ends of the inlet edge protection reinforcement 6 and the outlet edge protection reinforcement 8 They are respectively fixedly connected to the blade root protection part; the shapes of the inlet edge protection steel bar 6, the blade top protection steel bar 7 and the air outlet edge protection steel bar 8 are respectively in line with the profile of the air intake edge 2 of the blade bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com