Energy efficiency evaluation method of canned motor pump for heating

A shielded electric pump and evaluation method technology, applied in geometric CAD, computer aided design, design optimization/simulation, etc., can solve the problems of inaccurate energy efficiency of shielded electric pumps for heating, and failure to consider the internal energy change of the pumped liquid, etc. Achieve large heat dissipation and improve evaluation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

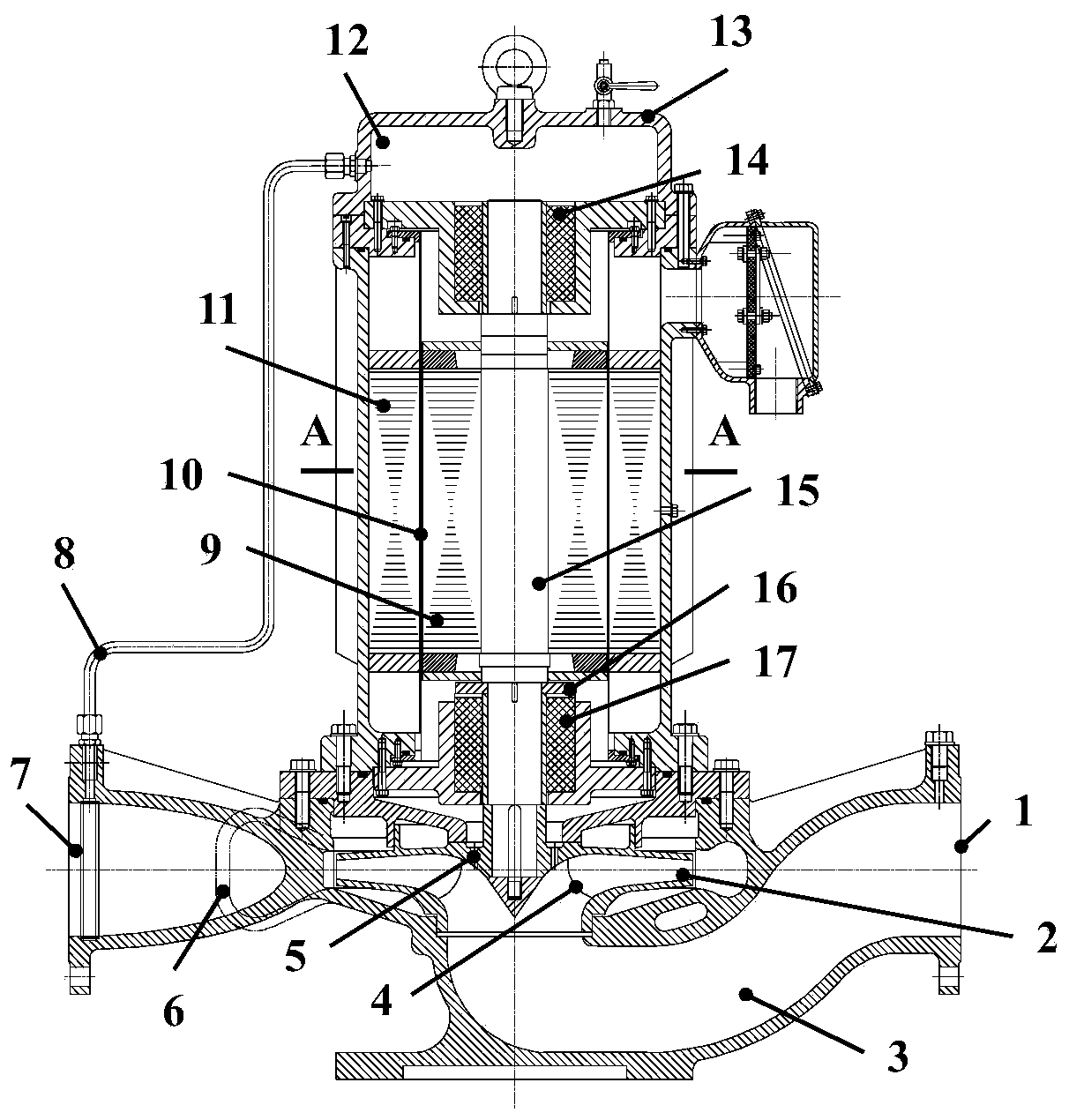

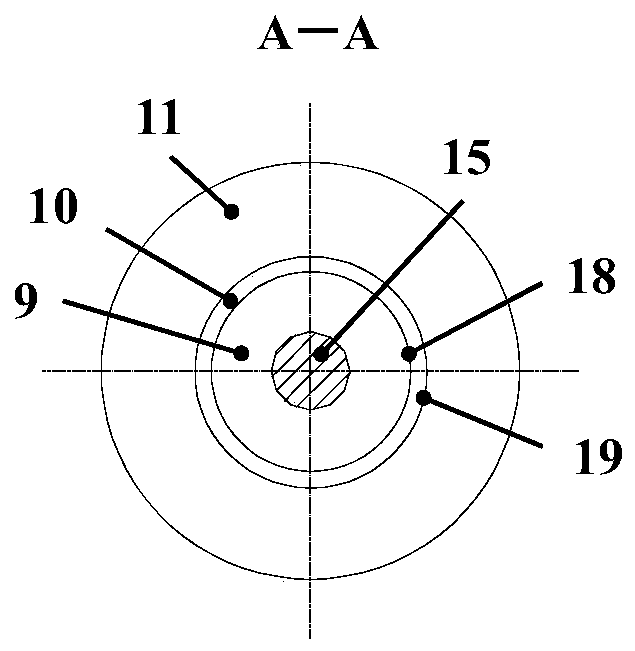

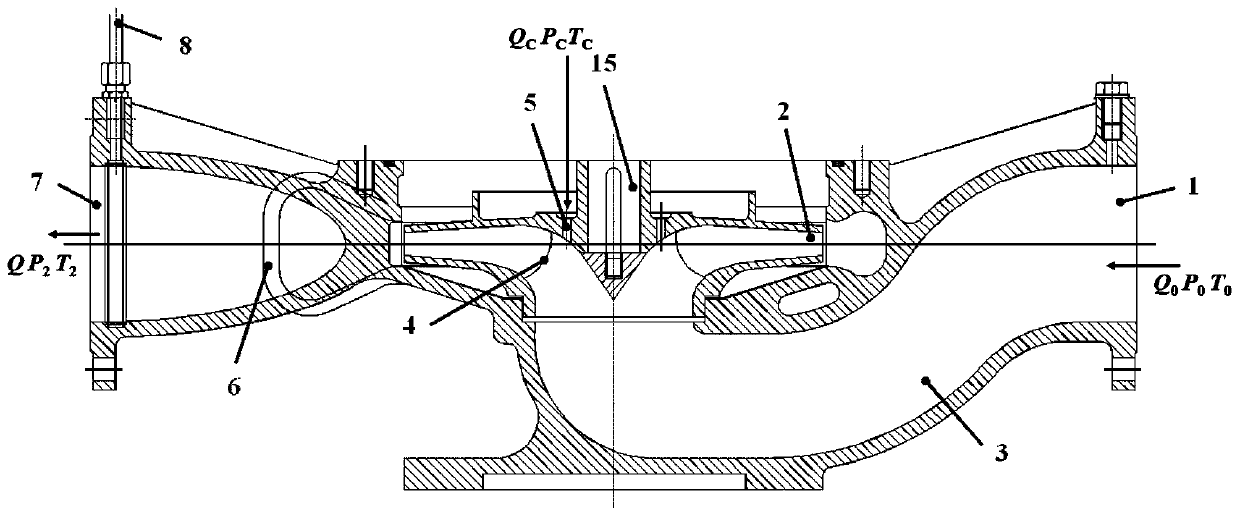

[0023] The principle and energy efficiency evaluation method of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] figure 1 It is a main sectional view of a shielded electric pump for heating provided by the present invention. The shielded electric pump includes a pump part and a motor part. The pump part mainly includes a pump inlet 1, an impeller 2, an inlet channel 3, a blade inlet 4, and an impeller Balance hole 5, volute 6 and pump outlet 7; the motor part mainly includes shaft 15, upper guide bearing 14, lower guide bearing 17, motor rotor 9, rotor shielding sleeve 18, motor stator 11, stator shielding sleeve 19, shielding sleeve clearance 10; wherein the stator shielding sleeve 19 is fixed on the motor stator 11, and the rotor shielding sleeve 18 is fixed on the motor rotor 9; the motor rotor 9 and the impeller 2 are fixedly connected to the shaft 15. There is relative motion between the shaft 15 and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com