A surface manganese doping and li-mn-po 4 Coated high-nickel positive electrode material and its preparation method and application

A cathode material, high-nickel technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of poor cycle performance and storage performance, accelerate the dissolution of transition metal ions, etc., to achieve a stable interface, a simple synthesis method, and improved Effects of Cyclic Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

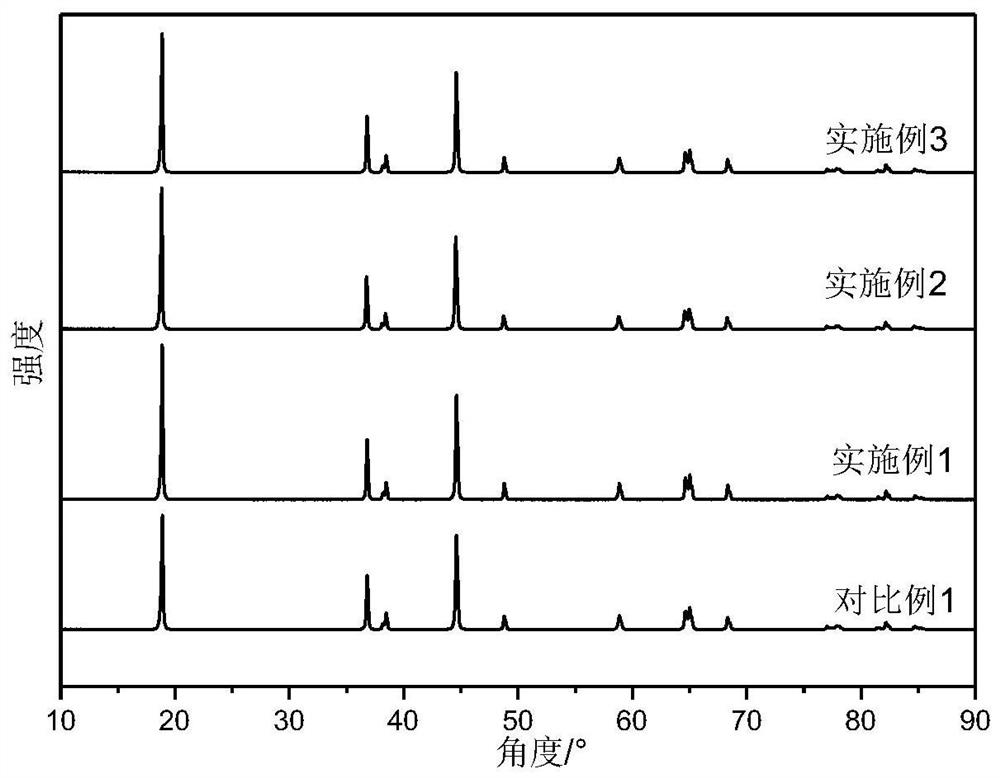

Embodiment 1

[0057] First, 0.0207g of Mn(CH 3 COO) 2 4H 2 O, 0.0074g of (NH 4 ) 2 HPO 4 Add to a beaker filled with 40mL of distilled water, stir for 30 minutes, then add 2g of Ni 0.9 co 0.1 (OH) 2 , stirred at room temperature for 5 hours, evaporated to dryness at 80° C., and then dried in a vacuum oven at 80° C. for 12 hours to obtain a modified precursor material. Lithium hydroxide (LiOH·H 2 O) Add it into the mortar, then add alcohol to grind, and then add the obtained modified precursor material into the mortar, in which LiOH·H 2 O and Ni 0.9 co 0.1 (OH) 2 ) in a molar ratio of 1.02:1, continue to grind until the alcohol evaporates to dryness, and finally obtain a solid powder. The solid powder is calcined in an oxygen atmosphere. First, it is pre-calcined at 500°C for 5 hours, and then it is heated to 720°C for 15 hours. min, the modified high-nickel ternary cathode material was obtained. The obtained modified high-nickel ternary cathode material is designated as 1-MP-N...

Embodiment 2

[0061] 0.0415g of Mn(CH 3 COO) 2 4H 2 O, 0.0149g of (NH 4 ) 2 HPO 4 Add to a beaker filled with 40mL of distilled water, stir for 30 minutes, then add 2g of Ni 0.9 co 0.1 (OH) 2 , stirred at room temperature for 5 hours, evaporated to dryness at 80° C., and then dried in a vacuum oven at 80° C. for 12 hours to obtain a modified precursor material. Lithium hydroxide (LiOH·H 2 O) Add it into the mortar, then add alcohol to grind, and then add the obtained modified precursor material into the mortar, in which LiOH·H 2 O and Ni 0.9 co 0.1 (OH) 2 ) in a molar ratio of 1.02:1, continue to grind until the alcohol evaporates to dryness, and finally obtain a solid powder. The solid powder is calcined in an oxygen atmosphere. First, it is pre-calcined at 500°C for 5 hours, and then it is heated to 720°C for 15 hours. min, the modified high-nickel ternary cathode material was obtained. The obtained modified high-nickel ternary cathode material is designated as 2-MP-NC91.

...

Embodiment 3

[0066] 0.0622g of Mn(CH 3 COO) 2 4H 2 O, 0.0223g of (NH 4 ) 2 HPO 4 Add to a beaker filled with 40mL of distilled water, stir for 30 minutes, then add 2g of Ni 0.9 co 0.1 (OH) 2 , stirred at room temperature for 5 hours, evaporated to dryness at 80° C., and then dried in a vacuum oven at 80° C. for 12 hours to obtain a modified precursor material. Lithium hydroxide (LiOH·H 2 O) Add it into the mortar, then add alcohol for grinding, and then add the prepared modified precursor material, in which LiOH·H 2 O and Ni 0.9 co 0.1 (OH) 2 ) in a molar ratio of 1.02:1, ground until the alcohol was evaporated to dryness, and finally obtained a solid powder. The solid powder is calcined in an oxygen atmosphere. First, it is pre-calcined at 500°C for 5 hours, and then it is heated to 720°C for 15 hours. min, the modified high-nickel ternary cathode material was obtained. The obtained modified high-nickel ternary cathode material is designated as 3-MP-NC91.

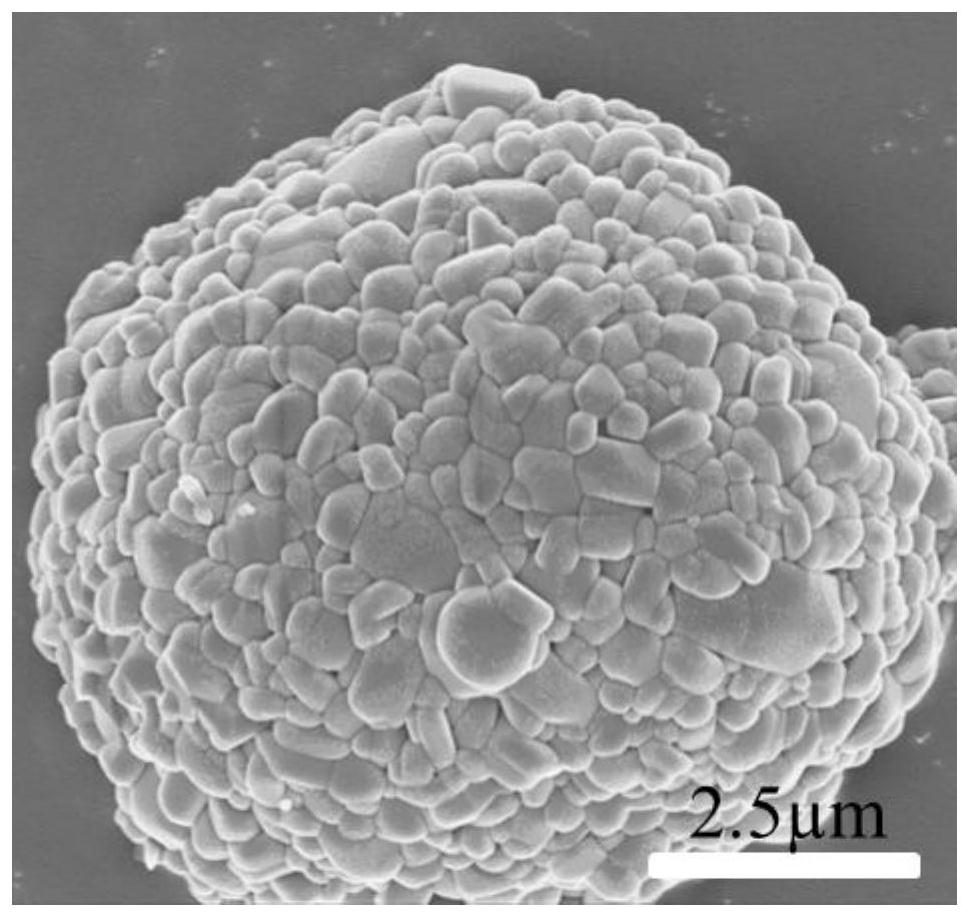

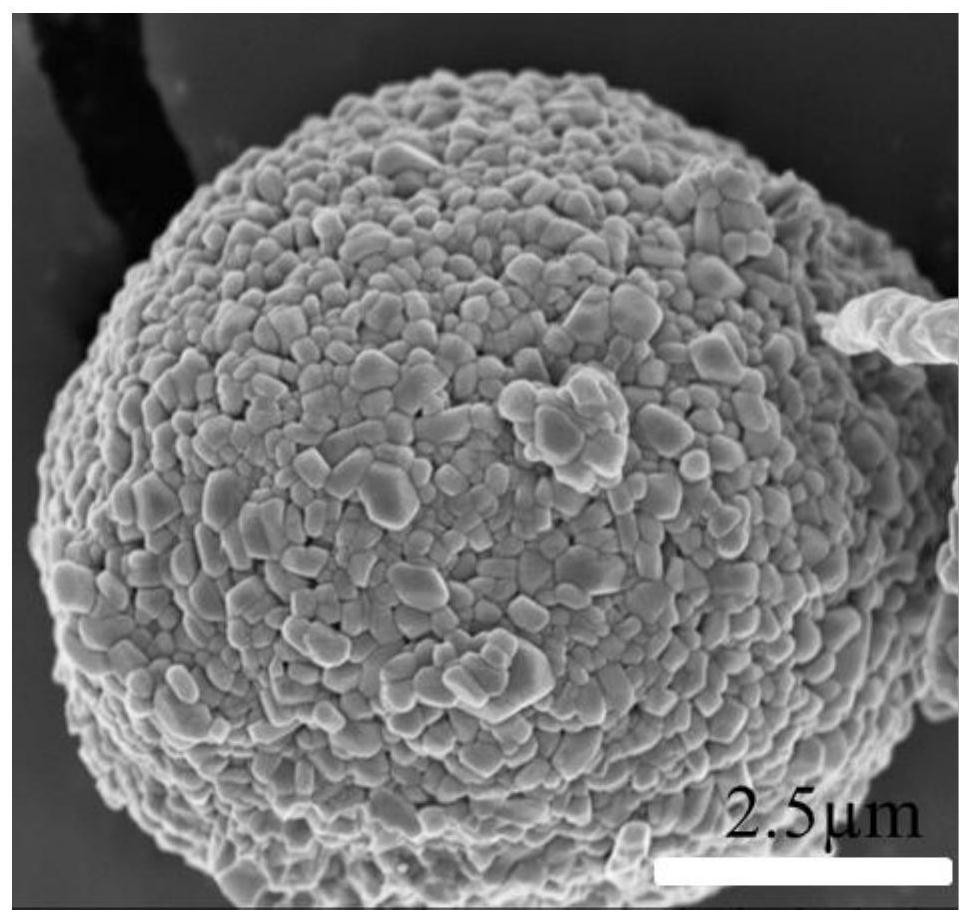

[0067] From fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com