Hemodialysis concentrated solution preparation device

A technology for hemodialysis and concentrate, applied in dialysis systems, transportation and packaging, mixer accessories, etc., can solve the problems of large storage space, insufficient disinfection, dead ends, etc., and achieve the effect of simple cleaning process, accurate preparation and accurate concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

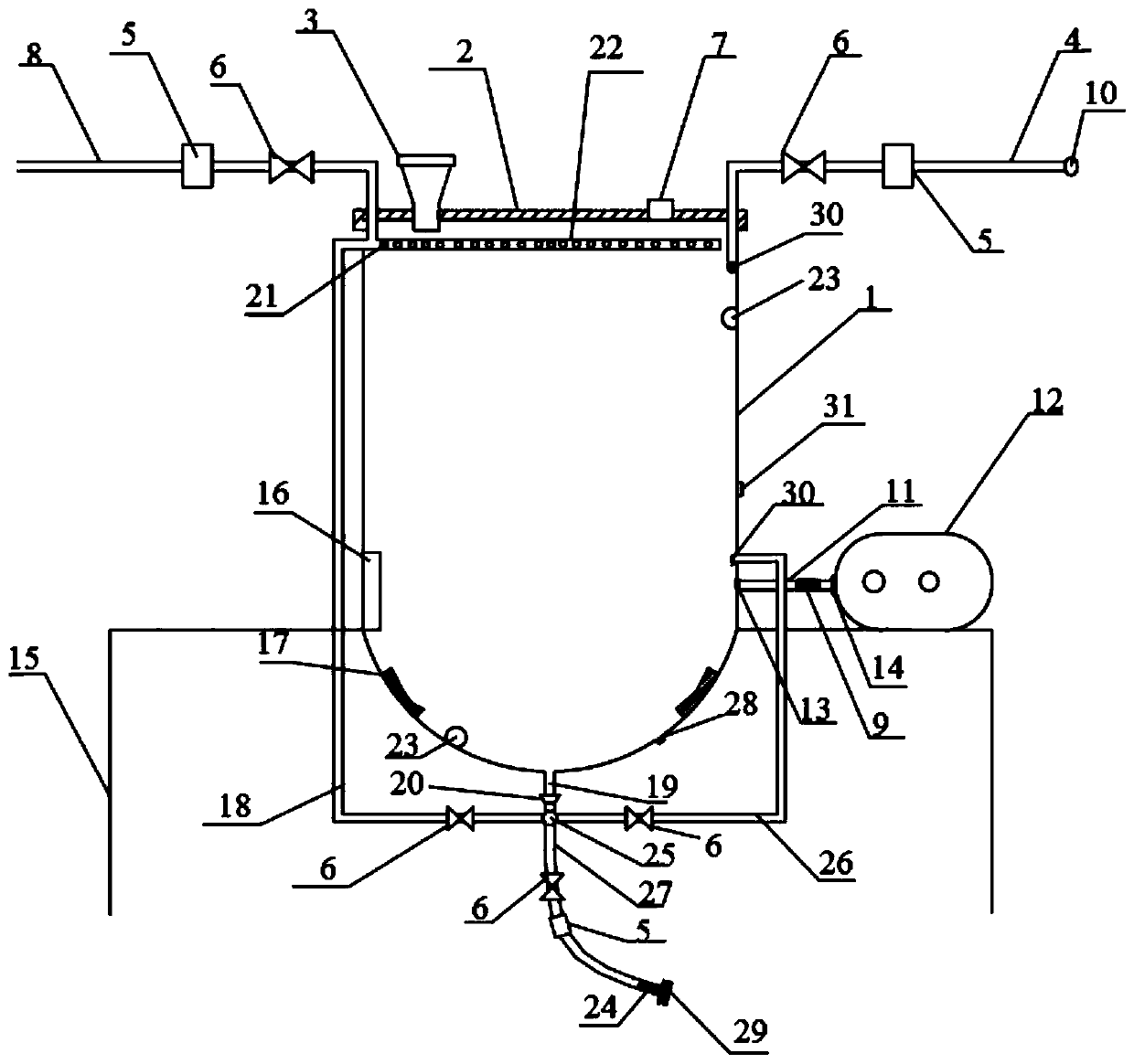

[0025] A hemodialysis concentrated solution preparation device, comprising a liquid mixing barrel 1 and a barrel cover 2, the barrel cover 2 is provided with a feed inlet 3, a liquid inlet pipeline 4 and a disinfectant pipeline 8, and the upper end opening of the feed inlet 3 is larger than The funnel shape at the lower end is more convenient when adding the dry powder for preparing the dialysis concentrate into the liquid distribution barrel 1; the end of the liquid inlet pipe 4 extending into the liquid distribution barrel 1 is provided with a guide tube 30, and the guide tube 30 Close to the inner wall of the liquid dispensing barrel 1, the guide pipe 30 extending into the barrel adopts a circular direction along the barrel wall, which can quickly form a vortex. The annular pipe 22 is provided with a plurality of liquid outlet holes 21, and the disinfectant pipe 8 is connected to the annular pipe 22; when the liquid dispensing barrel 1 is sterilized, the disinfectant enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com