A kind of Venturi tube and its application

The technology of a venturi tube and a throat tube, which is applied to the venturi tube and its application field, can solve the problems of blockage of the liquid nozzle, affecting the washing effect, and easy scaling of the shrinking tube, so as to achieve a small impact on the structure and enhance the atomization effect. , the effect of taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

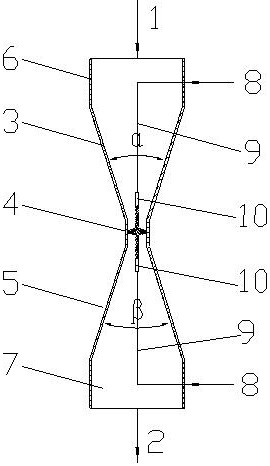

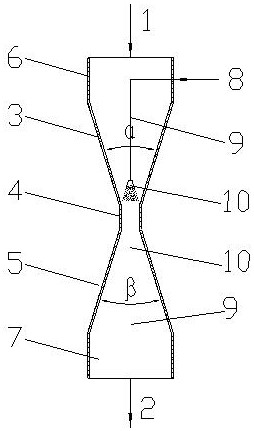

[0039] the present invention figure 1 The structural Venturi tube is used for flue gas dust removal, and the flue gas volume is 80Nm 3 / h, the dust content is 300g / m 3 . The diameter of the throat in the Venturi tube is 30 mm, the length of the throat is 60 mm, the cone angles of the contraction section and the diffusion section are both 20°, the lengths of the contraction section and the diffusion section are both 60 mm, and the lengths of the inlet and outlet straight sections are 20mm. A group of nozzles are arranged in the venturi tube along the axial direction, the vertical distance between the two nozzles is 40mm, the opening diameter of each nozzle is 15mm, the ratio of the total opening area of each nozzle to the throat cross-sectional area is 0.25, the opening The hole angle is 90°. The ratio of liquid flow to flue gas flow is 0.2~5 (L / Nm 3 ), after being washed by the Venturi tube of the present invention and treated by the subsequent screen demister, the dust...

Embodiment 2

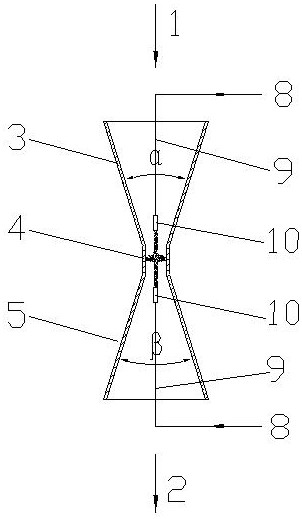

[0043] the present invention figure 2 The Venturi tube is used in flue gas desulfurization, and the flue gas volume is 80000Nm 3 / h, SO in flue gas 2 The concentration is 980mg / m 3 . The diameter of the throat in the Venturi tube is 1000mm, the length of the throat is 1500mm, the cone angles of the constriction section and the divergence section are both 10°, and the lengths of the constriction section and the divergence section are both 2000mm. A group of nozzles is installed in the venturi tube along the axial direction, the vertical distance between the two nozzles is 2000mm, the hole diameter on the nozzle is 30mm, the ratio of the total opening area of each group of nozzles to the throat cross-sectional area is 0.3, and the opening angle is 80 °~100°. The ratio of liquid flow to flue gas flow is 0.2~5 (L / Nm 3 ), after being washed by the Venturi tube of the present invention and treated by the subsequent demister, the SO in the flue gas 2 The concentration is 10m...

Embodiment 3

[0047] the present invention figure 1 The venturi tube is used in the production of alkylated gasoline, where the gas is 80Nm 3 / hC 4 A mixture of alkanes and olefins, the liquid is 98% concentrated sulfuric acid, concentrated sulfuric acid is used as a catalyst, and at a reaction temperature of 10°C, C 4 Alkenes and alkenes are produced through the alkylation reaction to produce high-octane gasoline components. The diameter of the throat in the Venturi tube is 30mm, the length of the throat is 60mm, the cone angles of the contraction section and the diffusion section are both 20°, the lengths of the contraction section and the diffusion section are both 60mm, and the lengths of the inlet and outlet straight sections are 20mm. A group of nozzles are arranged in the venturi tube along the axial direction, the vertical distance between the two nozzles is 30mm, the hole diameter on each nozzle is 15mm, the ratio of the total opening area on each nozzle to the throat cross-sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com