Graded pearl screening equipment and using method thereof

A sieving equipment and grading technology, applied in the field of grading pearl sieving equipment, can solve problems such as large differences in pearl size, difficult pearl sieving, and difficult pearl sieving and classification, achieving stable transmission process, high efficiency and cost , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

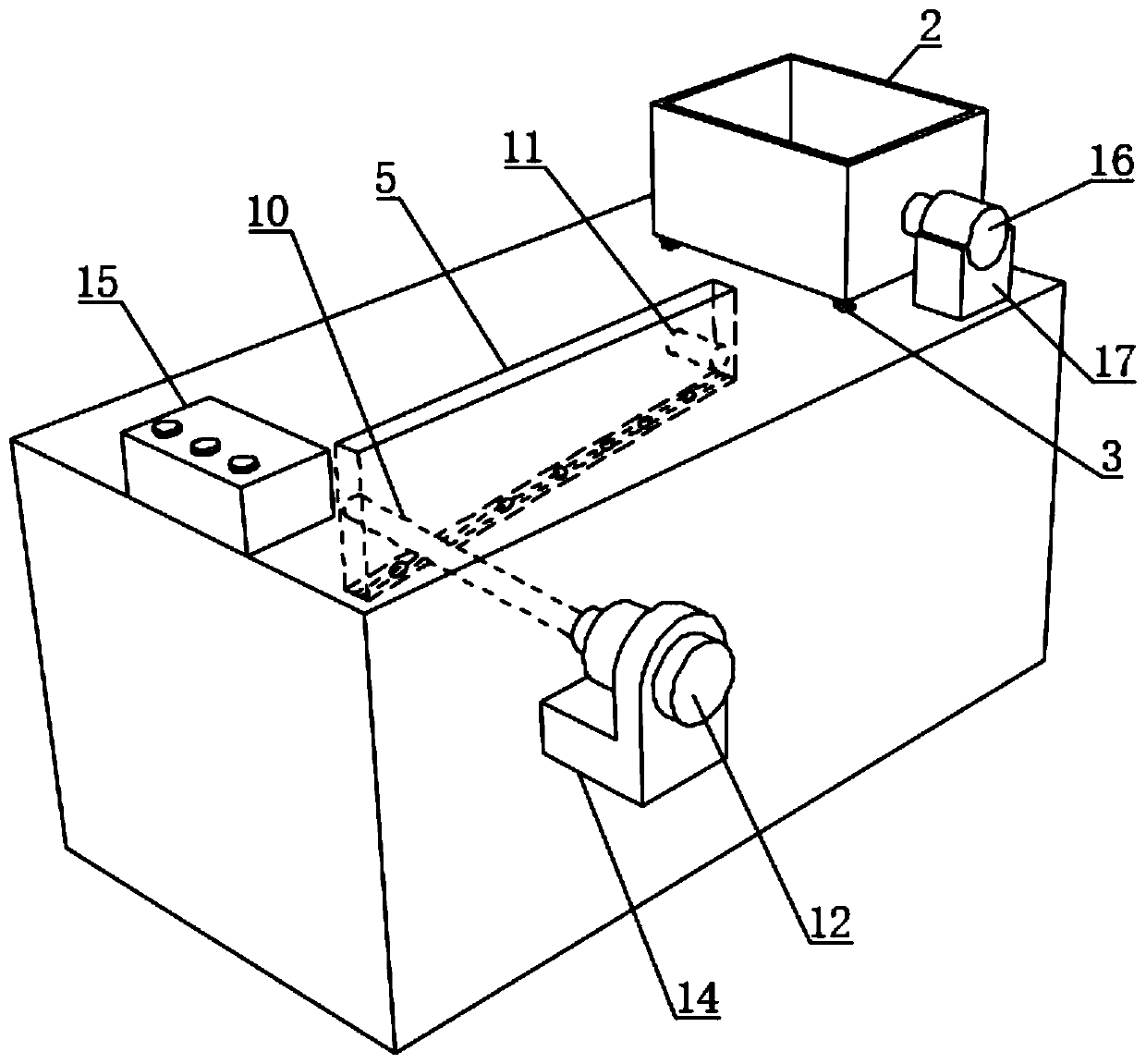

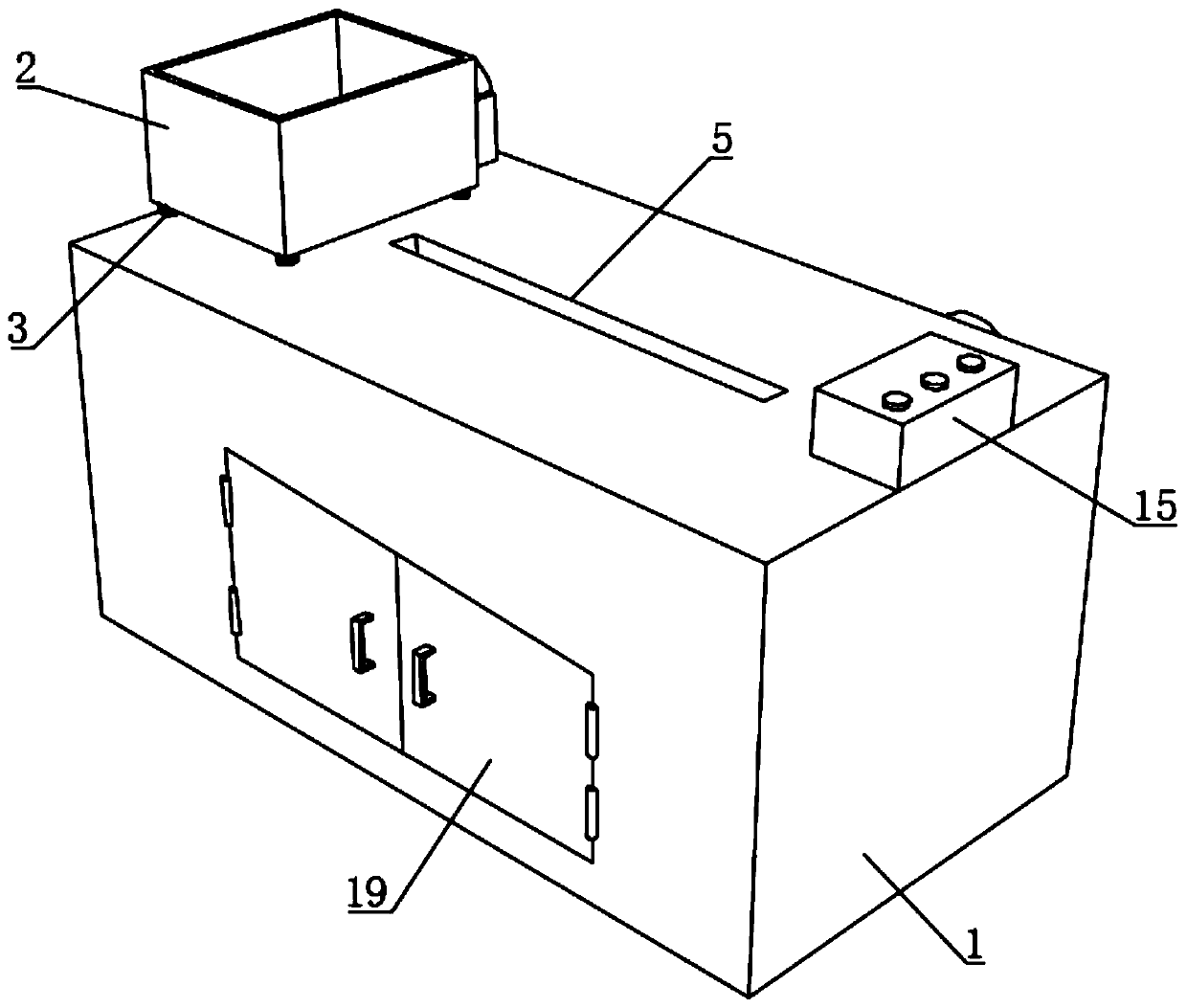

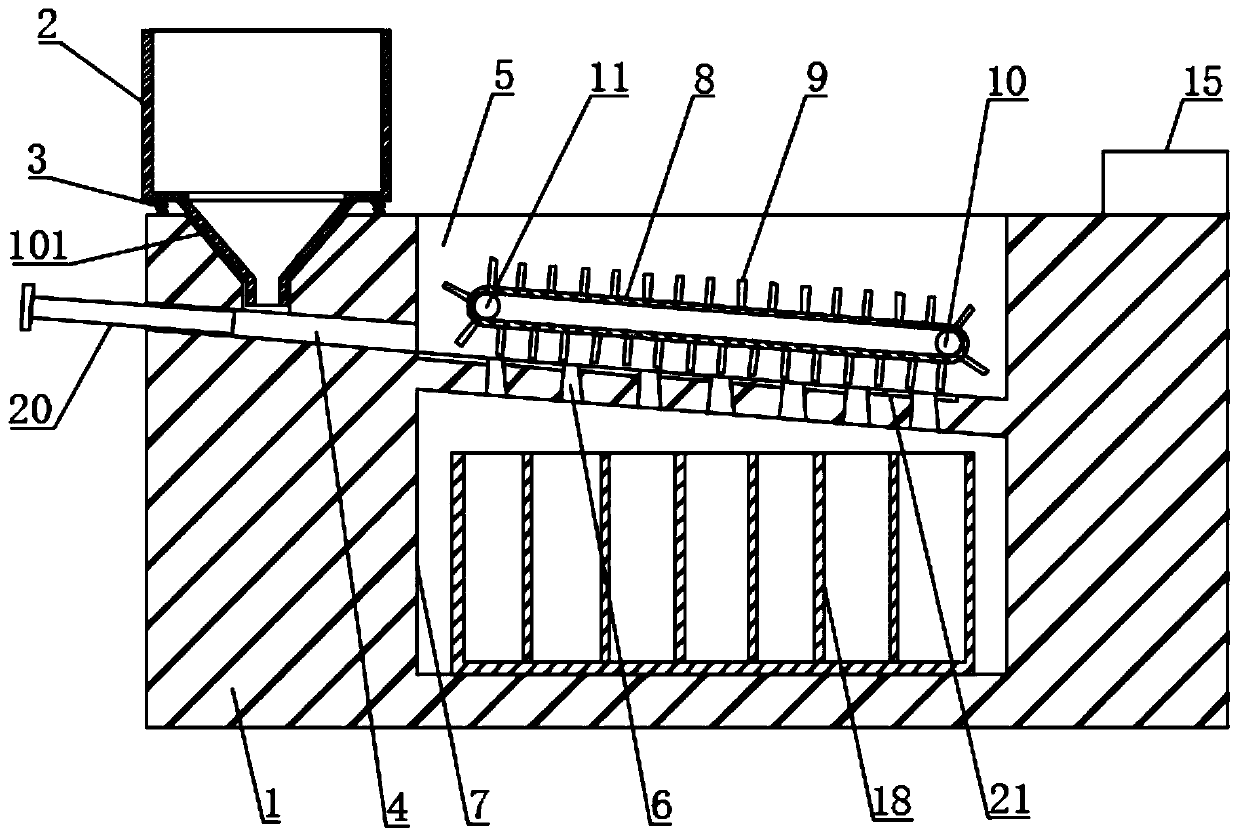

[0042] see figure 1 and figure 2 , a kind of graded pearl screening equipment, including an operation platform 1, a vibrating feeder is arranged above the operation platform 1, and a grading groove 5 is opened on the upper end of the operation platform 1, please refer to image 3 , the left side wall of the console 1 is provided with a circular passage 4, and the inner bottom surface of the grading tank 5 is provided with a plurality of evenly distributed feeding troughs 6, and the upper notches of the plurality of feeding chute The direction of 4 gradually increases, and there is a collection chamber 7 inside the operation table 1. The collection chamber 7 is located on the lower side of the feeding chute 6, and the collection chamber 7 communicates with the feeding chute 6. The inside of the grading chute 5 is provided with a classification transmission. mechanism.

[0043] see image 3 The grading transmission mechanism includes a driving wheel 10 and a driven wheel 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com