Production method of industrial monoammonium phosphate

A production method, monoammonium phosphate technology, applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of long production cycle and low overall benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

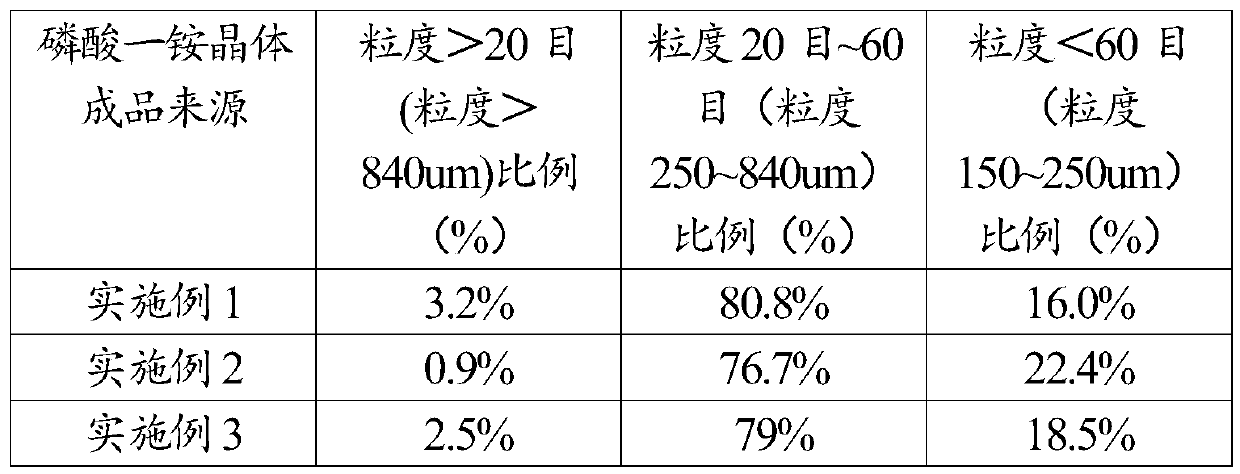

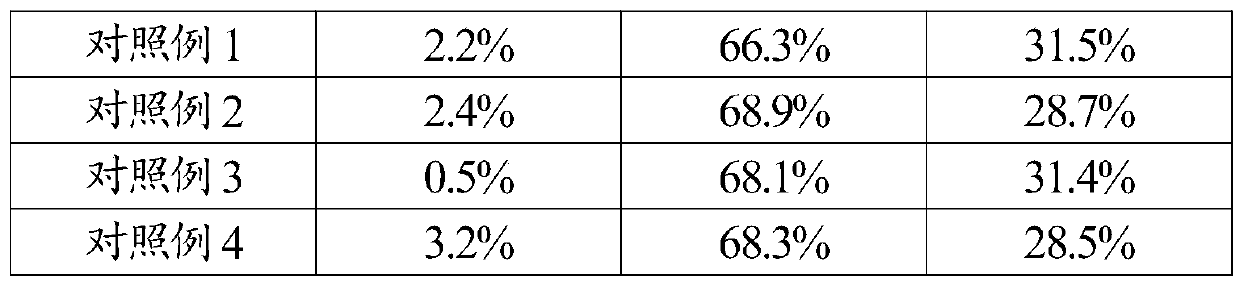

Examples

Embodiment 1

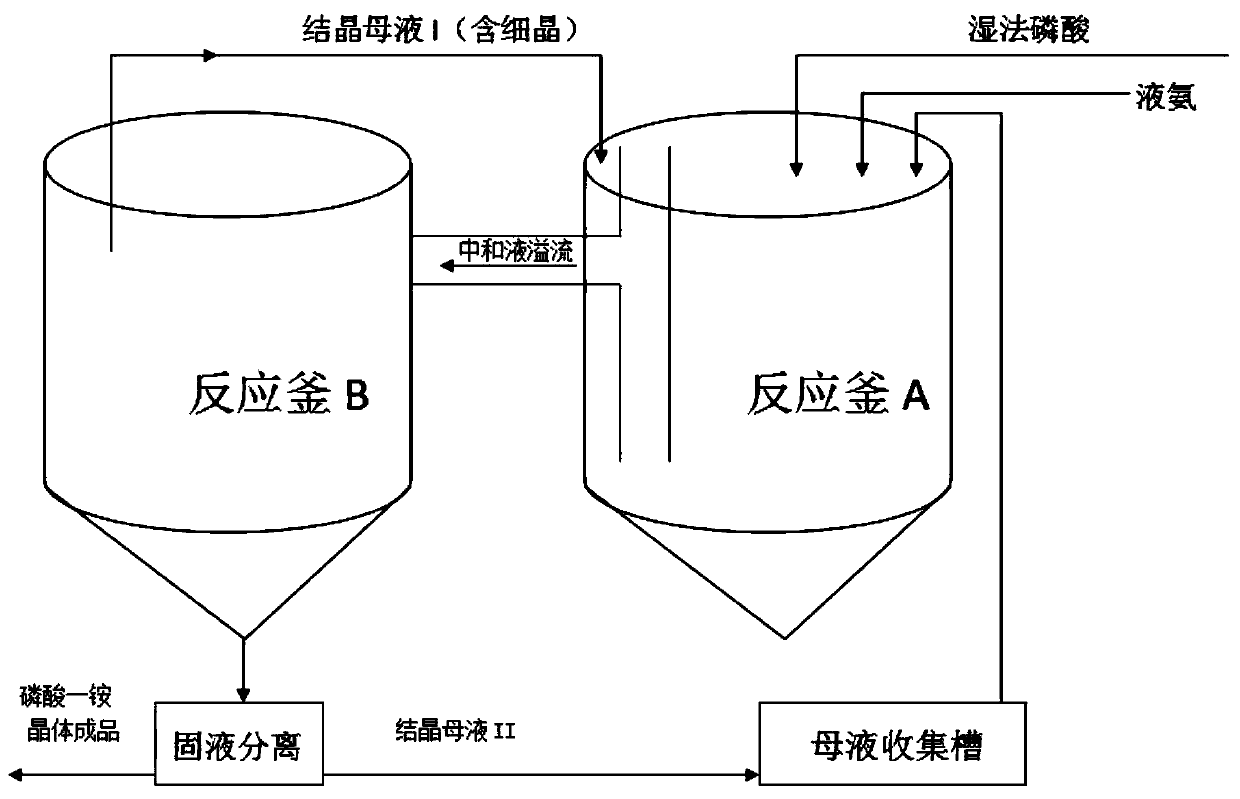

[0035] Such as figure 1 Shown, a kind of production device of industrial grade monoammonium phosphate, comprises the reactor A and reactor B that middle part communicates; Said reactor A is provided with liquid ammonia delivery pipeline and wet-process phosphoric acid delivery pipeline; Said reactor B The lower part is connected to the solid-liquid separation device, and the solid-liquid separation device is connected to the mother liquid collection tank for collecting the crystallization mother liquid II, and the mother liquid collection tank is connected to the crystallization mother liquid II delivery pipe, and the outlet of the crystallization mother liquid II delivery pipe is set at the reaction kettle A above, used to transport the crystallization mother liquor II to the reactor A; the upper part of the reactor B is provided with a crystallization mother liquor I conveying pipe, and the outlet of the crystallization mother liquor I conveying pipe is arranged on the reacto...

Embodiment 2

[0047] The only difference with Example 1 is:

[0048] In the step (1) and step (3), the stirring speed is 31r / min, and the temperature is 100°C;

[0049]In the step (2), the neutralization solution is stirred and settled at a stirring speed of 25 r / min; the temperature of the reaction process is 90°C.

Embodiment 3

[0051] The only difference with Example 1 is:

[0052] In the step (1) and step (3), the stirring speed is 33r / min, and the temperature is 105°C;

[0053] In the step (2), the neutralization liquid is stirred and settled, and the stirring speed is 27r / min; the temperature of the reaction process is 95°C;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com