A fast humidifying device for loose fibers

A humidification device and loose fiber technology, applied in liquid/gas/steam fiber/sliver/roving treatment, equipment configuration for processing textile materials, processing textile material carriers, etc., can solve the requirements that cannot meet the requirements of recycling and dust removal, and cannot guarantee humidification Uniformity, unable to meet the requirements of moisture regain, etc., to achieve the effect of fast speed, conducive to recycling, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

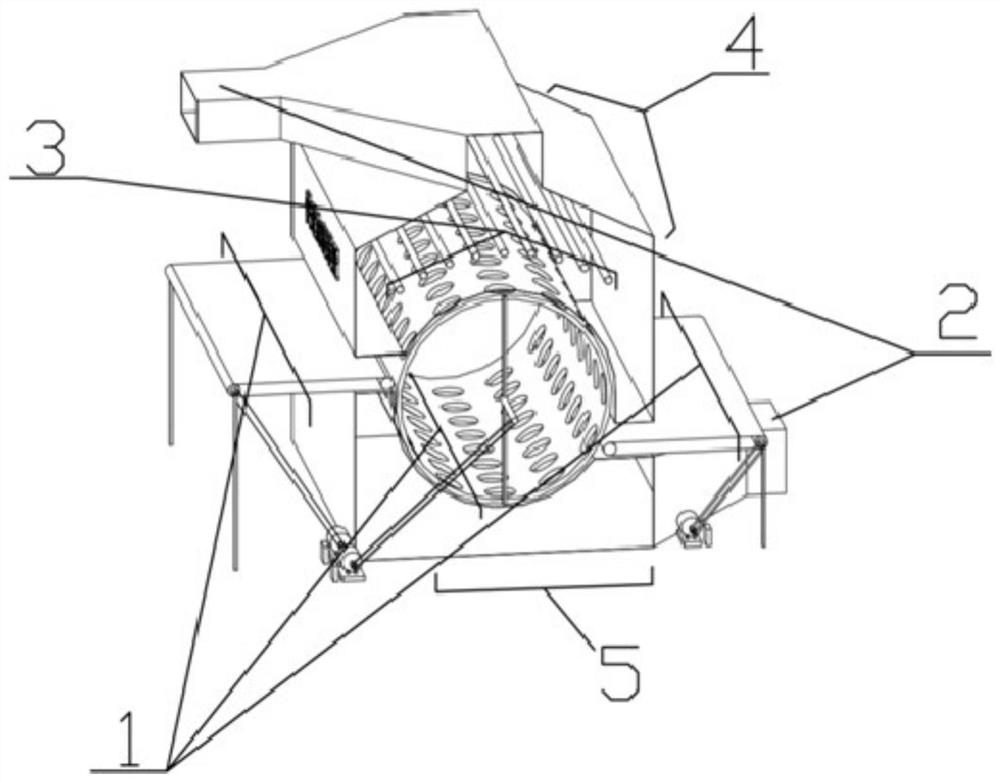

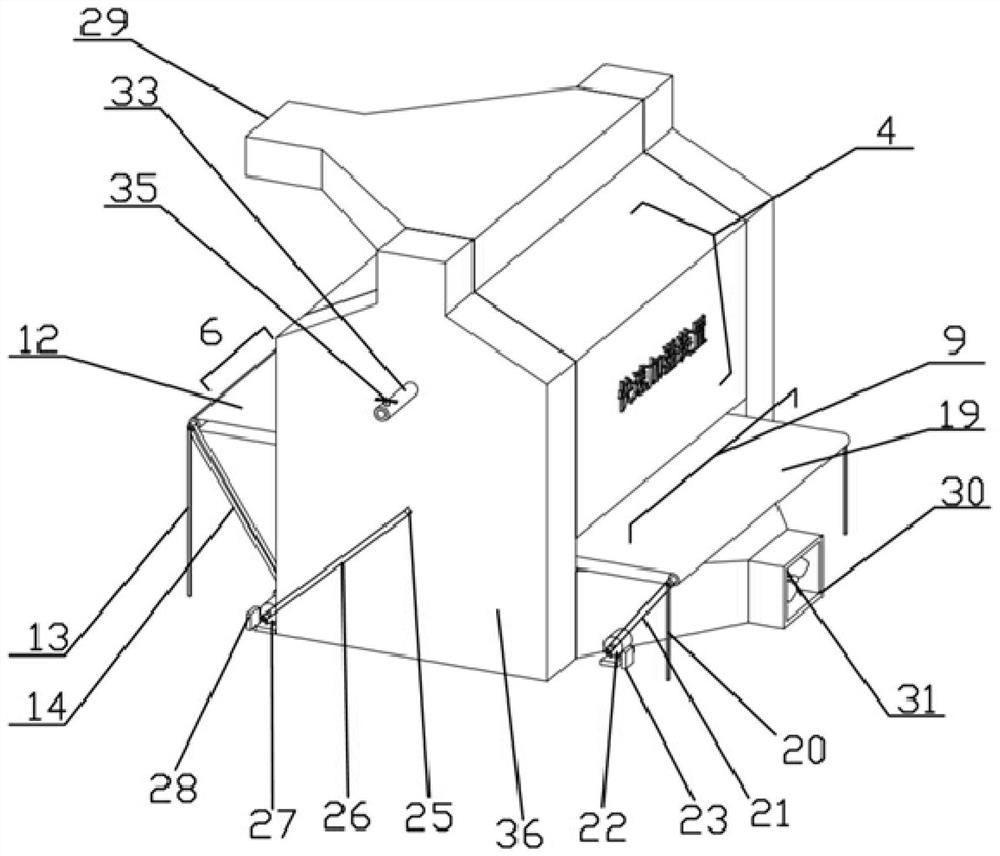

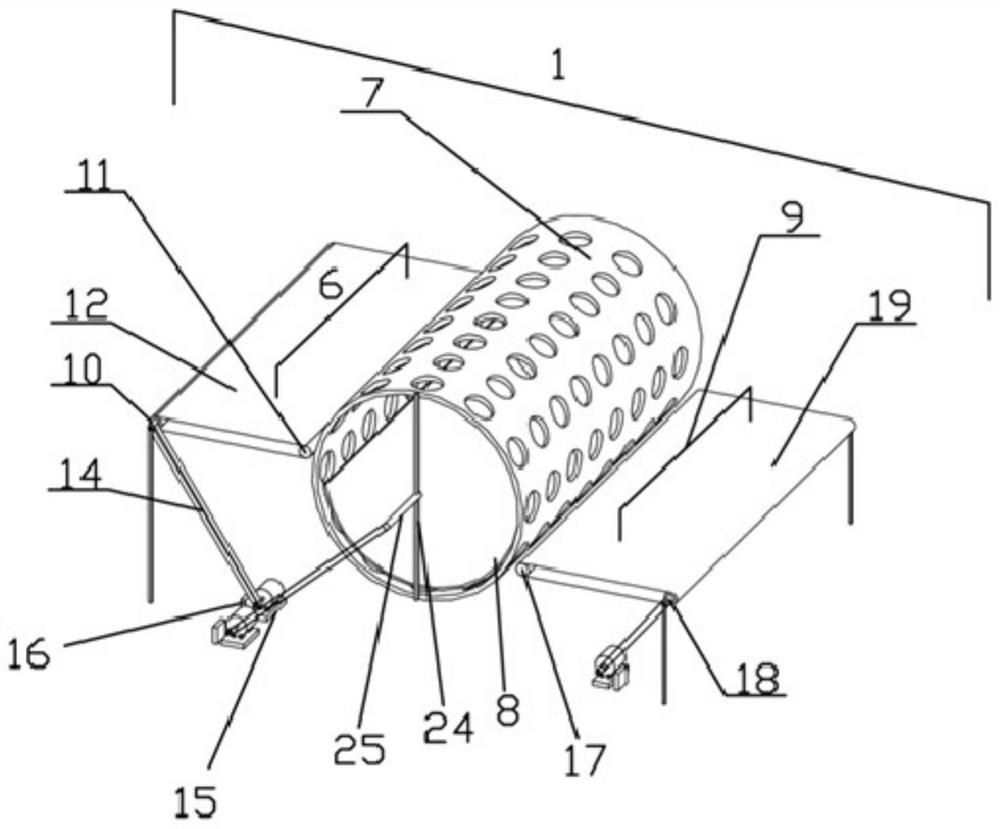

[0039] as attached figure 1 with 2 As shown, a loose fiber rapid humidification device is composed of fiber transmission system 1, humidification system 2, temperature control system 3, cover plate protection system 4, base 5, fiber transmission system 1, humidification system 2, temperature control system 3 , Cover protection system 4 are all arranged on the base 5. The loose fiber passes through the fiber conveying system 1, and the humidifying system 2 and the temperature control system 3 work together to make the loose fiber coming out of the fiber conveying system 1 have an appropriate moisture regain, so that it can meet the requirements of the next process, and the cover plate protection system 4 play a certain protective role. The bulk fiber fast humidifying device is a left and right closed whole, the bulk fiber enters the machine f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com