Robot precision compensation method based on parameter dimension reduction identification

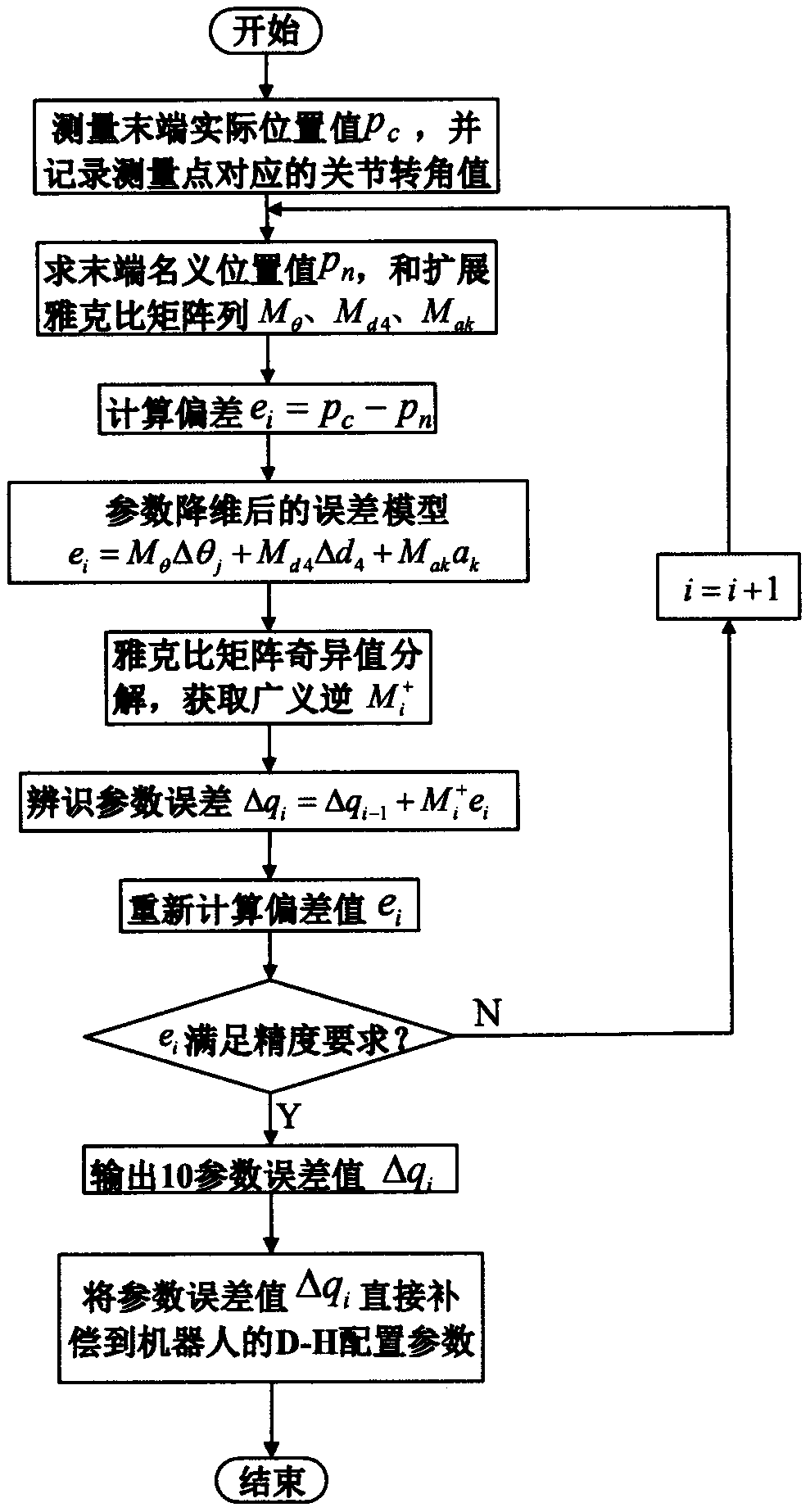

An accuracy compensation and robot technology, applied in the field of robot calibration, can solve the problem that the control system is not open to the outside world and cannot compensate for the D-H parameter error, etc., and achieves the effect of improving absolute positioning accuracy, reducing position error, and reducing the amount of identification calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

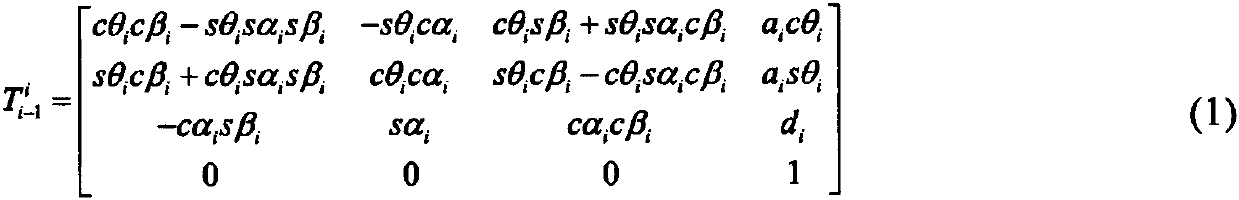

[0023] Embodiment: According to the structural parameters of the robot and the establishment principle of the homogeneous transformation matrix, the kinematic relationship between two adjacent rods of the Kawasaki RS010NA six-degree-of-freedom industrial robot is established. The kinematic relationship between two adjacent bars is:

[0024]

[0025] In formula (1), s and c are simplified forms of sin and cos respectively, θ i is the joint rotation angle, a i is the joint torsion angle, d i is the joint offset, β i is the rotation angle around the y-axis.

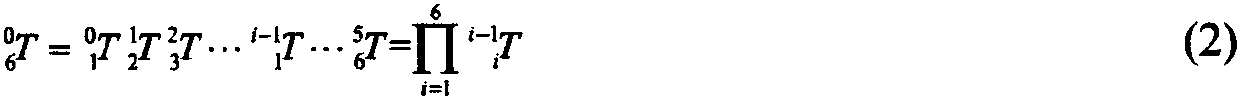

[0026] For a six-degree-of-freedom industrial robot, the error in each joint coordinate system is transferred to the end of the robot, and the homogeneous transformation matrix at the end of the robot is obtained as:

[0027]

[0028] In formula (2) represents the homogeneous transformation of the link from the base coordinates to the ends, arrive represents the link homogeneous transformation of adjacent lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com