Large container part leakage detection system and leakage detection method thereof

A technology for large containers and components, which is applied in the field of leak detection systems for large container components, can solve problems such as restrictions on the use of ammonia emissions, and achieve the effects of accurate judgment, short cycle time, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

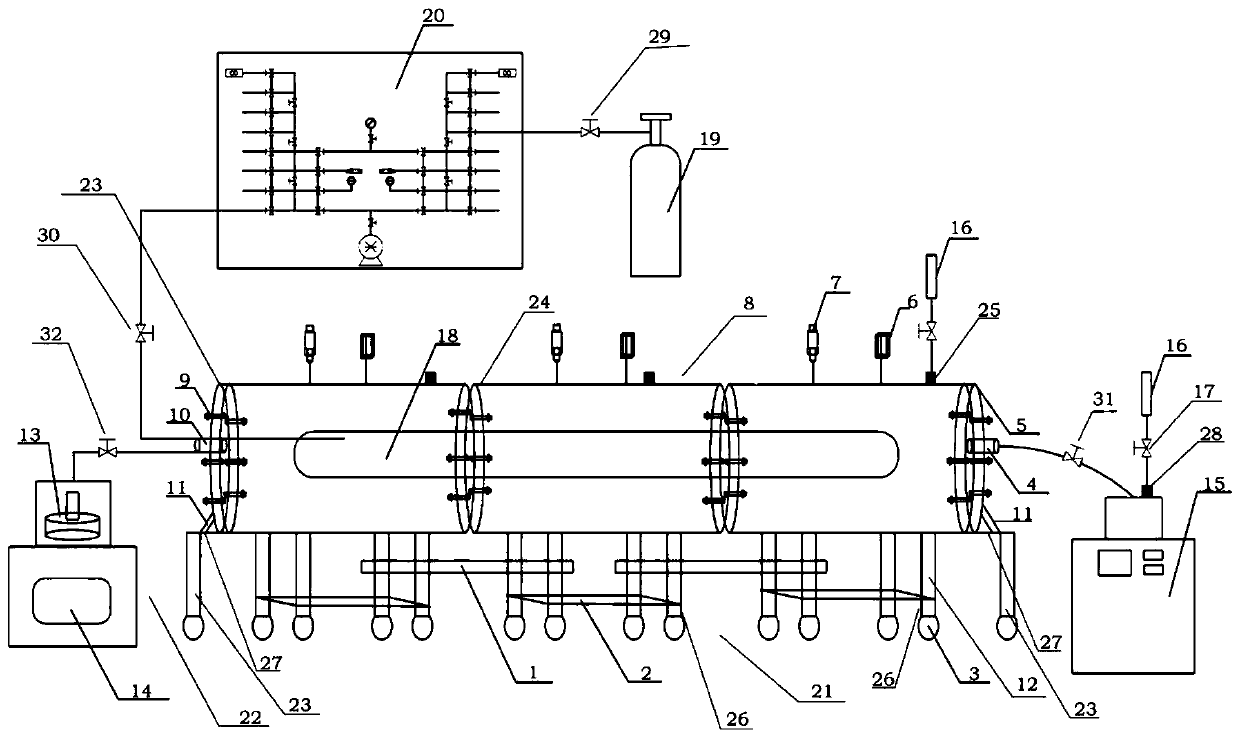

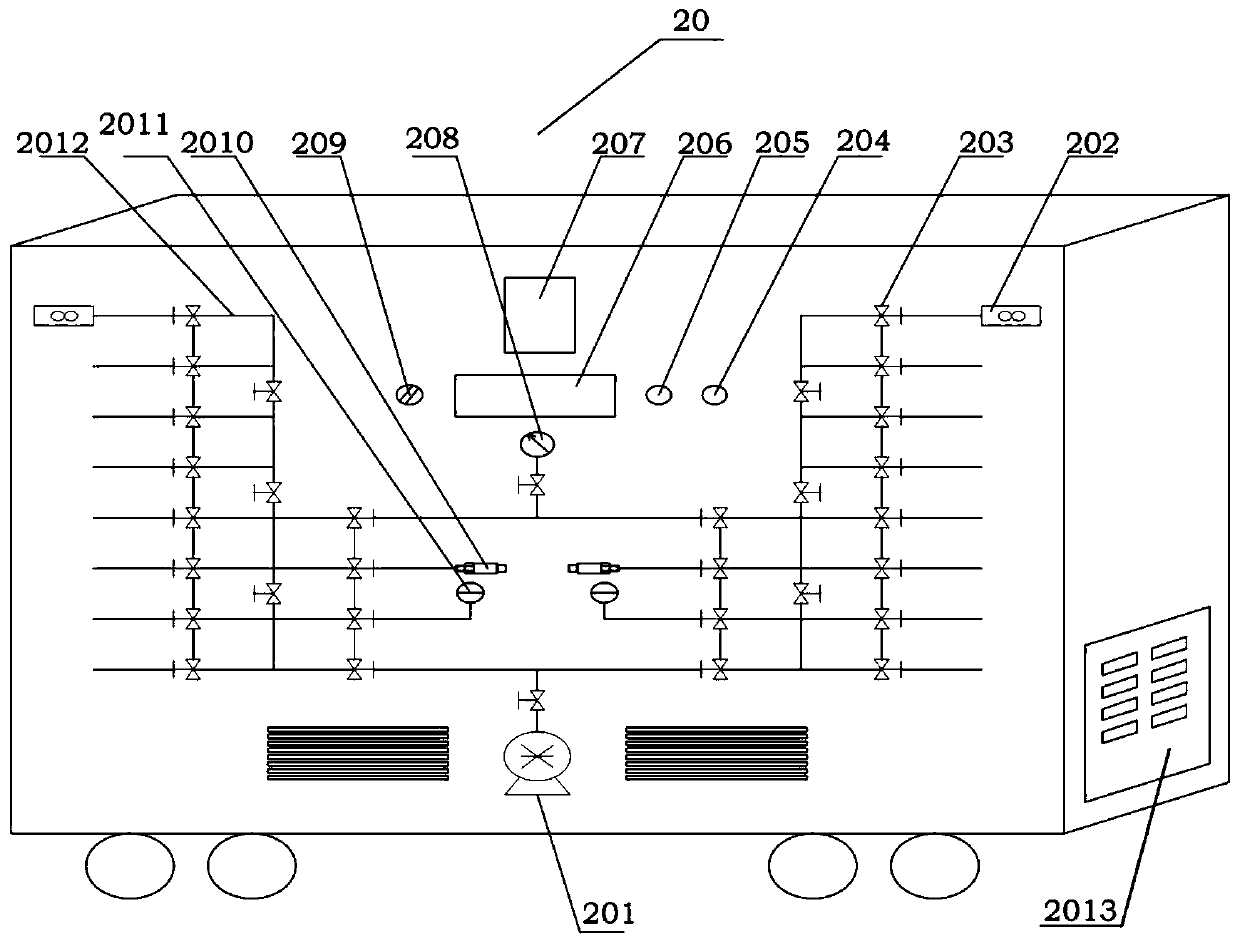

[0034] Such as figure 1As shown, this embodiment discloses a leak detection system for large container components, including a detection device 21 , a vacuum acquisition system 22 , a leak detector 15 , a pipe valve system 20 , a helium tank 19 , and a standard leak hole 16 . Wherein, during leak detection, the detection device is connected with the vacuum acquisition system and provides a vacuum for the detection device, and the leak detector used to catch helium leakage of the large container part is connected with the detection device, and the pipe valve system is connected with the large container part 18 and the detection device. Connection, the helium tank is connected with the pipe valve system, wherein the connection between the pipe valve system and the helium tank is mainly to provide helium for the large container parts, and the connection between the pipe valve system and the detection device is to discharge the pressure in the detection device to normal Press, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com