Pressurized water reactor nuclear power plant reactor core checking tool

A technology for nuclear power plants and pressurized water reactors, which is applied in the field of tools for nuclear power plant core verification for pressurized water reactors, can solve problems such as poor interface matching, increased operational risks, and connecting rods falling into the core, thereby increasing automatic The effect of identifying functions, improving inspection efficiency, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

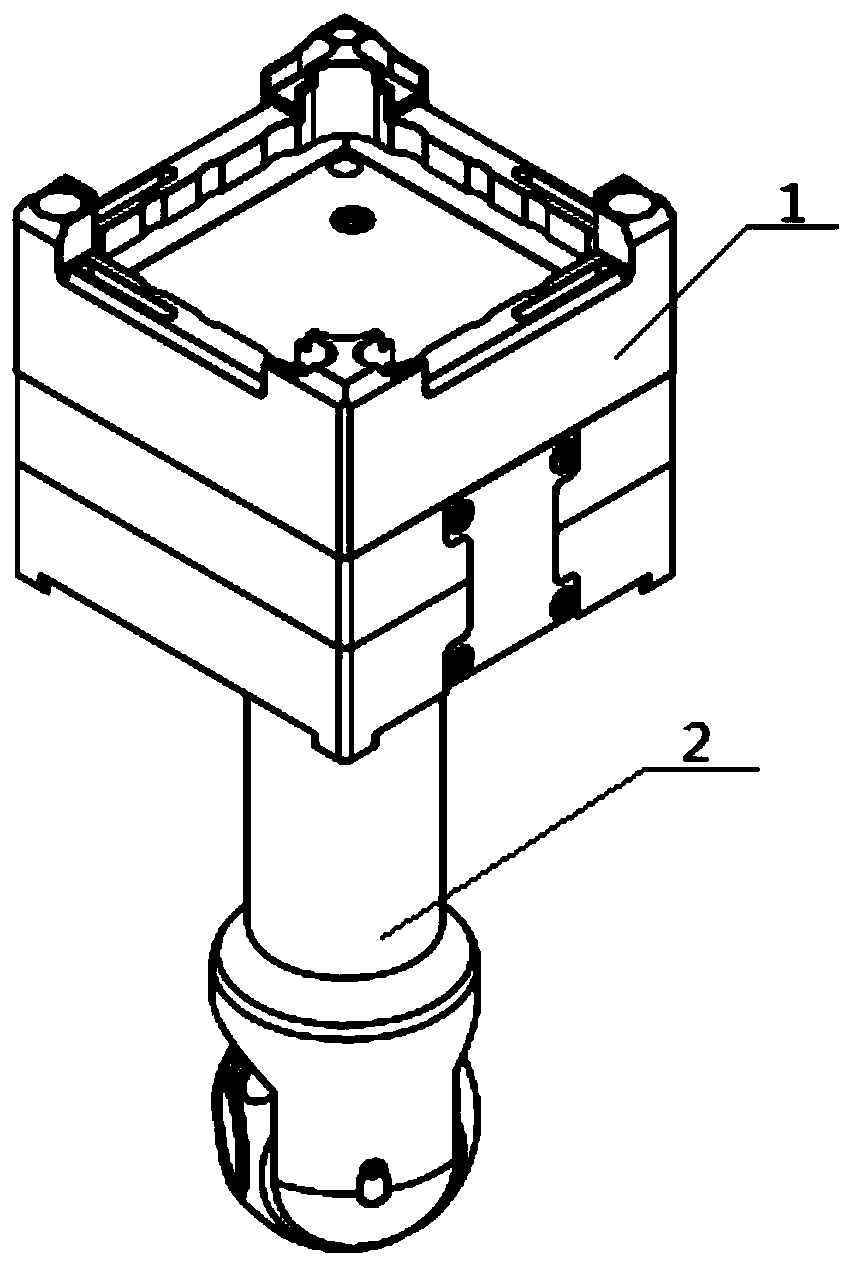

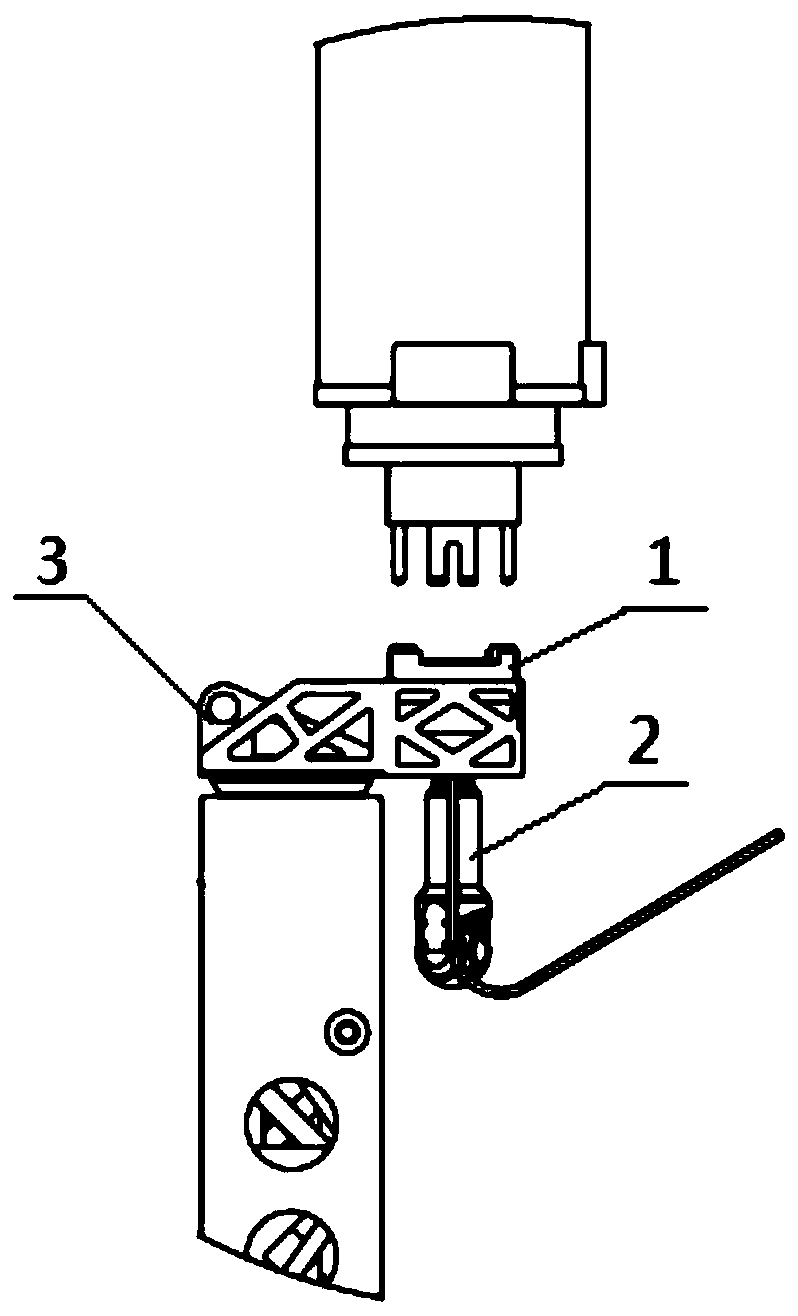

[0021] like figure 1 - As shown in -3, the tool for core inspection of the PWR nuclear power plant of the present invention includes an adapter 1, a radiation-resistant underwater camera 2, and a storage rack 3;

[0022] The adapter 1 is used to connect the radiation-resistant underwater camera 2 , one end of the adapter 1 is convenient for the loading and unloading machine to grab, and the other end is connected with the radiation-resistant underwater camera 2 .

[0023] The radiation-resistant underwater camera 2 is used to closely check information such as the fuel assembly identification number, and the image information is transmitted to the electrical cabinet located on the ground platform of the reactor building through a cable.

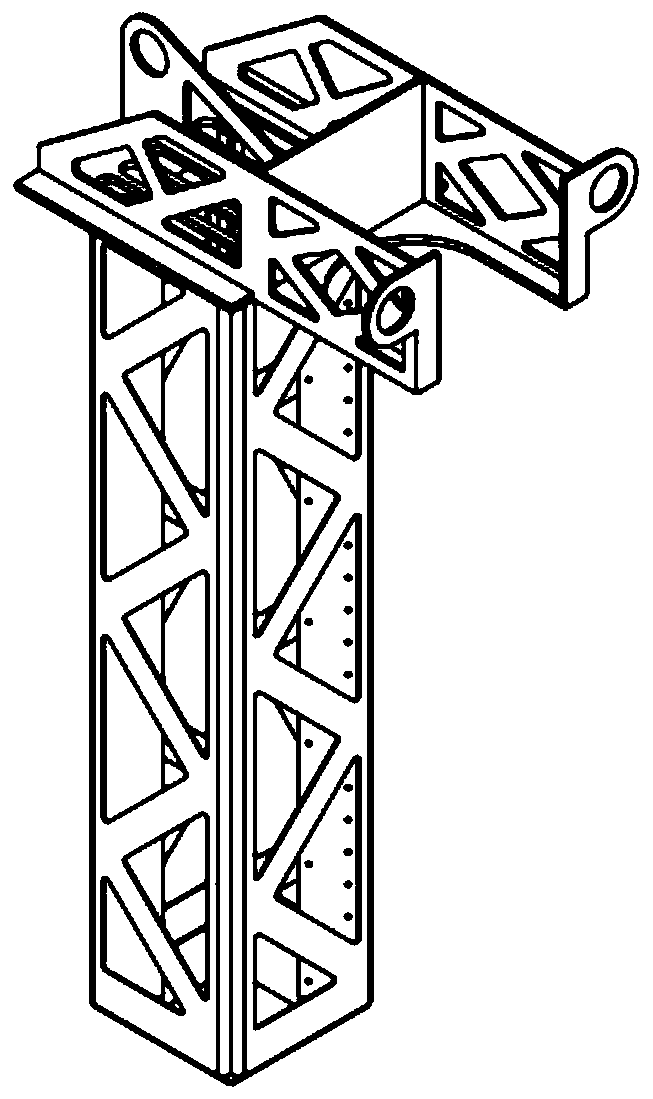

[0024] The storage rack 3 is used to temporarily store the radiation-resistant underwater camera 2 with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com