Piston pump, particularly high-pressure fuel pump for internal combustion engine

A technology of piston pump and internal combustion engine, which is applied in the direction of fuel injection pump, fuel injection device, pump, etc., can solve problems such as high cost, and achieve the effects of reducing component cost, small structure size, and simple manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

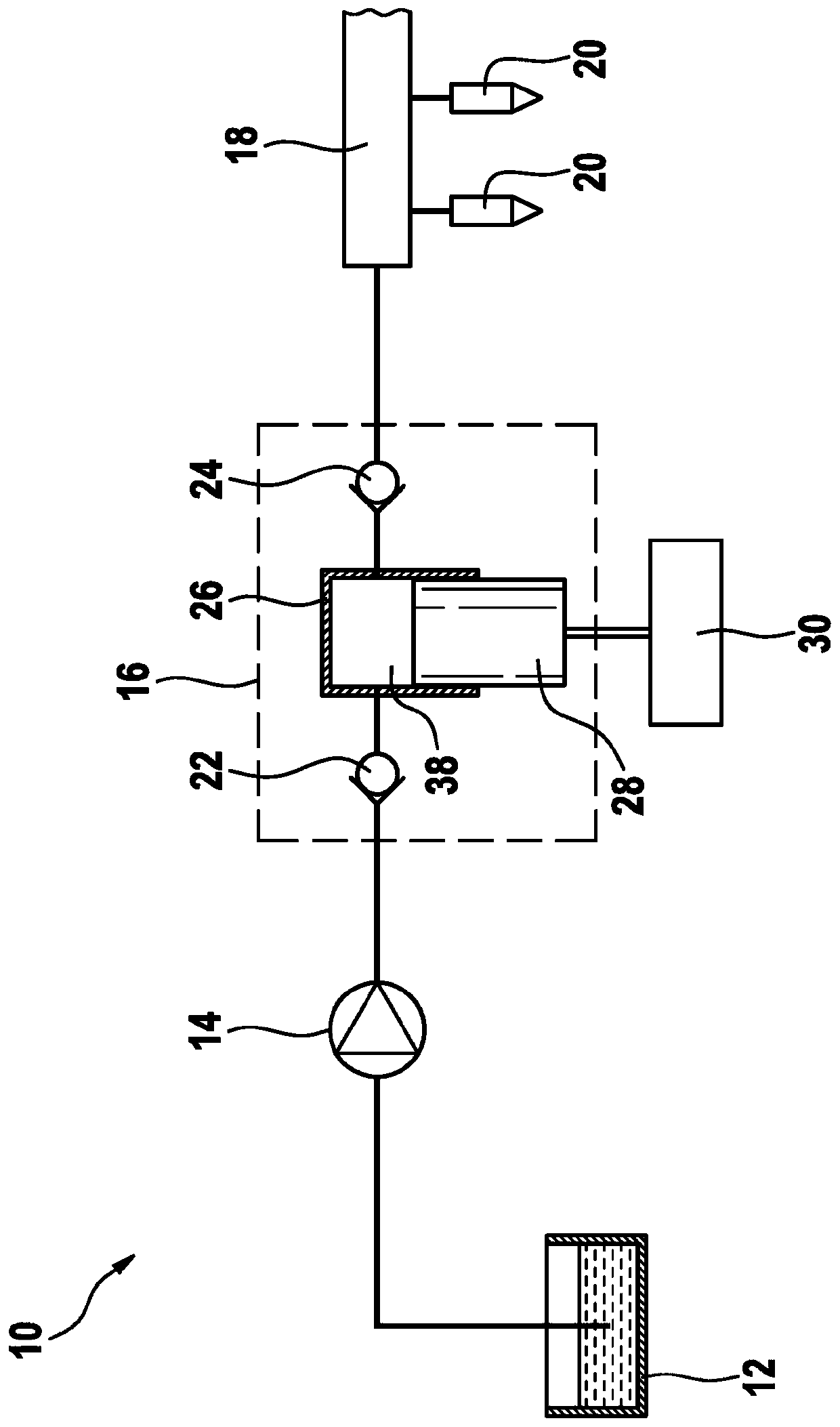

[0036] The fuel system of an internal combustion engine is figure 1 The middle bears the reference number 10 as a whole. The fuel system comprises a fuel container 12 from which an electric pre-delivery pump 14 delivers fuel to a high-pressure fuel pump designed as a piston pump 16 . The high-pressure fuel pump delivers fuel further to a high-pressure fuel rail 18 , to which a plurality of fuel injectors 20 are connected, which inject fuel into the combustion chambers of the internal combustion engine, not shown.

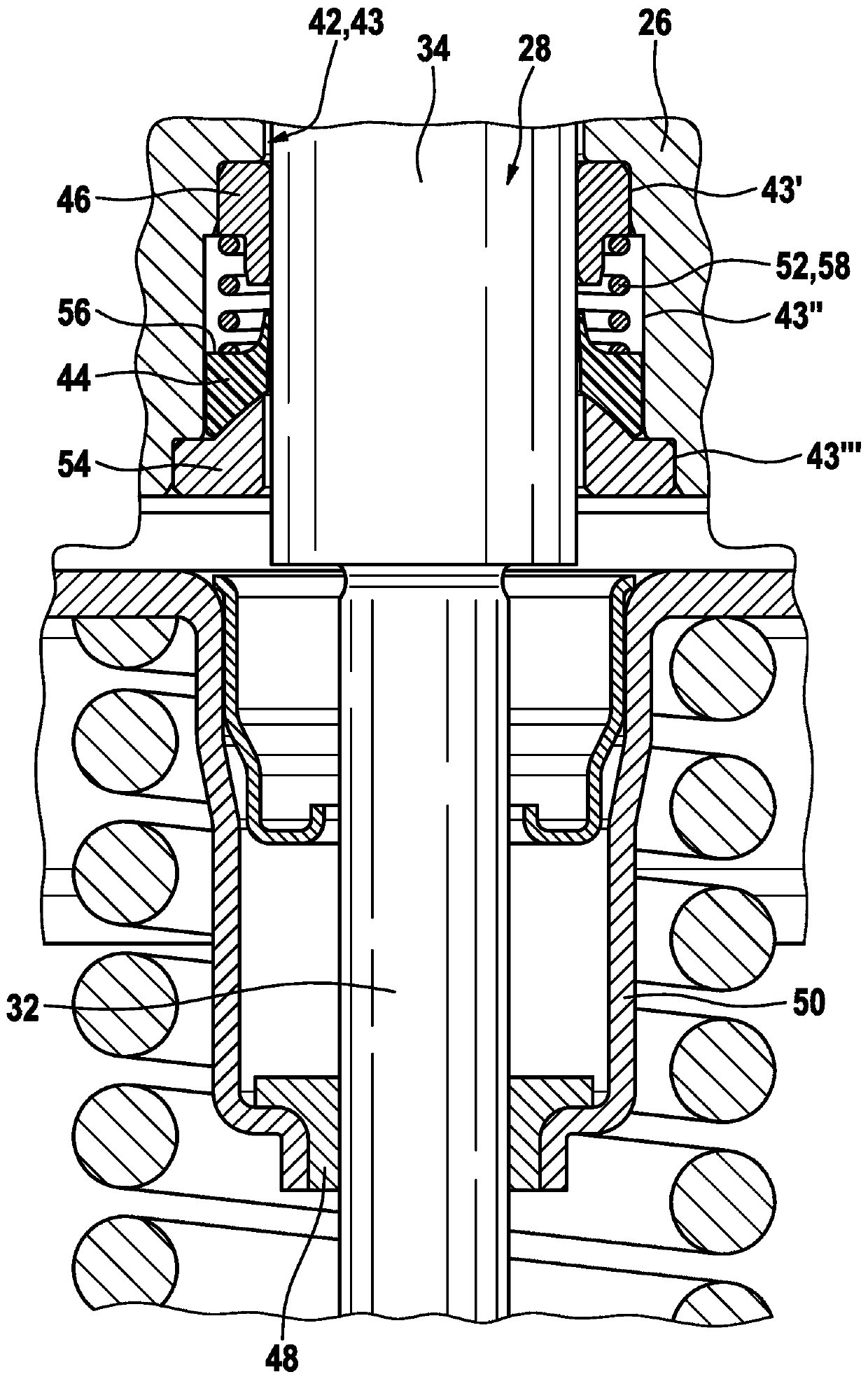

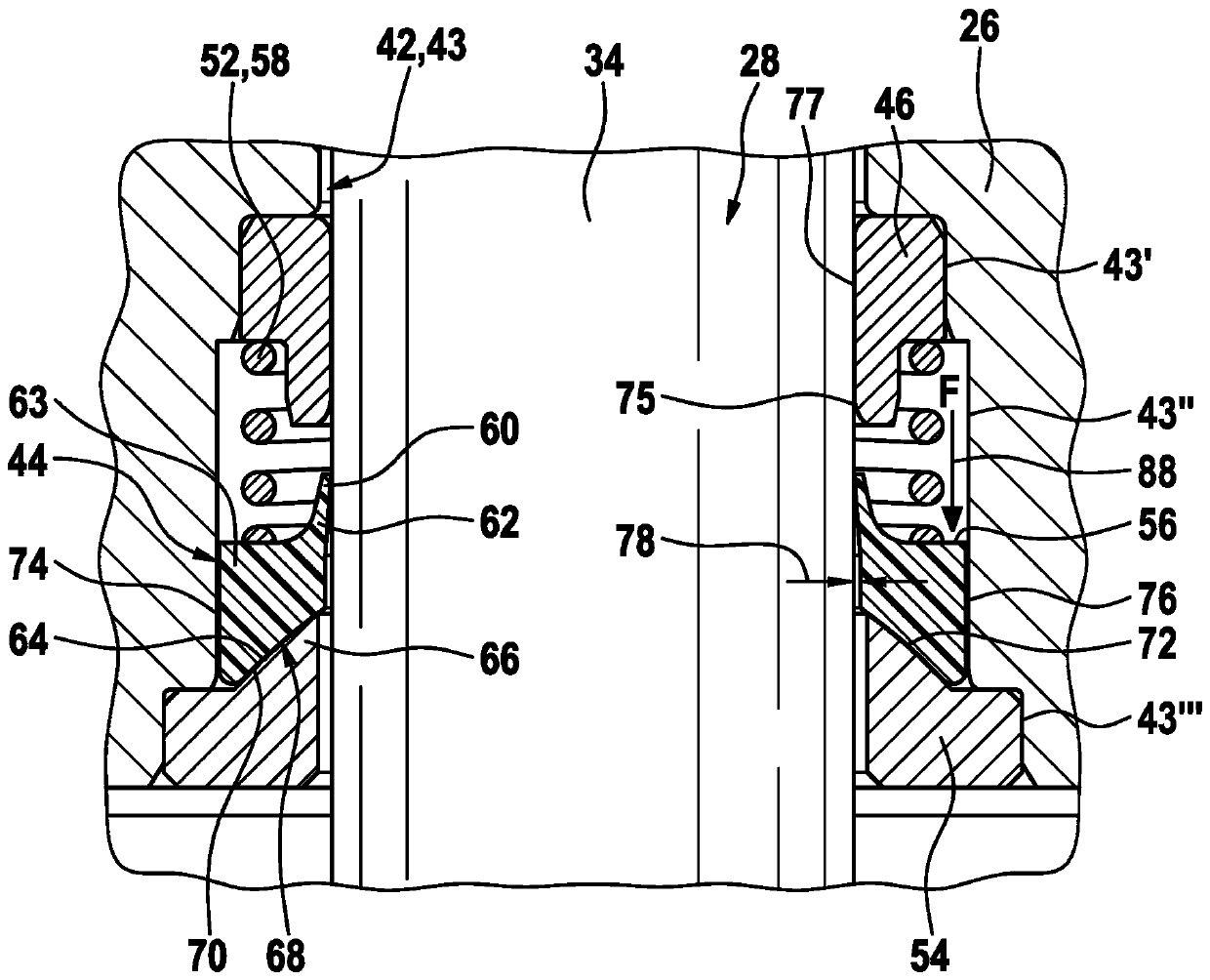

[0037] The piston pump 16 includes an inlet valve 22 , an outlet valve 24 and a pump housing 26 . A pump piston 28 is received in the pump housing so as to be movable back and forth. The pump piston 28 is set in motion by a drive 30, wherein the drive 30 figure 1 is shown schematically only. The drive 30 can be, for example, a camshaft or an eccentric shaft. The inlet valve 22 is designed as a flow control valve by means of which the fuel quantity delivered by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com