Ceramic raw material suspension granulation device

A technology of granulation equipment and ceramic raw materials, which is applied in the field of ceramic raw material suspension granulation equipment, and can solve the problems of unreasonable distribution of powder particles, poor fluidity, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

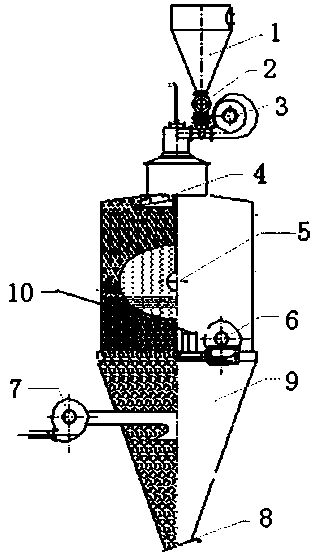

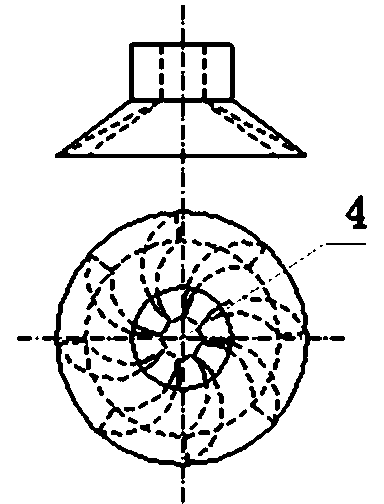

[0019] like figure 1 As shown, a ceramic raw material suspension granulation equipment includes a feeding device and a granulation suspension tower, wherein the feeding device includes a linear compensation hopper 1 and an impeller feeder 2, and the powder passes through the impeller feeder 2. The feed material enters the powder disperser 4, atomized and dispersed into the granulation suspension tower 9 under the action of the powder disperser 4. The upper part of the granulation suspension tower 9 is a cylinder, and the lower part is a cone structure. The inside of the tower 9 is provided with an air guide groove 10 and a high-pressure atomizing nozzle 5, and a high-pressure suspension fan 6 and a dust exhaust fan 7 are arranged outside the granulation suspension tower 9. The lower part of the cone of the granulation suspension tower 9 has a sealed outlet Mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com