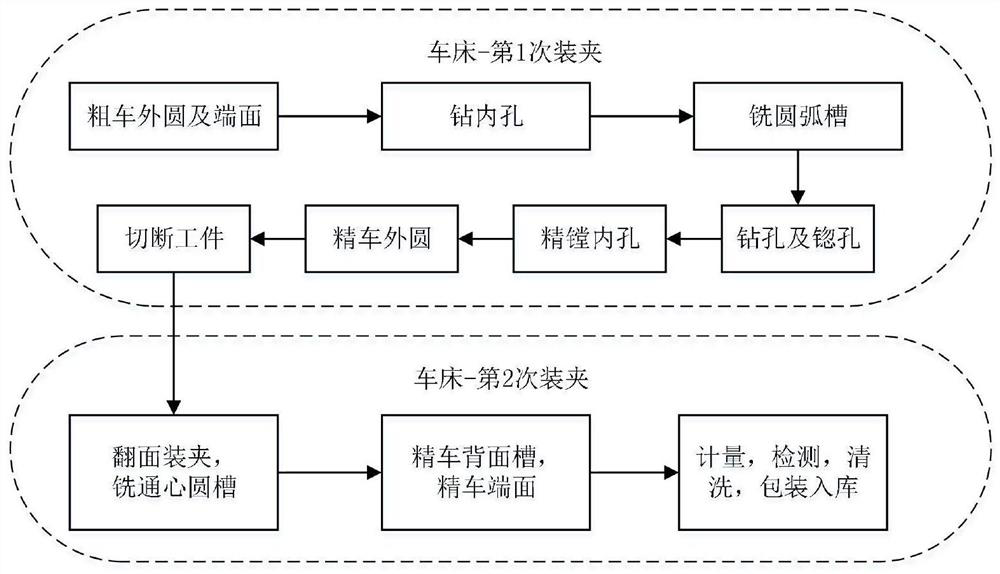

A method for turning and milling compound processing of gyroscope wire guard

A process method and composite processing technology, applied in the field of mechanical processing, can solve the problems of reducing the processing accuracy and quality of parts, long auxiliary processing time for wire guard processing, and no published patent documents have been found, so as to reduce processing difficulty and shorten processing time. Auxiliary time, effect of shortening auxiliary processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings; the present embodiments are descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

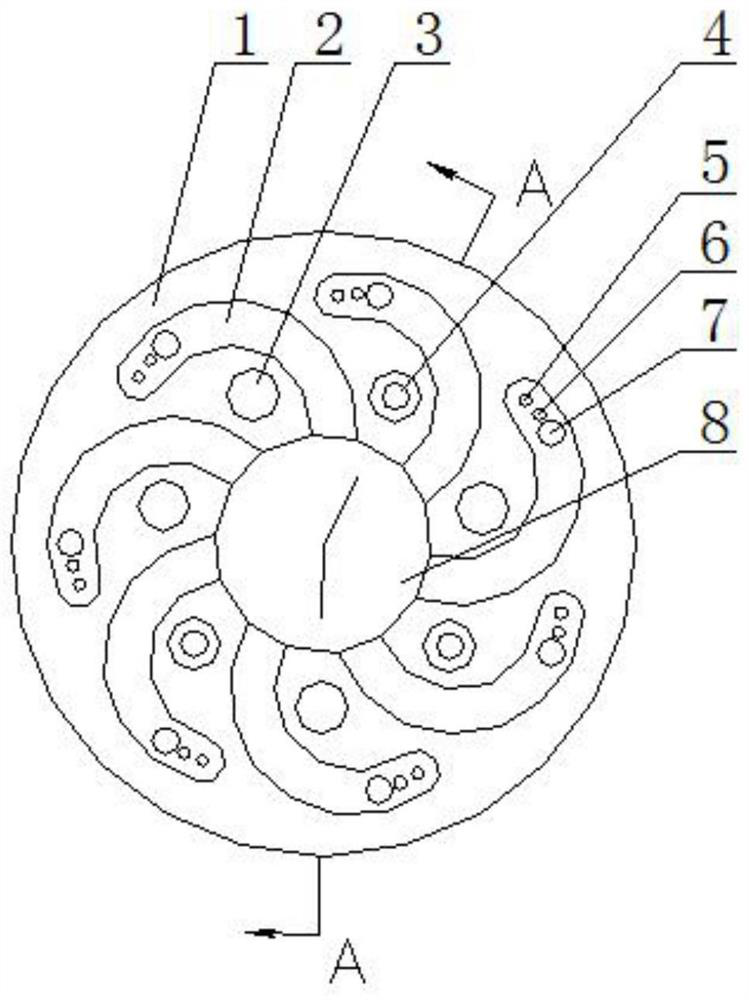

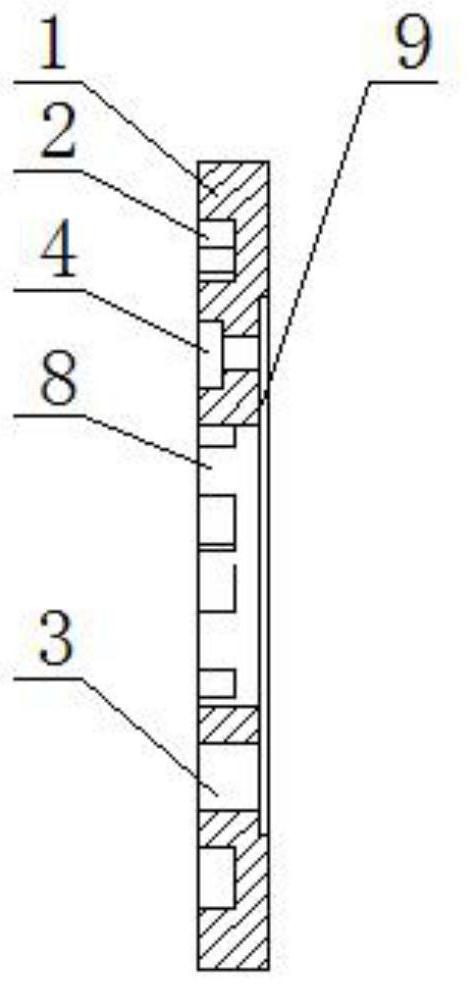

[0044] First describe the structure of the gyroscope wire guard of the present invention, see figure 2 , 3 , 4, 5, 6.

[0045] The gyroscope wire guard 1 is a disc-shaped structure, and its front structure is as follows: a central inner hole 8 is formed in the center of the disc. There are seven identical arc grooves 2, and the inner top of the arc groove is closed by an arc, and the bottom of the arc groove at the closed part of the arc is respectively made with φ0.8mm I through hole 5 and II through hole from inside to outside. The hole 6 and the through hole 7 of φ1.8mm are formed with three stepped holes 4 of φ3.5-φ1.8mm with the same diameter between the spaced arc grooves, and are formed between the rema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com