Solid tyre blank sorting system

A sorting system and solid tire technology, applied in the direction of sorting, tires, and other household appliances, can solve the problems of not significantly reducing the labor intensity, the underlying solid tires are under high pressure, and the line body only has a sorting function. Save labor costs, high degree of automation, and avoid extrusion deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0051] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of the structure, change of the proportional relationship or adjustment of the size shall fall within the range covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. within range.

[0052]At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invent...

Embodiment

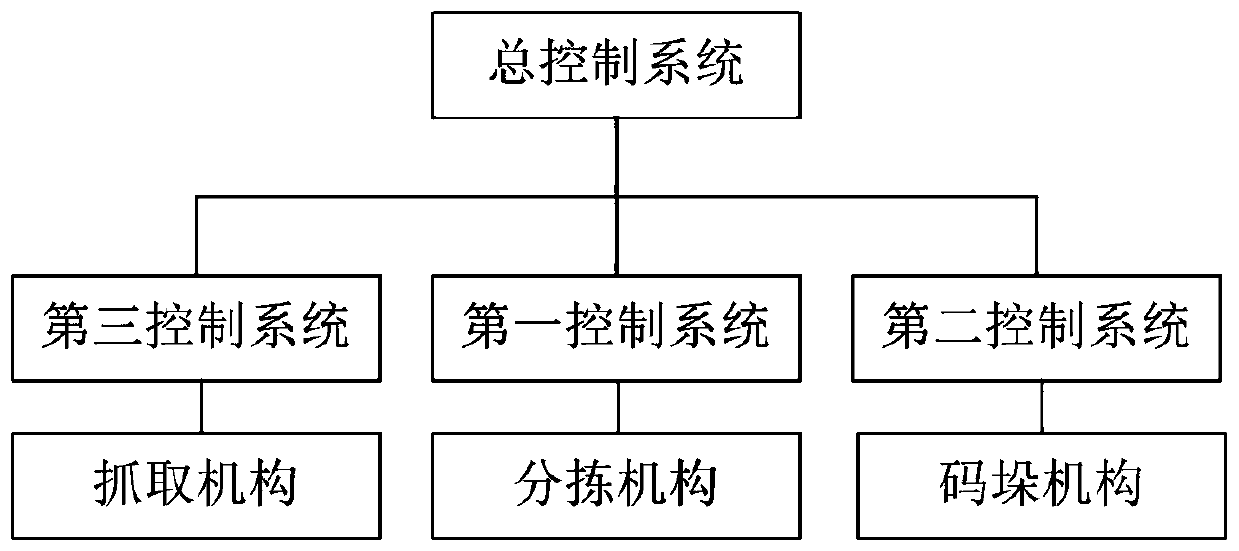

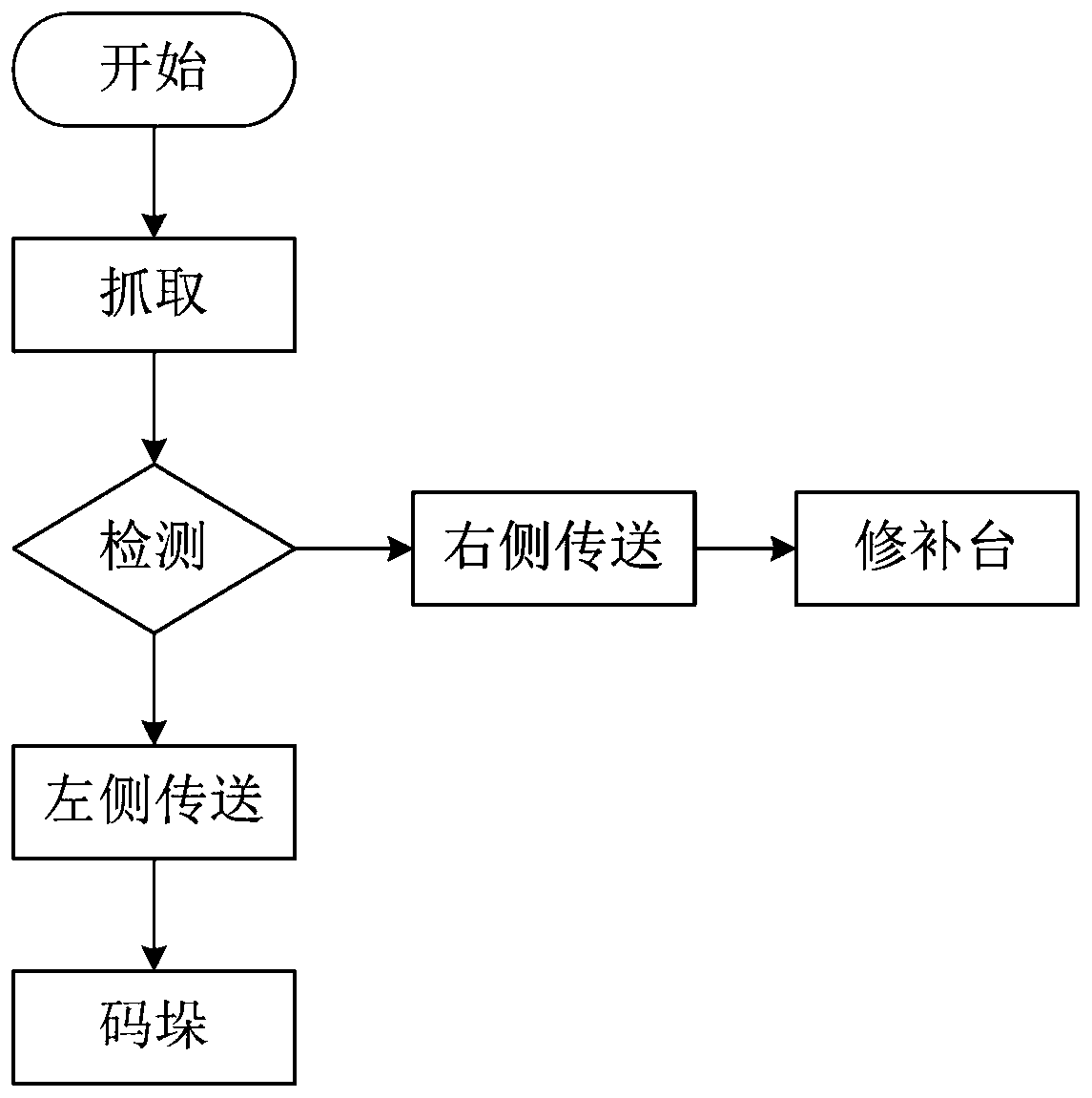

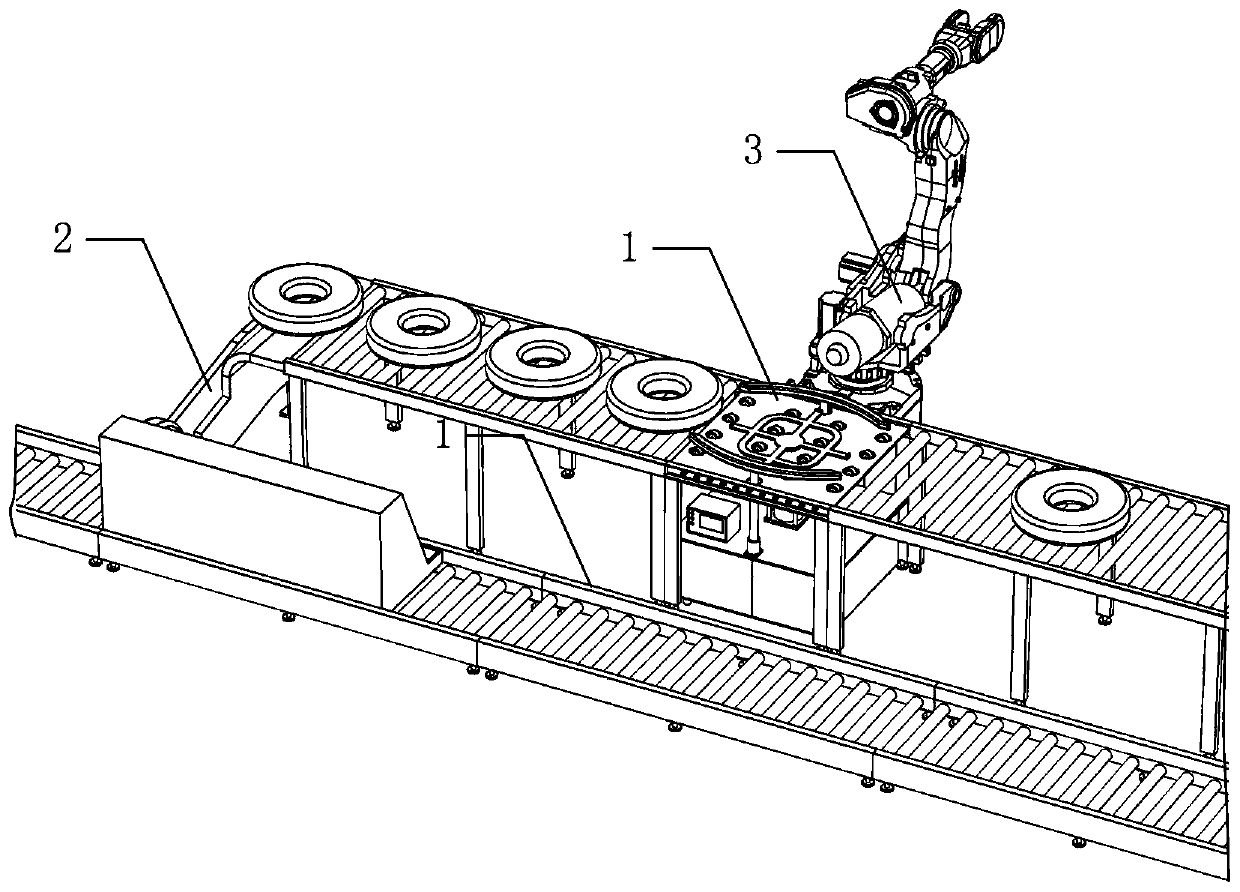

[0054] combined with Figure 1-11 , a sorting system for solid embryos, including a general control system, a grabbing mechanism 3, a sorting mechanism 1 and a palletizing mechanism 2;

[0055] The gripping mechanism 3 includes a manipulator controlled by a third control system;

[0056] The sorting mechanism 1 includes a detection platform 11 and a delivery platform 12 controlled by the first control system 13; the detection platform 11 includes a table top 111 fixed on a platform 1111, and the table top 111 is provided with roller holes for fixing rollers 112 1112; the central position of the table top 111 is provided with a plate hole 1113 for the gravity induction plate 113 to pass through; the gravity induction plate 113 includes a tray 1131 with a gravity sensor 1133 and a liftable column 1132 that passes through the plate hole 1113 at the bottom of the tray 1131, The other end of the column 1132 is connected to the cylinder 115; in the detection state, the column 1132 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com