A wall-climbing robot system for hull paint removal

A wall-climbing robot and robot technology, which is applied to ship hulls, ship construction, ship cleaning devices, etc., can solve problems such as low efficiency and operators cannot work for a long time, and achieve the effects of improving efficiency, reducing load and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

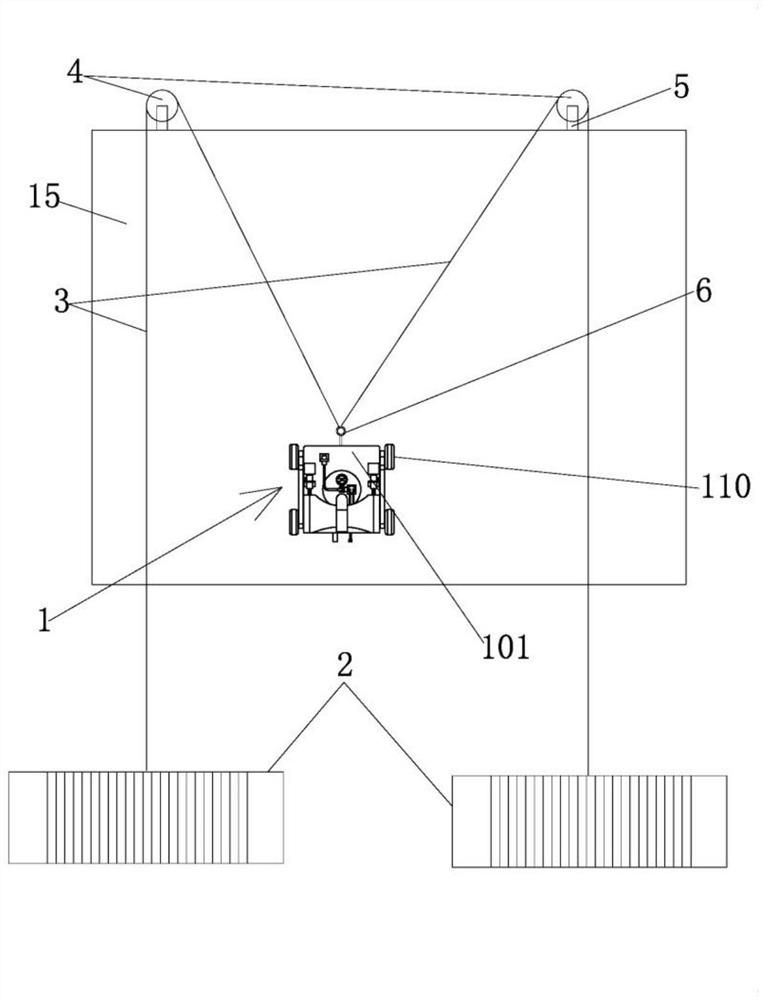

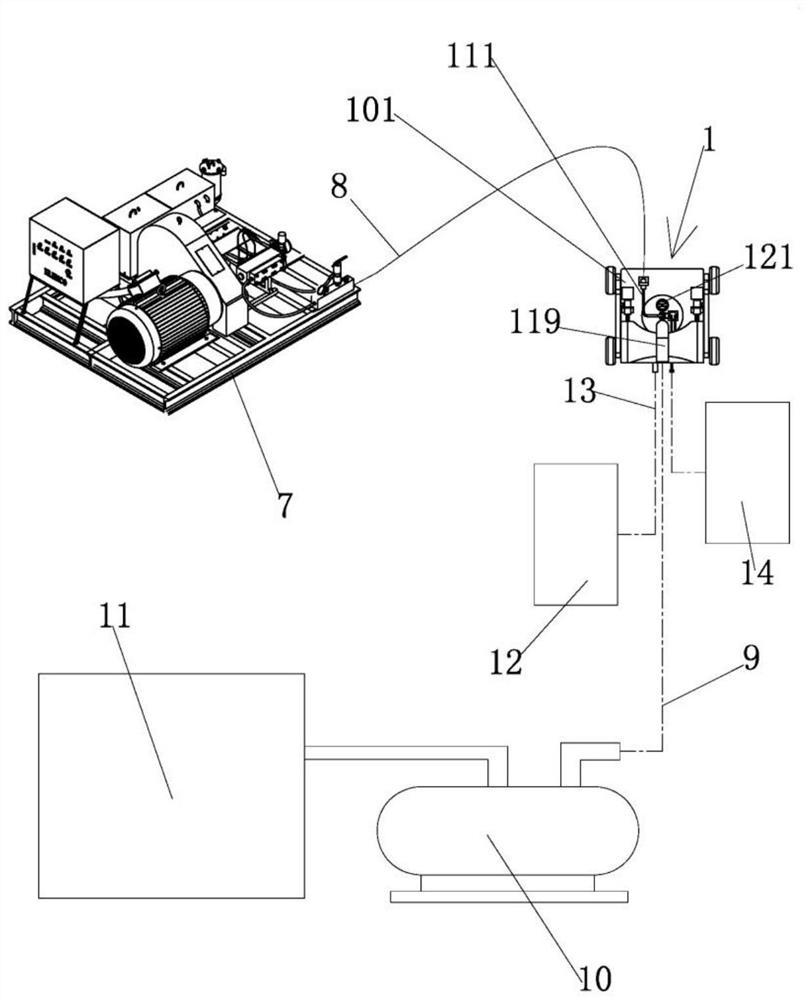

[0032] Attached below Figure 1-6 The present invention is further illustrated with specific examples.

[0033] Such as Figure 1-6 As shown, a hull wall-climbing robot system for paint removal includes a robot main body 1 that automatically crawls on the hull wall 15 under remote control, and a lifting component that hangs the robot main body 1 .

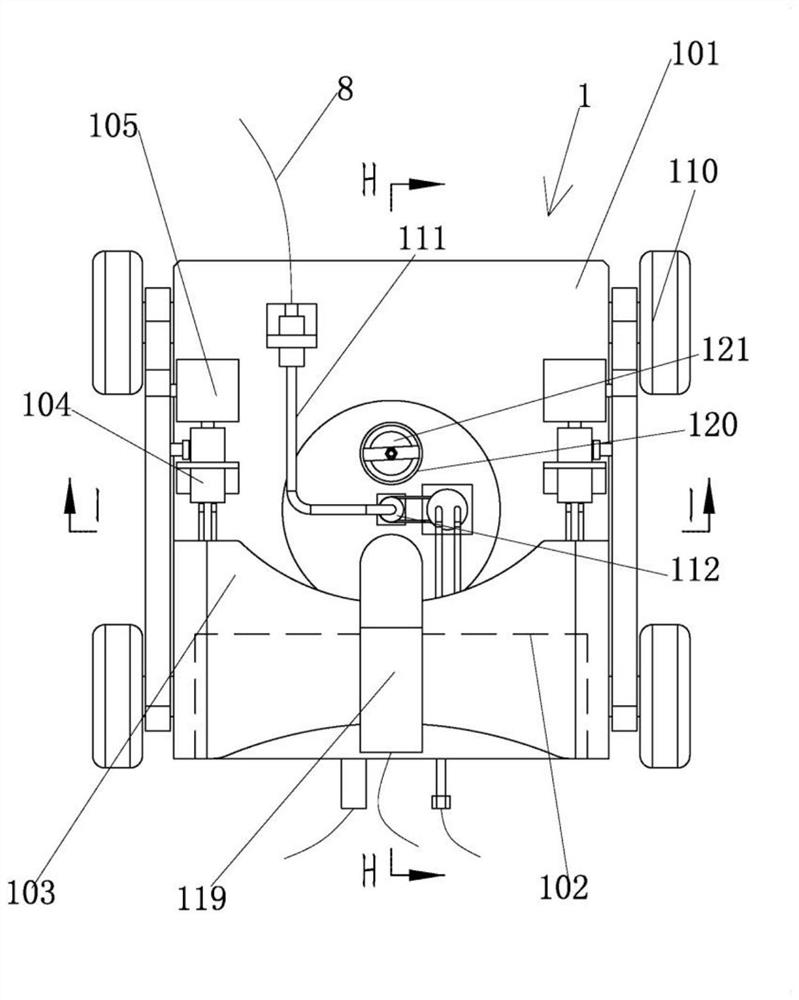

[0034] Above-mentioned robot main body 1 comprises:

[0035] Robot Framework 101;

[0036] Two pairs of walking wheels 110 respectively rotate and are arranged on the left and right sides of the robot frame 101;

[0037] The walking driving mechanism installed on the robot frame 101 is used to drive two pairs of walking wheels 110 to roll on the hull wall 15;

[0038] The spray washing mechanism installed on the robot frame 101 is used to wash away the old paint on the hull wall 15; and

[0039] A sewage recycling mechanism for recycling sewage arranged on the robot frame 101 .

[0040] Wherein, the sewage discharge end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com