Anti-seepage plugging admixture for well cementation, and anti-seepage plugging cement paste

A technology of external admixture and cement slurry, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as insufficient solution of leakage problems, hidden dangers, influence on construction safety, etc., so as to reduce apparent permeability, Outstanding plugging effect and good plugging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

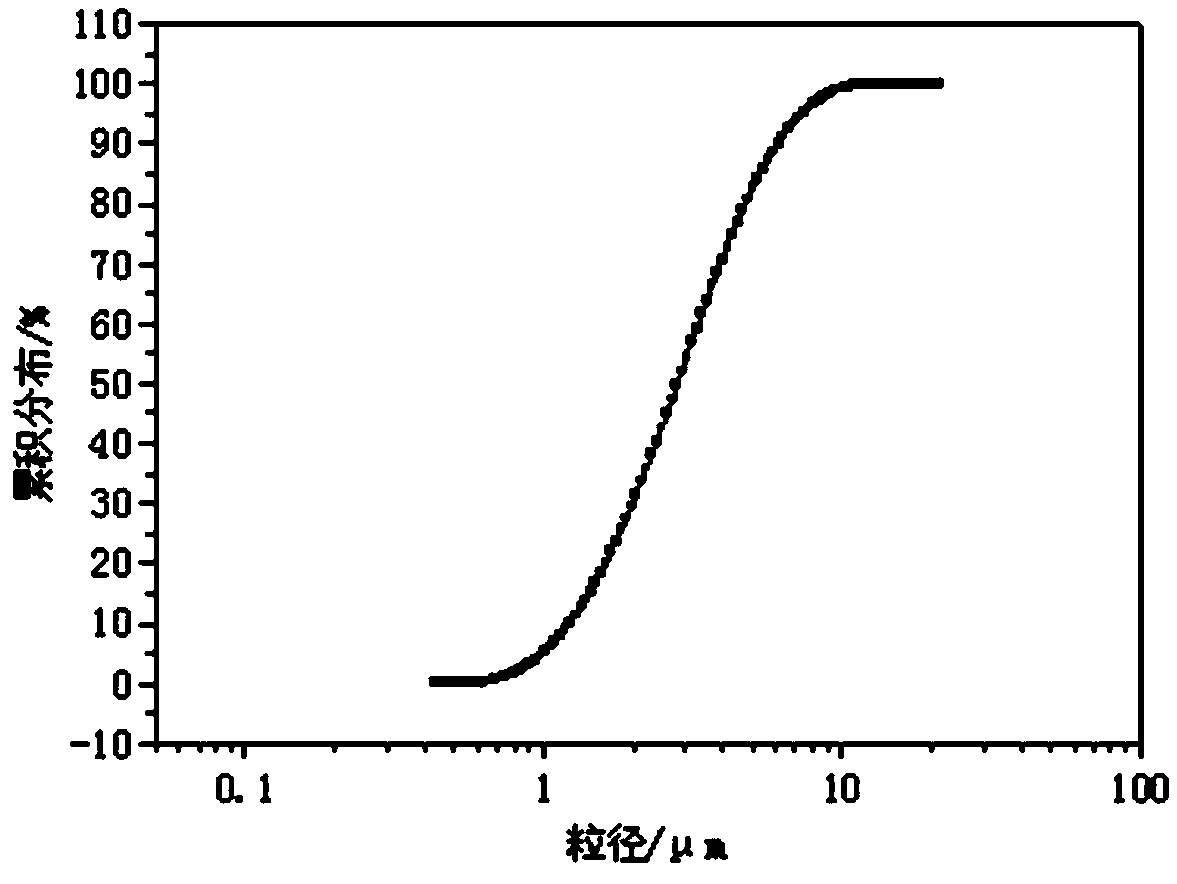

[0049] An anti-seepage and plugging external admixture for well cementing, see Table 1 for each component and its weight. In the silicon carbide used therein, the sum of the particle volumes with a particle diameter of 1-10 μm accounts for more than 90% of the total volume of the silicon carbide.

[0050] According to the ratio in Table 1, the inorganic hard particle silicon carbide and the organic soft particle styrene-butadiene copolymer are fully mixed in proportion to obtain the anti-seepage and plugging external admixture for well cementing. For the particle size distribution curve of the anti-seepage plugging external admixture for well cementing, please refer to figure 1 .

[0051] The composition and the weight of the anti-seepage plugging external admixture for well cementing of table 1 embodiment 1

[0052] type Component parts by weight Inorganic hard particles Silicon carbide 5.0 Organic soft particles Styrene-butadiene copolymer 1.0...

Embodiment 2

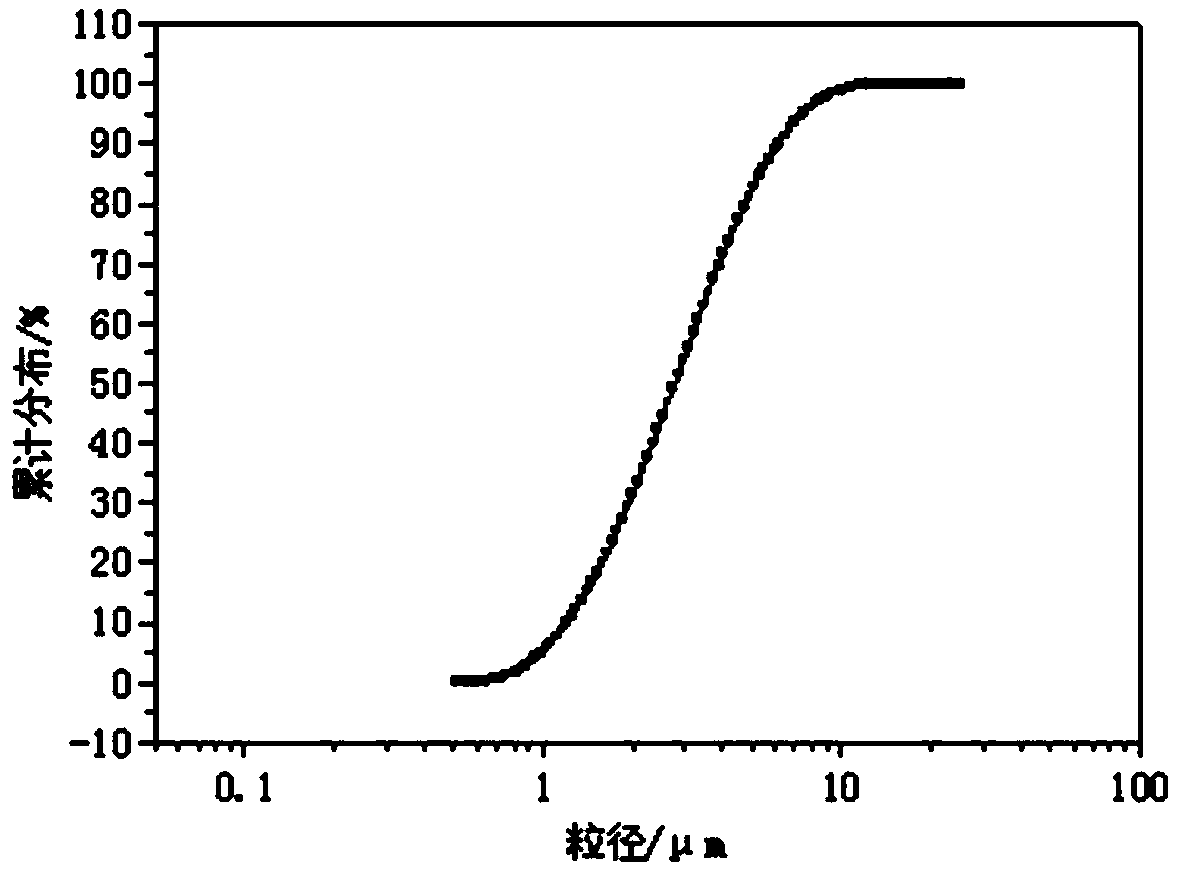

[0054] An anti-seepage and plugging external admixture for well cementing, see Table 2 for each component and its weight. Among them, in silicon carbide and titanium dioxide, the sum of the particle volumes with a particle diameter of 1-10 μm accounts for more than 90% of the sum of the volumes of silicon carbide and titanium dioxide.

[0055] The composition and the weight of the anti-seepage plugging external admixture of table 2 embodiment 2

[0056]

[0057] According to the ratio in Table 2, the above two kinds of inorganic hard particles and two kinds of organic soft particles are fully mixed and evenly mixed according to their respective proportions, and the anti-seepage and plugging external admixture for well cementing is obtained. For the particle size distribution curve of the anti-seepage plugging external admixture for well cementing, please refer to figure 2 .

Embodiment 3

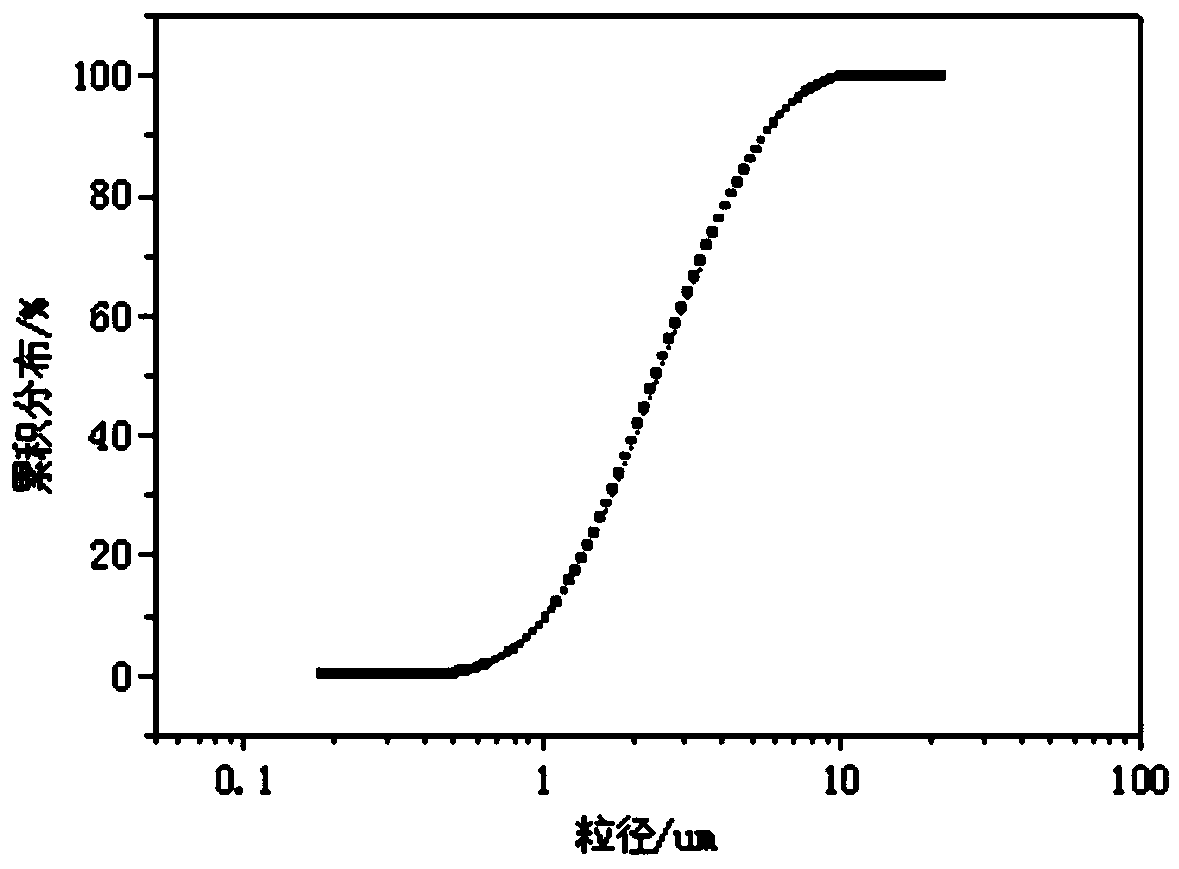

[0059] An anti-seepage and plugging external admixture for well cementing, see Table 3 for each component and its weight. Among silicon carbide, titanium dioxide, zirconium dioxide and diatomaceous earth, the sum of the particle volumes with a particle diameter of 1-10 μm accounts for more than 90% of the total volume of all hard particles.

[0060] The composition and the weight of the anti-seepage plugging external admixture of table 3 embodiment 3

[0061]

[0062]

[0063] According to the proportions in Table 3, the above four kinds of inorganic hard particles and three kinds of organic soft particles are fully mixed and evenly mixed according to their respective proportions, and the anti-seepage and plugging external admixture for well cementing is obtained. For the particle size distribution curve of the anti-seepage plugging external admixture for well cementing, please refer to image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com