Styrene-acrylic latex for oil field cementing and its preparation and application

A styrene-acrylic latex and cementing technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as strong sensitivity, difficult on-site adjustment, and complex synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

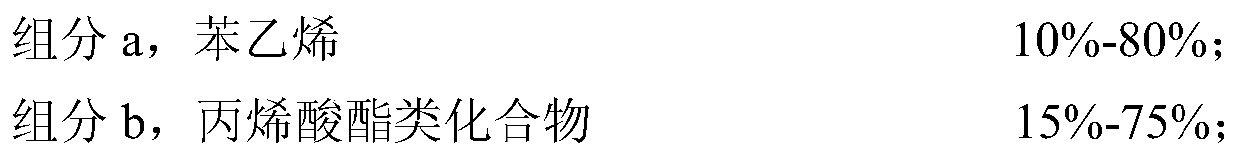

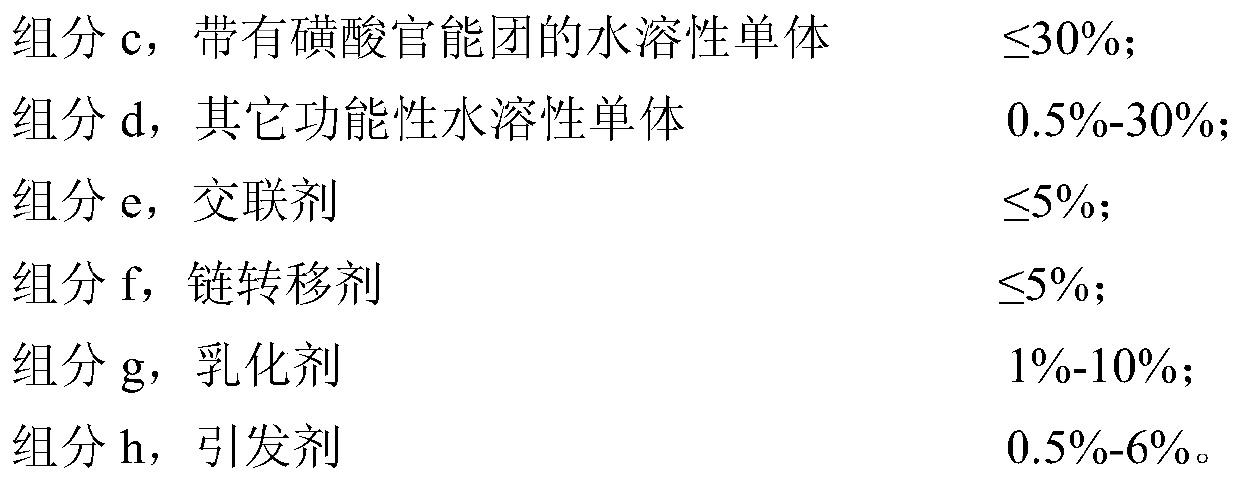

[0048] The second aspect of the present invention relates to a kind of preparation method of styrene-acrylic latex as described in the first aspect of the present invention, comprising:

[0049] Step A, mixing at least one of components a, b, d, g and h and optional components c, e and f with water, and then emulsifying by a shear emulsification pump to prepare a monomer pre-emulsion ;

[0050] Step B, mixing the initiator with water to prepare an initiator solution;

[0051] Step C, reacting 5%-10% (mass) monomer pre-emulsion with 5%-10% (mass) initiator solution to prepare emulsion seeds;

[0052] Step D, adding dropwise the remaining monomer pre-emulsion and the remaining initiator solution to the emulsion seed to react to prepare a reaction mixture;

[0053] In step E, add a redox initiator dropwise to the reaction mixture, and then add a pH regulator after the dropwise addition is completed, to obtain styrene-acrylic latex.

[0054] The term "water" used in the present...

Embodiment 1

[0085] Add 900kg deionized water, 20kg alkylphenol polyoxyethylene (10) ether, 500kg styrene, 800kg butyl acrylate, 12kg divinylbenzene, 60kg acrylamide, 50kg AMPS in the stirred reactor (raw material tank) (2-acrylamide-2-methylpropanesulfonic acid), pre-emulsified for half an hour for later use. Add sodium persulfate 11kg in another raw material dropping tank simultaneously, deionized water 1100kg, drop components as initiator.

[0086] Put 700kg of deionized water into the reactor, raise the temperature to 90°C, add 5% of the above-mentioned pre-emulsion, 10% of the above-mentioned initiator solution, and after 20 to 30 minutes of reaction, start to drop the remaining pre-emulsion and initiator solution at the same time , the dropping process continued for 4 hours. After dripping, keep warm for 30 minutes, lower the temperature to 85°C, add dropwise solution A consisting of 4.2kg tert-butyl hydroperoxide and 200kg water, solution B consisting of 2.5kg sodium thiosulfate an...

Embodiment 2

[0088] Add 900kg deionized water in the reactor (raw material tank) with stirring, 30kg myristylphenol polyether sulfosuccinic acid monoester sodium salt, 20kg alkylphenol polyoxyethylene (10) ether, 700kg styrene, 600kg butyl acrylate, 60kg acrylamide, pre-emulsified for half an hour for use. Add 11kg of sodium persulfate and 1100kg of deionized water in the raw material dropping tank at the same time, and add components dropwise as the initiator.

[0089]Put 700kg of deionized water into the reactor, raise the temperature to 90°C, add 5% of the above-mentioned pre-emulsion, 10% of the above-mentioned initiator solution, and after 20 to 30 minutes of reaction, start to drop the remaining pre-emulsion and initiator solution at the same time , the dropping process continued for 4 hours. After dripping, keep warm for 30 minutes, lower the temperature to 85°C, add dropwise solution A consisting of 4.2kg tert-butyl hydroperoxide and 200kg water, solution B consisting of 2.5kg sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com