Shield tail grouting liquid mixing valve

A grouting and liquid mixing technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of complex structure and inconvenient construction operation, and achieve the effect of simplifying steps and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

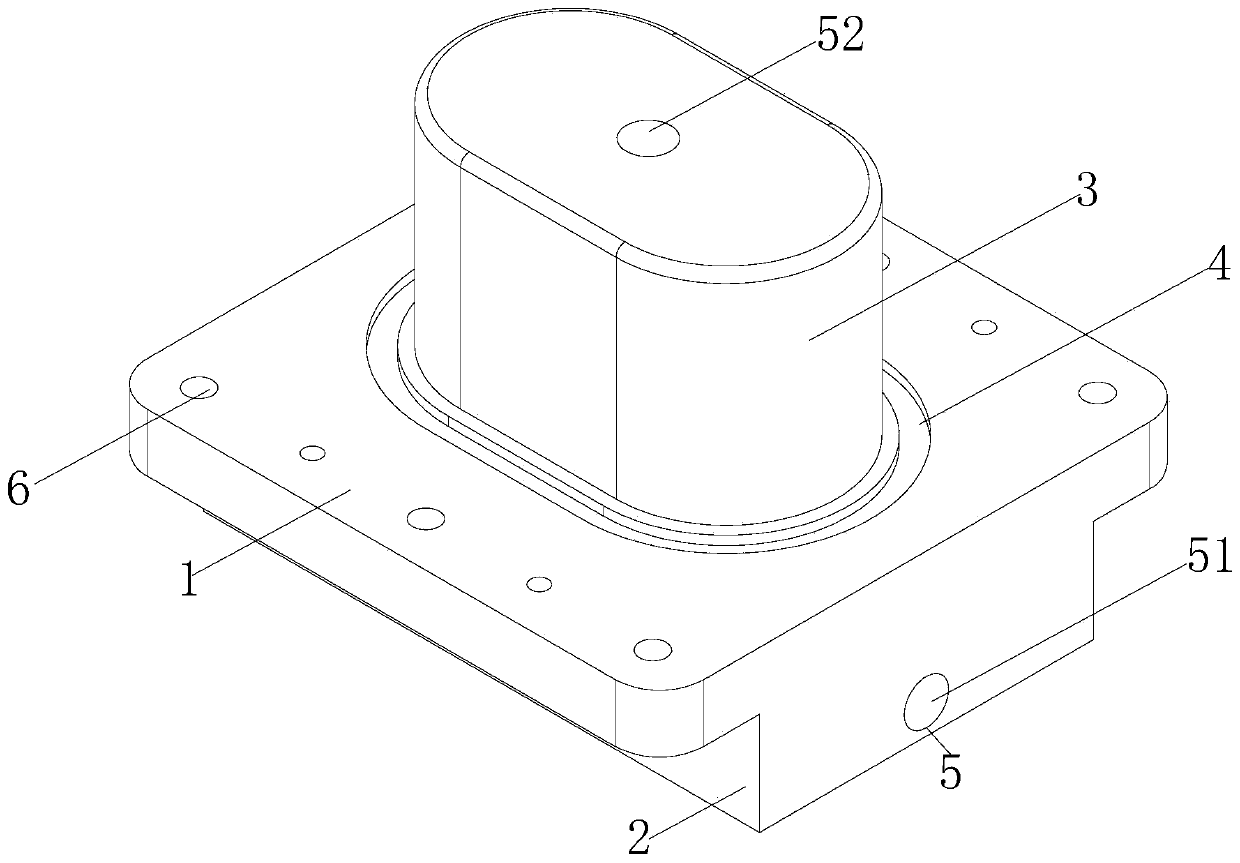

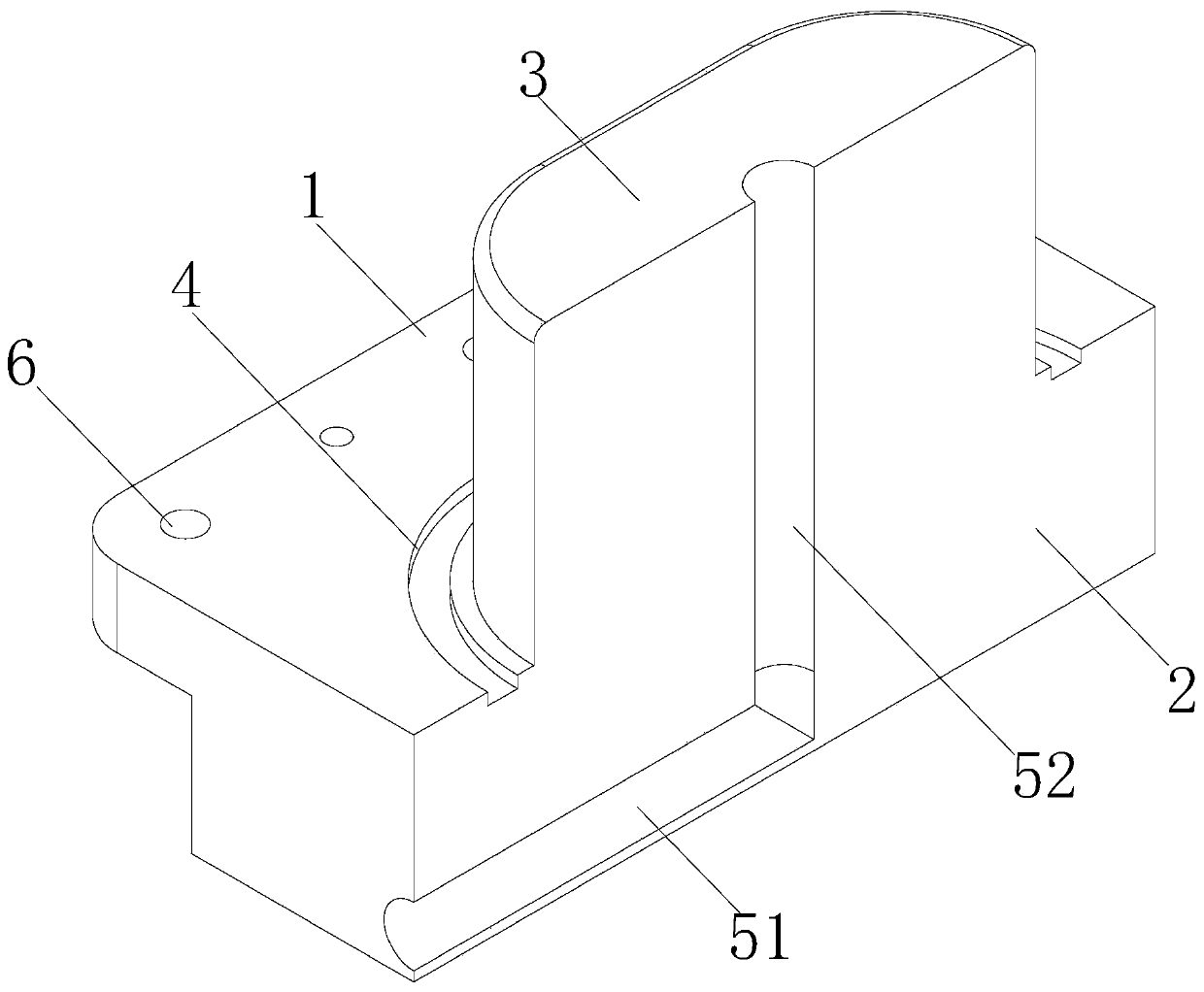

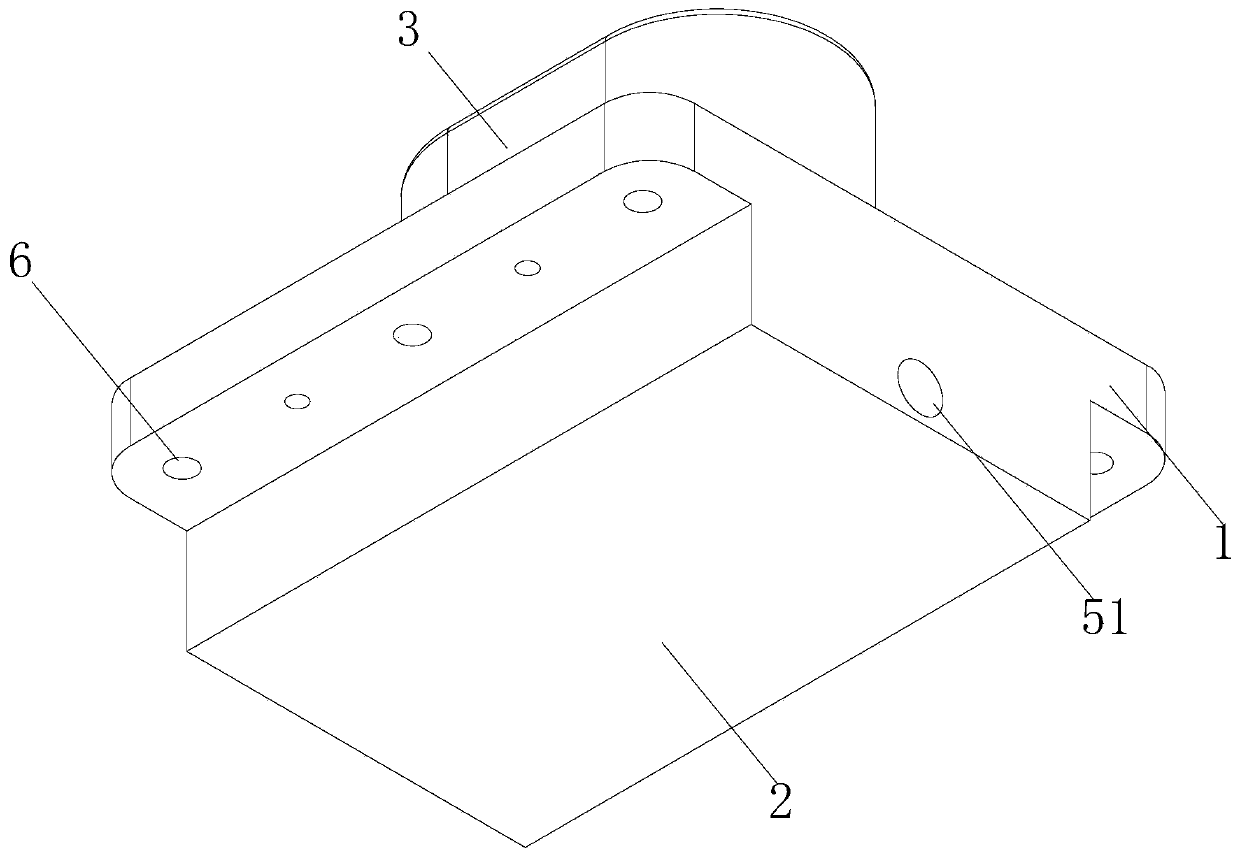

[0019] see Figure 1-3 , the present invention provides the following technical solutions: a shield tail grouting mixed liquid valve, including a mounting block 1, the bottom of the mounting block 1 is fixedly installed with a protruding block 2, the thickness of the protruding block 2 is 23cm, and the bottom of the mounting block 1 is fixed There is an embedded block 3, and a sealing groove 4 is provided on the top of the mounting block 1. The width of the sealing groove 4 is 5 cm, and the thickness of the sealing groove 4 is 2 cm. The grouting channel 5, the grouting channel 5 includes a slurry inlet channel 51 and a slurry outlet channel 52, the slurry inlet channel 51 is set in the inside of the protruding block 2 and runs through one side of the protruding block 2, and the grouting channel 52 is opened on the mounting block 1. Inside the protruding block 2 and the inner block 3 , one end of the pulp outlet channel 52 communicates with the pulp inlet channel 51 , and one e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com