Method for accurately controlling pressure difference at air inlet hole of automobile engine

An automobile engine, precise control technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve problems such as the safety threat of adjustment personnel, and it is difficult to control the accuracy of adjustment by manual manual adjustment, so as to reduce the risk of test operation and improve the accuracy of the adjustment. Control accuracy and response speed, the method is simple and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

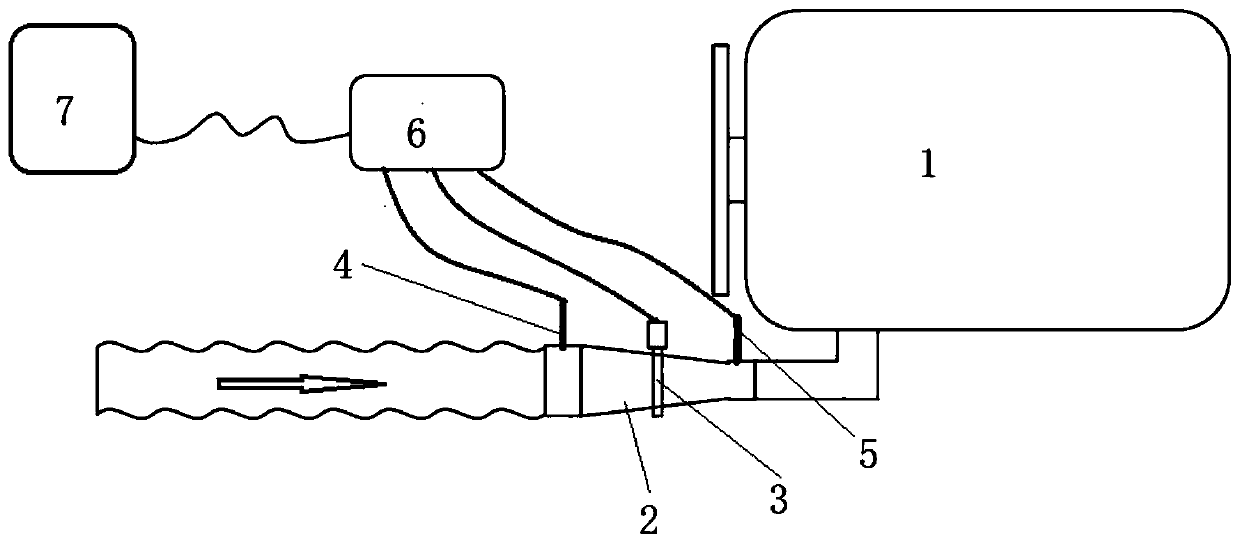

[0008] Such as figure 1 As shown, a method for accurately controlling the pressure difference at the intake port of an automobile engine is to install a solenoid valve 3 at the intake throat 2 of the engine 1, and install a first pressure sensor 4 and a second pressure sensor at the upstream and downstream of the solenoid valve respectively. 5. The solenoid valve, the first pressure sensor and the second pressure sensor are all connected to the control unit 6 through cables, and the control unit and the monitoring computer 7 are also connected through cables; Or the control unit sets the target value of the intake pressure difference at the engine intake port, the first pressure sensor and the second pressure sensor collect the intake pressure at two points before and after the solenoid valve in real time and transmit it to the control unit, and the control unit uses the pressure difference before and after the solenoid valve The deviation between the pressure difference and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com