Gas compressor system

A gas compressor and control system technology, applied in the direction of liquid variable capacity machinery, mechanical equipment, machines/engines, etc., can solve the problems of open control system, backward control technology, large impact on transformers and power grids, etc., to improve control Accuracy and response speed, solving the effect of backward control technology and reducing the impact of the power grid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The gas compressor system involved in the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

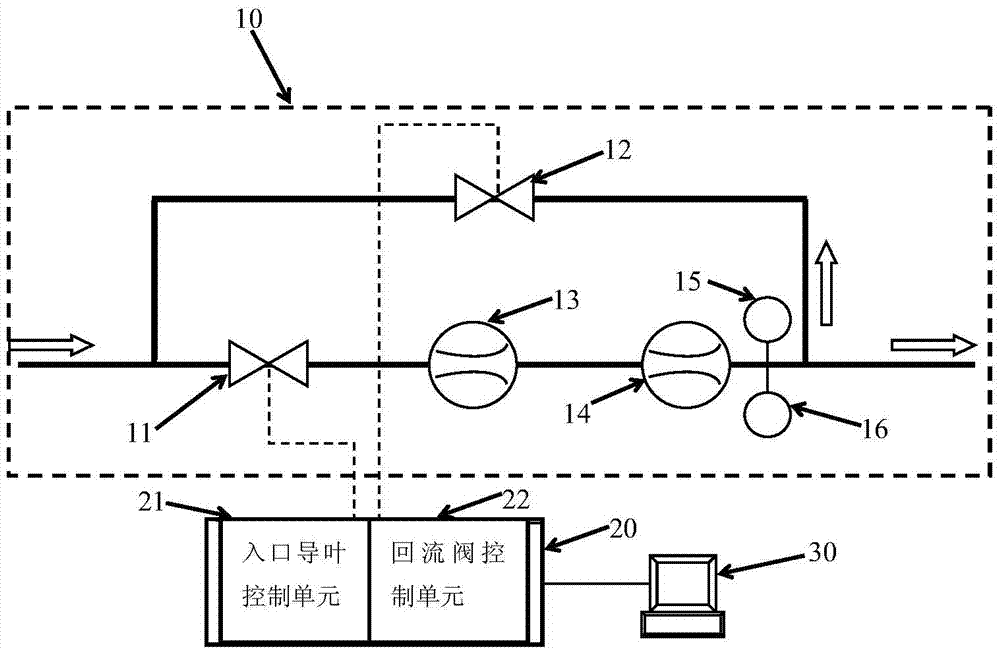

[0020] figure 1 is a system block diagram of the gas compressor system in the embodiment of the present invention.

[0021] Such as figure 1 As shown, the gas compressor system has: a gas compressor 10 , a control system 20 and a monitoring terminal 30 .

[0022] The gas compressor 10 has: an inlet guide vane 11 , a return valve 12 , a primary compression device 13 , a secondary compression device 14 , an outlet pressure gauge 15 and an outlet flow meter 16 .

[0023] The control system 20 has: an inlet guide vane control unit 21 and a return valve control unit 22 .

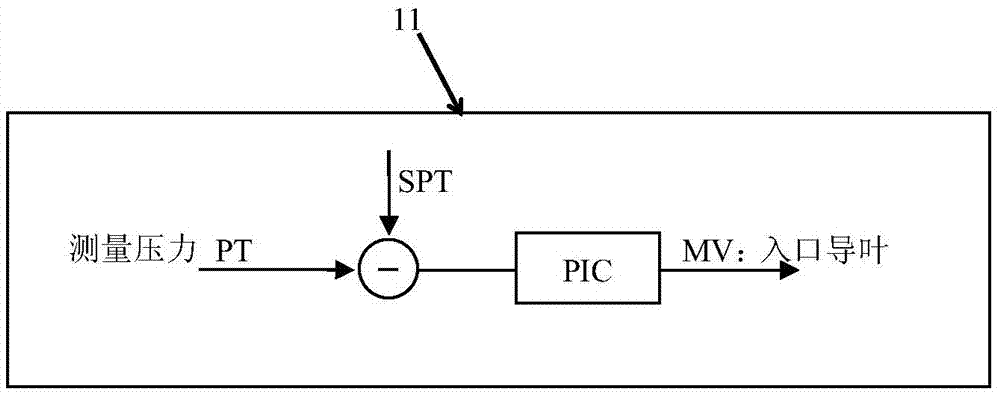

[0024] figure 2 is a system block diagram of the inlet guide vane in the embodiment of the present invention.

[0025] Such as figure 2 As shown, the inlet guide vane 11 is connected to the inlet guide vane control unit 21 of the control system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com