Multi-channel all-fiber microsphere resonant cavity based on space division multiplexing and manufacturing method of multi-channel all-fiber microsphere resonant cavity

A technology of microsphere resonator and space division multiplexing, which is applied in the direction of light guide, optics, optical components, etc., to achieve the effect of mechanical stability and high-power wide-spectrum optical coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

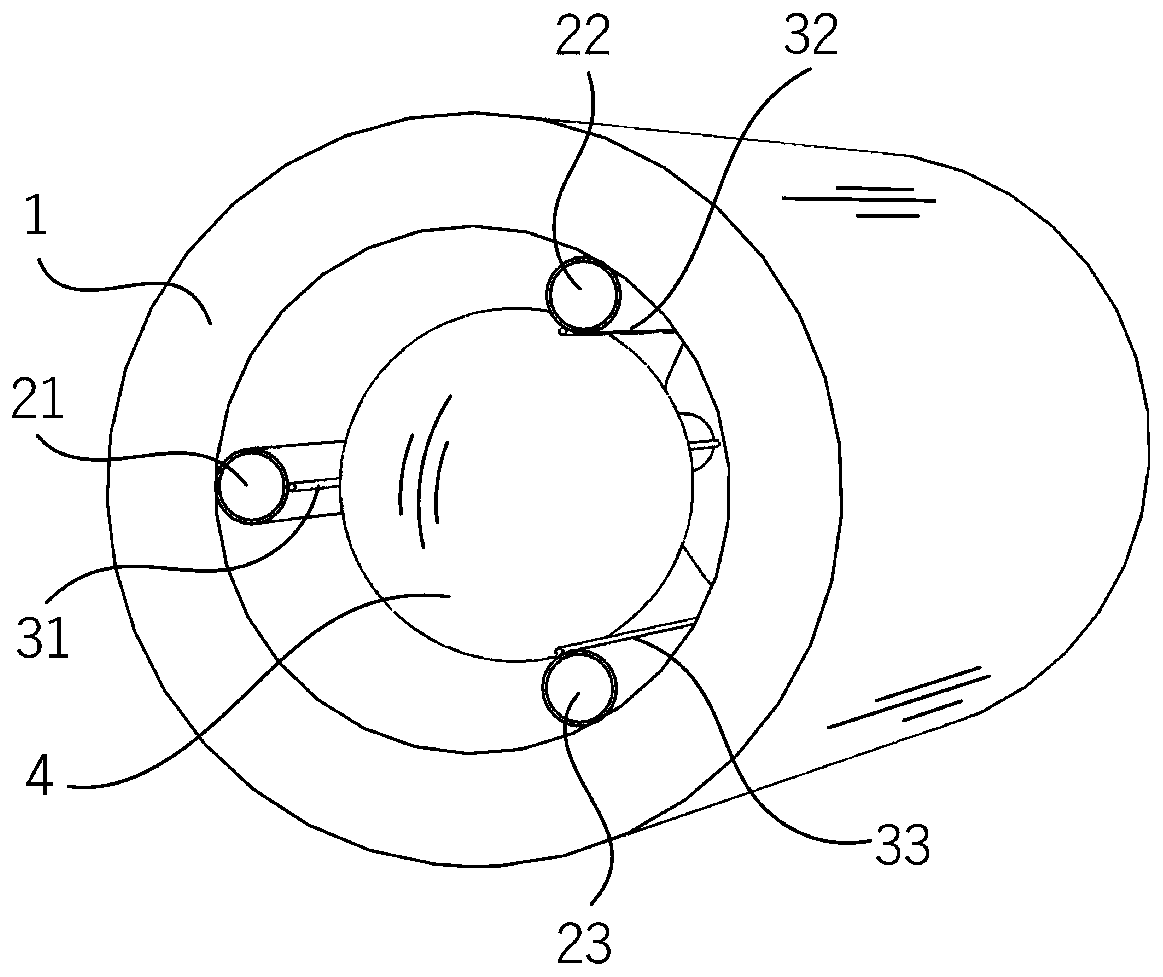

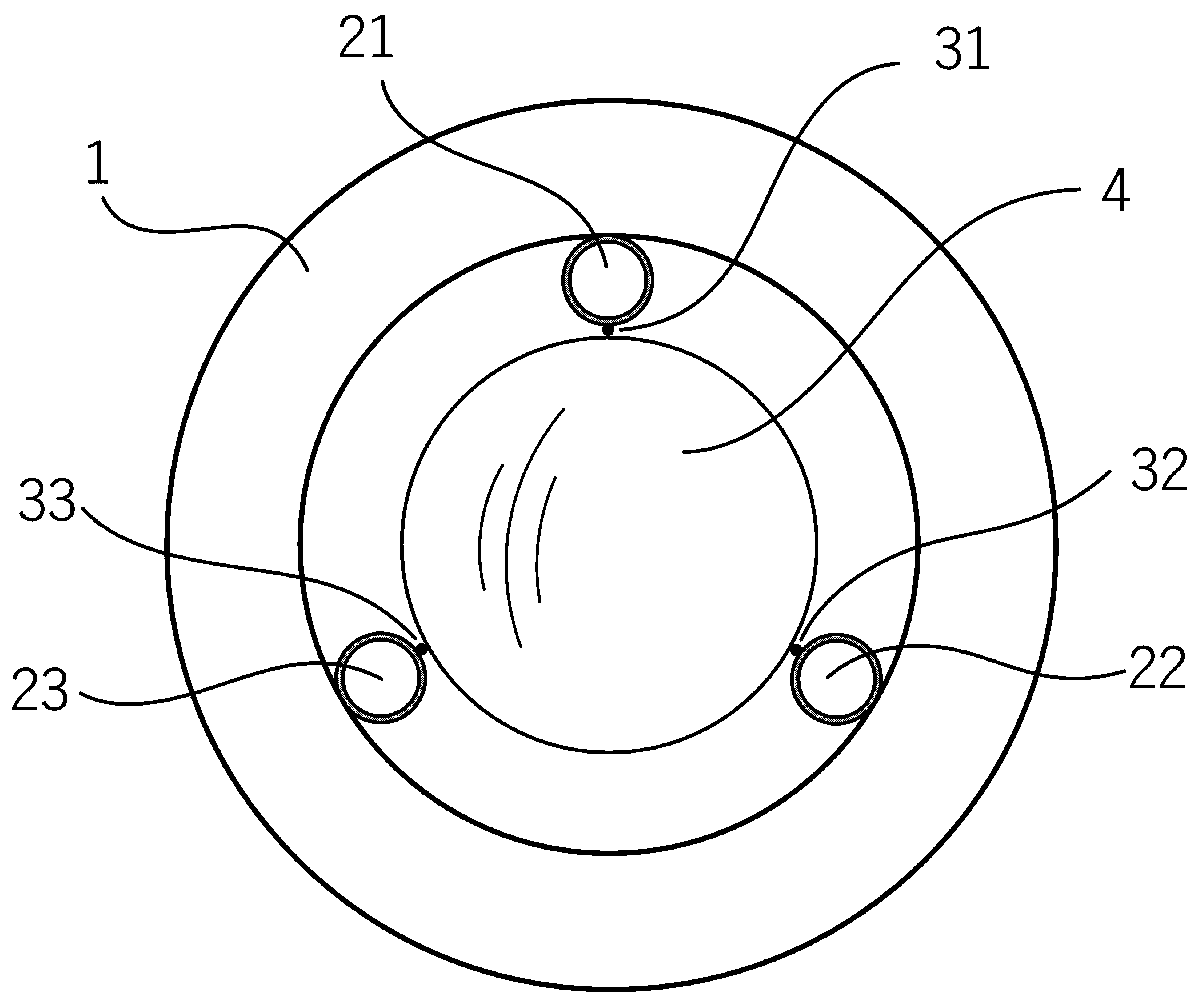

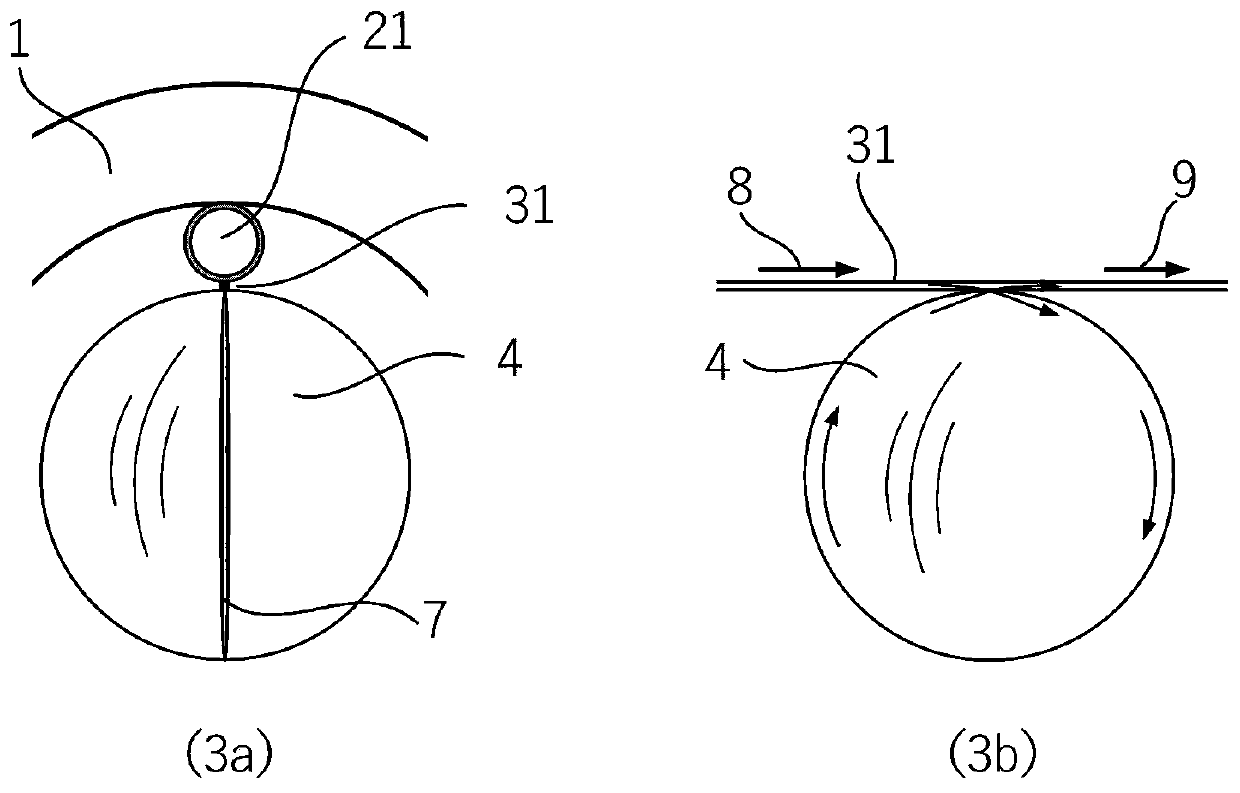

[0025] A multi-channel space-division multiplexed all-fiber microsphere resonator structure proposed by the present invention adopts the combination of the hollow microstructure optical fiber and the microsphere resonator to realize the all-fiber microsphere resonator structure; at the same time, the microsphere surface forms The space division multiplexing function of the optical resonant cavity realizes the goal of multi-channel light output.

[0026] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] Such as figure 1 As shown, it is a schematic diagram of the multi-channel all-fiber microsphere resonance structure based on space division multiplexing of the present invention, the structure includes an optical fiber cladding 1, an optical waveguide supporting micropipe, a highly doped germanium optical waveguide and microspheres 4; a highly doped germanium The optical waveguide is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com