Trough-type self-absorption potted plant culture system and culture method

A cultivation system and cultivation method technology, which are applied to a trough-type self-priming pot cultivation system and the cultivation field thereof, can solve the problems of no water storage function, loss of water and fertilizer, poor soil moisturizing performance, etc., so as to reduce fertilization and separate Irrigation work, preventing fertilizer loss, saving space and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

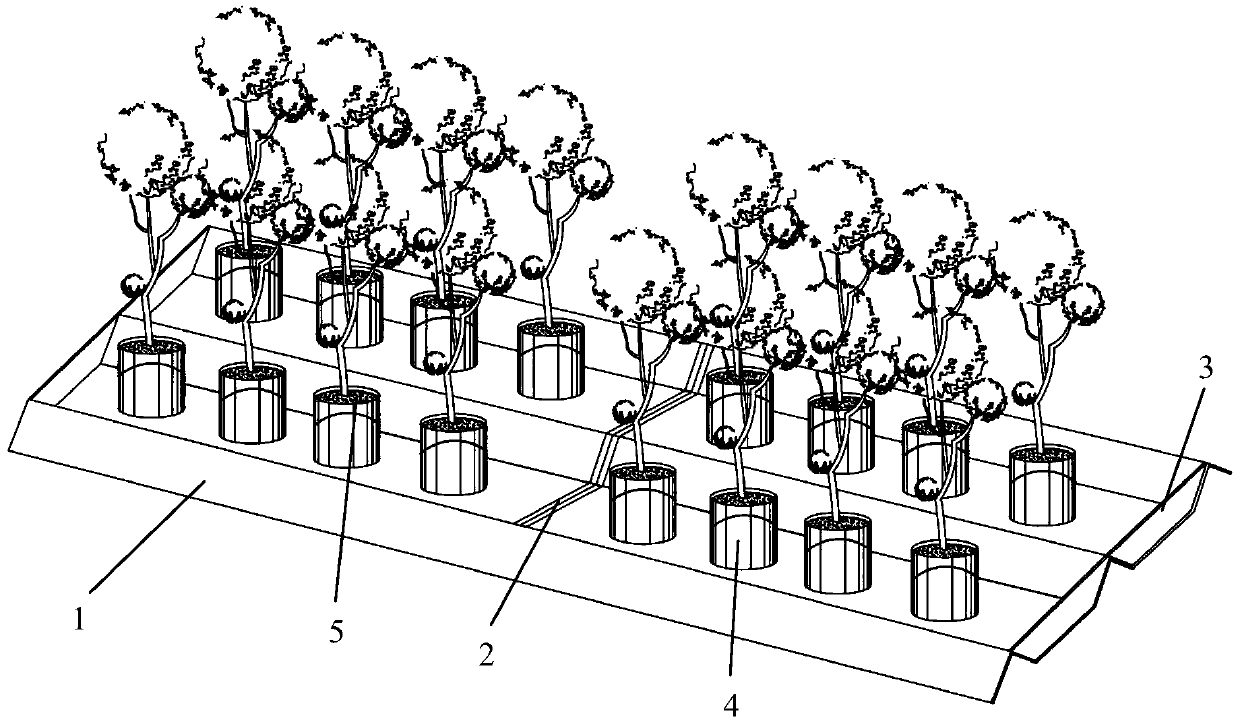

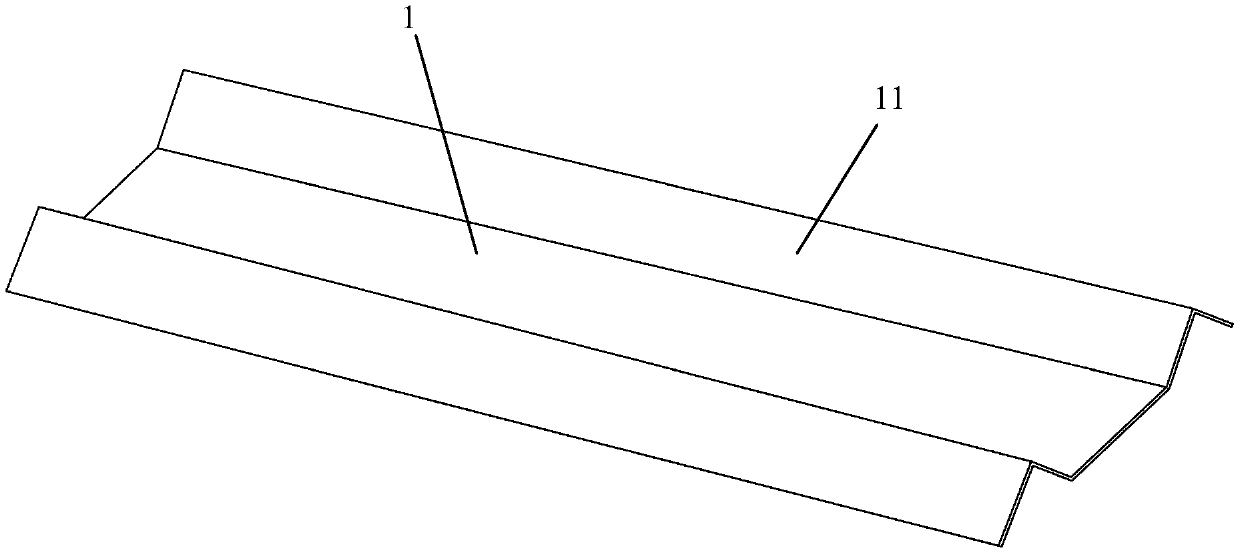

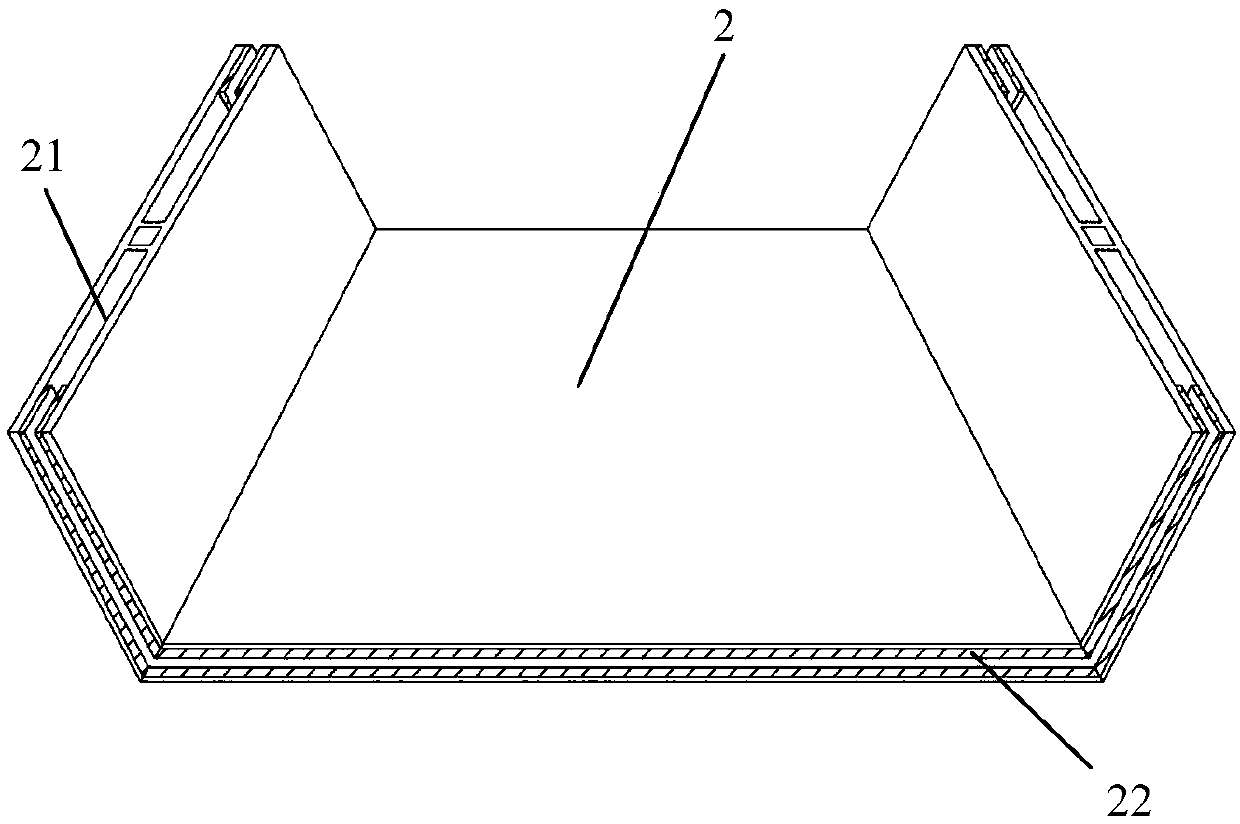

[0039] See attached figure 1 To attach Figure 4 , the embodiment of the present invention discloses a trough-type self-priming potted plant cultivation system, comprising: several long troughs 1, the ends of the long troughs 1 are open at both ends, and the trough walls 11 on both sides of the long troughs 1 are inverted " V"-shaped structure; the head and tail of several long tanks 1 are sealed and connected by connectors 2, and the V-shaped structures of the tank walls 11 of several long tanks 1 are stacked and arranged side by side. A sealing member 3 for blocking is also provided; culture pots 4 are evenly placed in the elongated tank body 1, and water absorption holes are provided at the bottom of the culture pot 4.

[0040] It should be noted that the longitudinal connection length and the number of rows arranged horizontally of the elongated tank body 1 are set according to the actual production situation. There is a passage in the 2-3 columns for the planters to wal...

Embodiment 2

[0052] See attached figure 1 to attach Figure 4 , the embodiment of the present invention discloses a trough-type self-priming potted cultivation method, specifically comprising the following steps:

[0053] Step 1: Seal the ends of several long tanks 1 through connectors 2, the connection length is set according to the actual situation, and seals 3 for sealing the openings at both ends are provided at the ends of the final connected and formed tanks;

[0054] Step 2: Fit and arrange the groove walls 11 of several elongated groove bodies 1 side by side, and set the number of rows according to the actual situation;

[0055] Step 3: Place the culture pot 4 with water absorption holes at the bottom evenly in the tank, and the culture pot 5 is provided with a long-acting fertilizer culture substrate 5;

[0056] Step 4: Irrigate and deliver water, deliver water at one end of each row of tanks until the tanks are filled with water and stop.

[0057] In order to further optimize ...

Embodiment 3

[0063] See attached figure 1 to attach Figure 4 , the embodiment of the present invention discloses a trough-type self-priming potted cultivation method, specifically comprising the following steps:

[0064] Step 1: Seal the ends of several long tanks 1 through connectors 2, the connection length is set according to the actual situation, and seals 3 for sealing the openings at both ends are provided at the ends of the final connected and formed tanks;

[0065] Step 2: Fit and arrange the groove walls 11 of several elongated groove bodies 1 side by side, and the number of rows set is 2-3;

[0066] Step 3: Place the culture pot 4 with water absorption holes at the bottom evenly in the tank, and the culture pot 5 is provided with a long-acting fertilizer culture substrate 5;

[0067] Step 4: Irrigate and deliver water, deliver water at one end of each row of tanks until the tanks are filled with water and stop.

[0068] In order to further optimize the above-mentioned technic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com