Auxiliary turnover device for tube bundle assembly and turnover method using auxiliary turnover device

A component and fixed component technology, applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of difficulty in the vertical assembly process of tube bundle components and shell components, and achieve low manufacturing difficulties and easy installation and disassembly, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

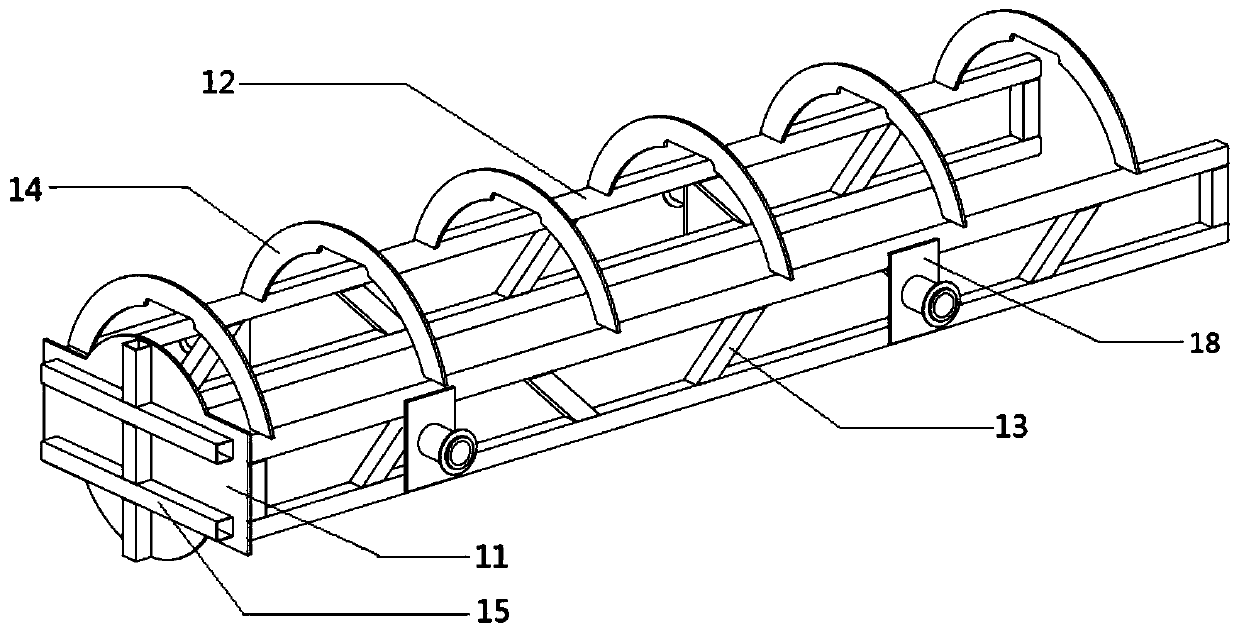

[0139] An auxiliary turn-over device for a tube bundle assembly of the present invention is applied to the turn-over process of the tube bundle assembly in the production process of the waste heat discharge heat exchanger of the ACP1000 nuclear power project.

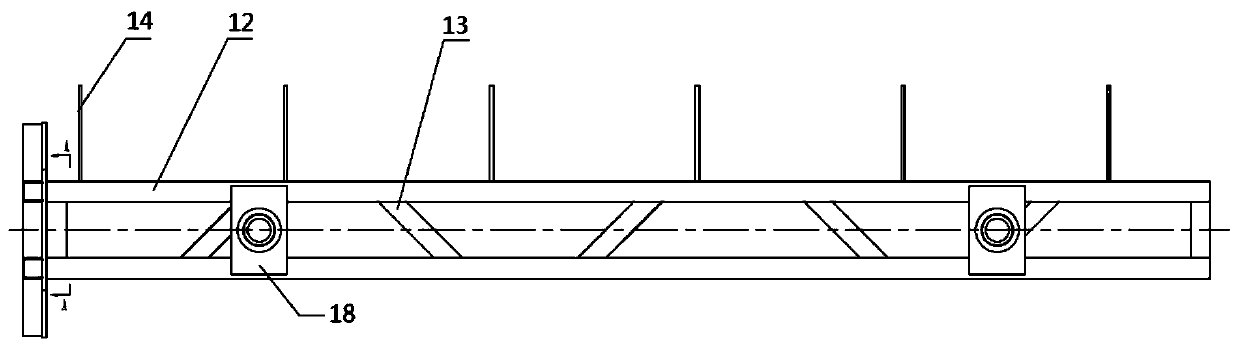

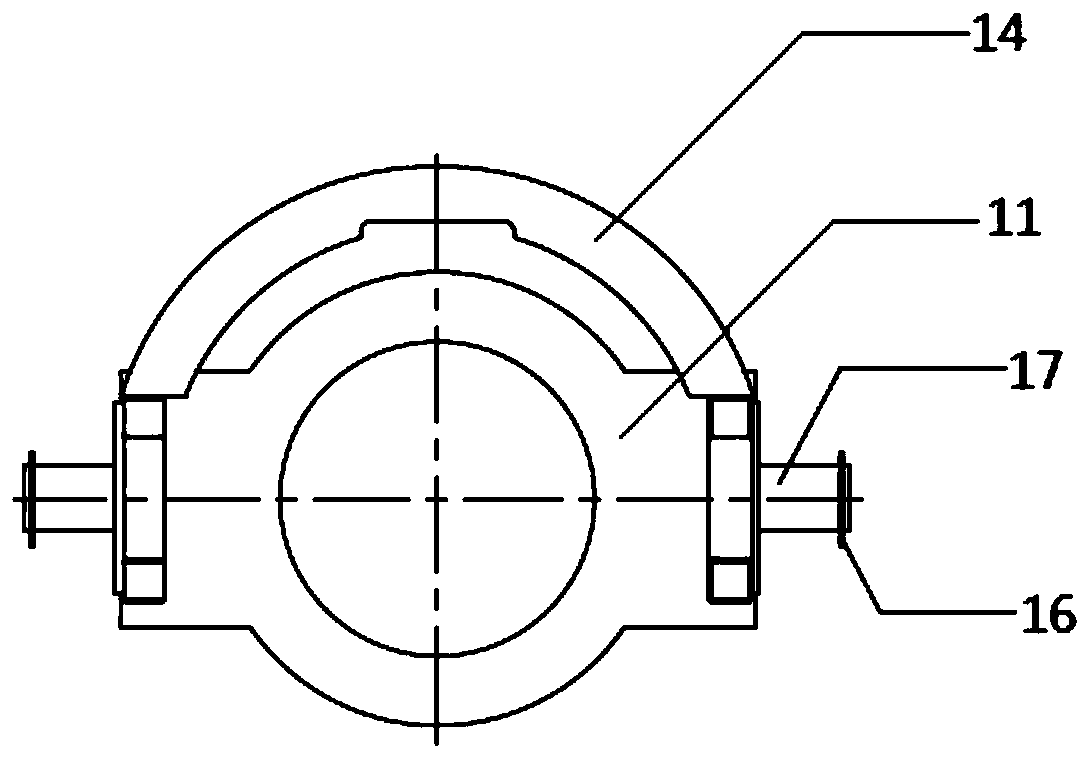

[0140] Wherein, in the tube bundle assembly auxiliary turning device adopted in this embodiment, the bottom plate 11 of the main frame is a stainless steel plate, and a short square tube 15 is welded on the lower surface, such as Figure 4 shown.

[0141] Four rectangular tubes 12 are arranged on the upper surface of the bottom plate, and the four rectangular tubes 12 form a cuboid frame on the bottom plate 11 . On the second side and the fourth side of the cuboid frame, a plurality of oblique pipes 13 are welded, and at both ends of the second side and the fourth side, the included angle between the oblique pipe 13 and the rectangular pipe 12 is 90° °, the angle a between the remaining rhombic tubes 13 and the rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com