A kind of biomedical material and preparation method thereof

A technology of biomedical and metal materials, applied in the field of biomedical materials and their preparation, can solve problems such as implant corrosion, tissue influence, implant bacterial infection, etc., and achieve improved corrosion resistance, enhanced antibacterial, and good combination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the preparation of biomedical metal material

[0035] (1) Grind and polish the surface of a bulk Ti-45Nb alloy sample with a size of 10mm×10mm×3mm to 1200#, then ultrasonically clean it with a cleaning agent prepared by ethanol and acetone with a volume ratio of 4:1, and then dry it ;

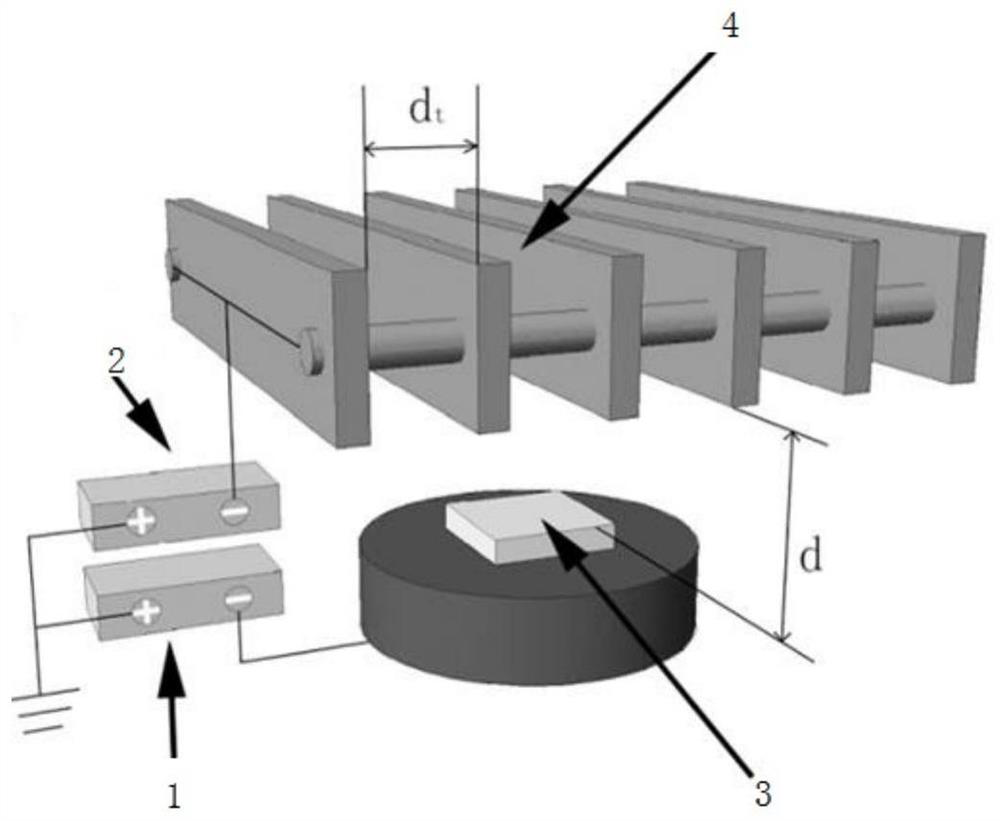

[0036] (2) Put the processed Ti-45Nb alloy sample and Zr-Ag alloy target into the double-glow plasma surface metallurgy metal infiltration furnace. The Zr content in the Zr-Ag alloy target is 80% by mass percentage, and the Ag The content is 20%, the Ti-45Nb alloy sample is used as the workpiece electrode, the Zr-Ag alloy target is used as the source electrode, and the distance between the two electrodes is adjusted to 20mm;

[0037] (3) Turn on the mechanical pump, then open the exhaust valve, evacuate to below 0.2Pa, ensure the vacuum in the furnace, and close the exhaust valve;

[0038] (4) Turn on the argon gas bottle, open the argon gas valve, and then turn on the fl...

Embodiment 2

[0049] Embodiment 2: the preparation of biomedical metal material

[0050] (1) Grind and polish the surface of a bulk Ti-45Nb alloy sample with a size of 10mm×10mm×3mm to 1200#, then ultrasonically clean it with a cleaning agent prepared by ethanol and acetone with a volume ratio of 4:1, and then dry it ;

[0051] (2) Put the treated Ti-45Nb alloy sample and Zr-Ag mixed grid-shaped target into the double-glow plasma surface metallurgy metal infiltration furnace. The Zr target is high-purity zirconium (purity above 99.95%), and the Ag target is It is high-purity silver (purity above 99.99%), and it is connected by pure zirconium rods arranged at intervals. The Zr content in the Zr-Ag alloy target is calculated as 50% by mass percentage, and the Ag content is 50%. The Ti-45Nb alloy sample is used as For the workpiece pole, the Zr-Ag mixed grid target is used as the source pole, and the distance between the two poles is adjusted to 25mm;

[0052] (3) Turn on the mechanical pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com