Continuous operating type convenient-locating ironing device for garment production

A clothing and operation technology, which is applied in the field of clothing production, can solve problems such as low work efficiency, damp clothing, and clothing cleaning treatment, and achieve the effects of convenient and fast installation, improved work efficiency, and good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

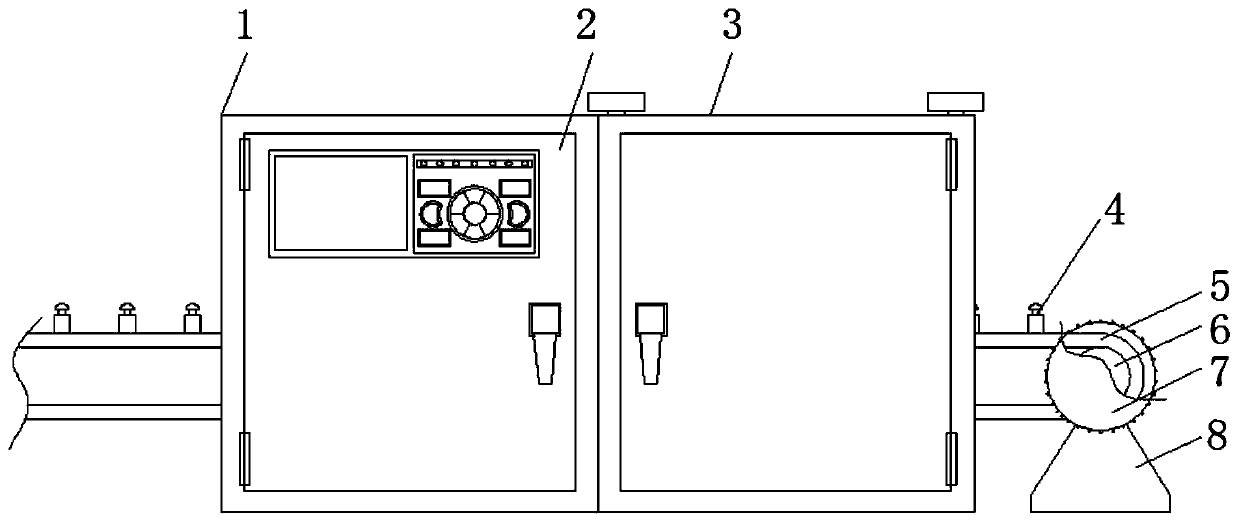

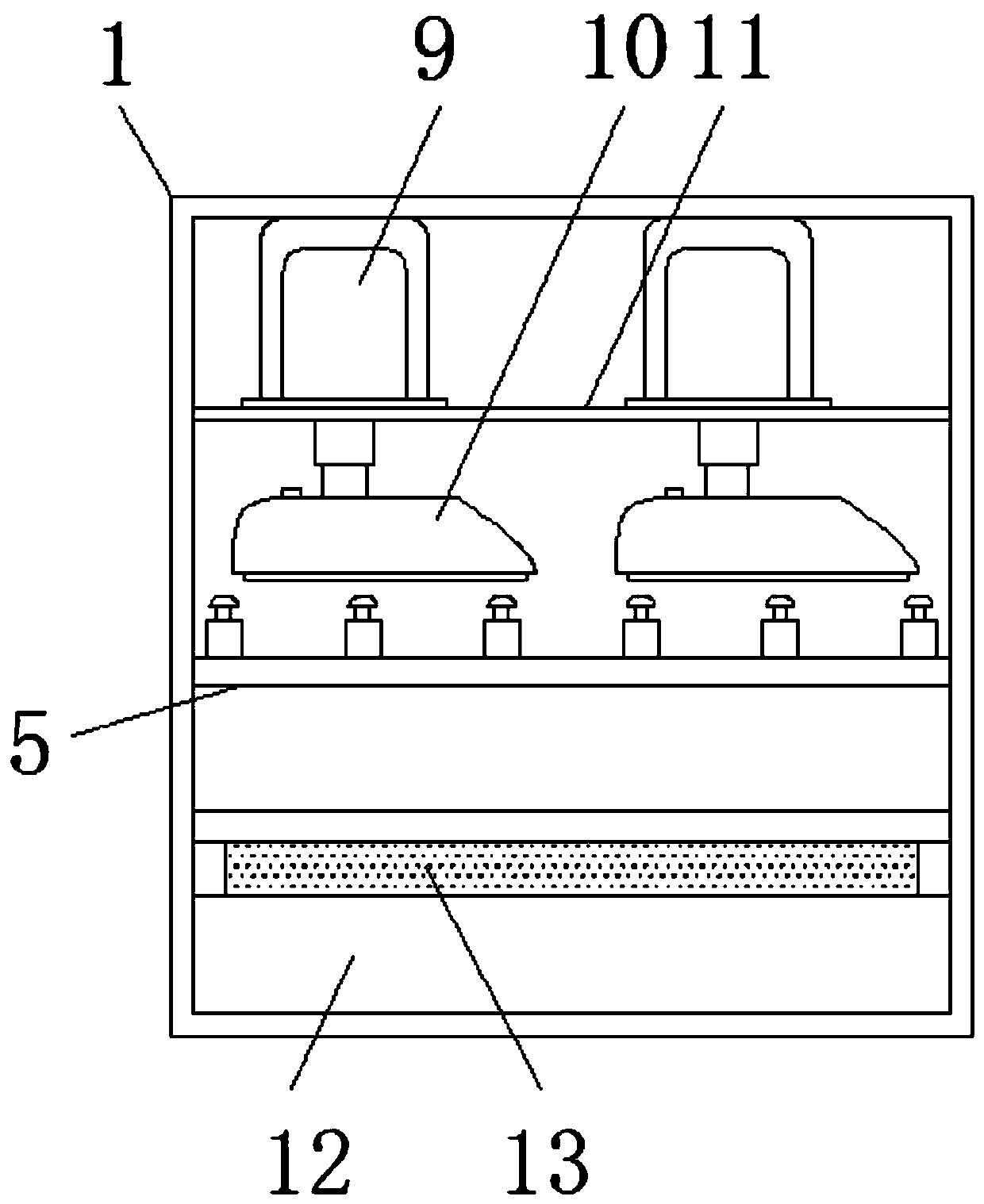

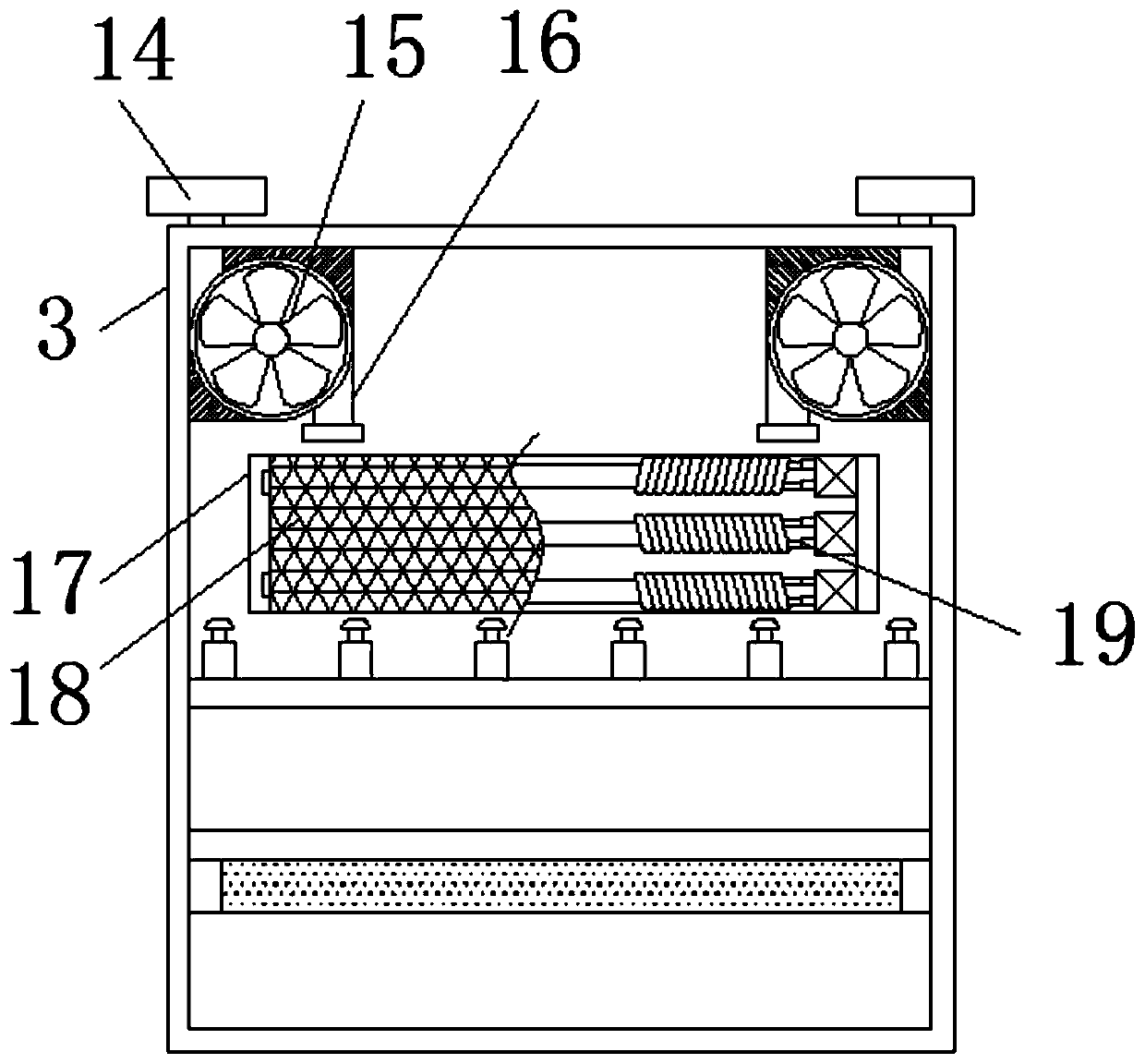

[0027] see Figure 1-6, a continuous operation type ironing device for garment production that is convenient for positioning, comprising a casing a1 and a casing b3, the casing b3 is fixedly installed on one side of the outer wall of the casing a1, the casing a1 and the casing The exterior of b3 is equipped with an organic door 2 through hinges, and a handle is fixedly installed on the door 2. By installing the organic door 2, the structure inside the casing a1 and casing b3 can be effectively protected, and can be opened by the handle. The casing a1 and the casing b3, one side of the casing b3 is fixedly installed with a driving motor 7 through a support 8, and one end of the rotating shaft installed on the output end of the driving motor 7 is fixedly installed with a drive roller shaft 6. Conveyor belt 5 is installed on the transmission roller s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com