System and method for manufacturing underwear fabric and underwear fabric

A technology of underwear fabric and manufacturing system, which is applied in the cutting of underwear, textiles, papermaking, and textile materials. It can solve the problems of automatic processing of underwear and achieve good cutting effect and uniform force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

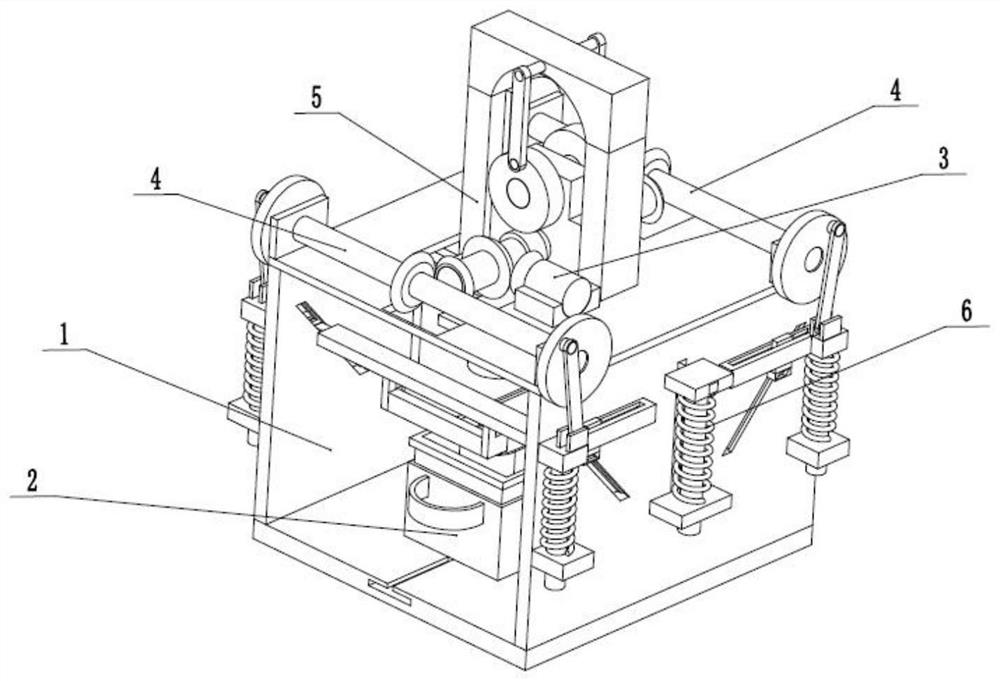

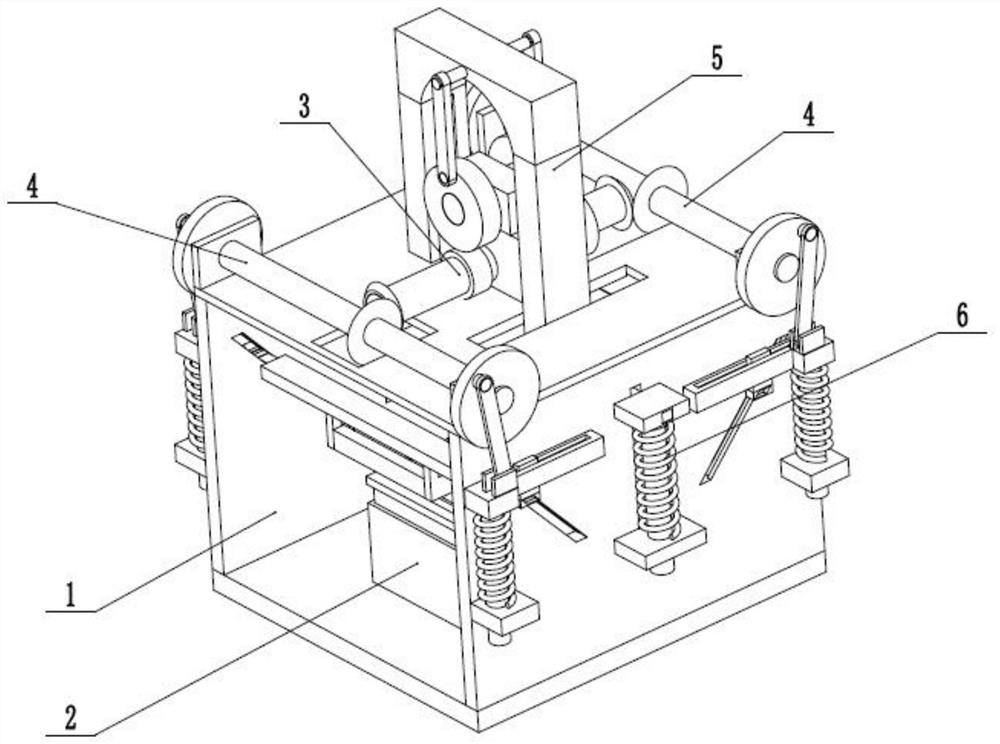

[0034] like Figure 1 to Figure 11 As shown, a kind of underwear fabric manufacturing system includes a fixed cutting base 1, a receiving combined cutting base 2, a drive connector 3, two inclined driving extrusion fixers 4, an upper connection driver 5 and a combined cutter 6, the described The receiving combined cutting base 2 is slidably connected in the fixed cutting base 1, and the driving connector 3 is fixedly connected to the upper end of the fixed cutting base 1, and the two ends of the driving connector 3 are respectively meshed with transmission and connected to two inclined driving extrusion holders 4, the two A tilt-driven extruding fixer 4 and combined cutter 6 are all slidably connected to the fixed cutting base 1, the upper connection driver 5 is hinged on the drive connector 3, and the combined cutter 6 is fixedly connected to the lower end of the upper connection driver 5, combined The lower end of cutter 6 fits with receiving combination cutting seat 2. Sli...

specific Embodiment approach 2

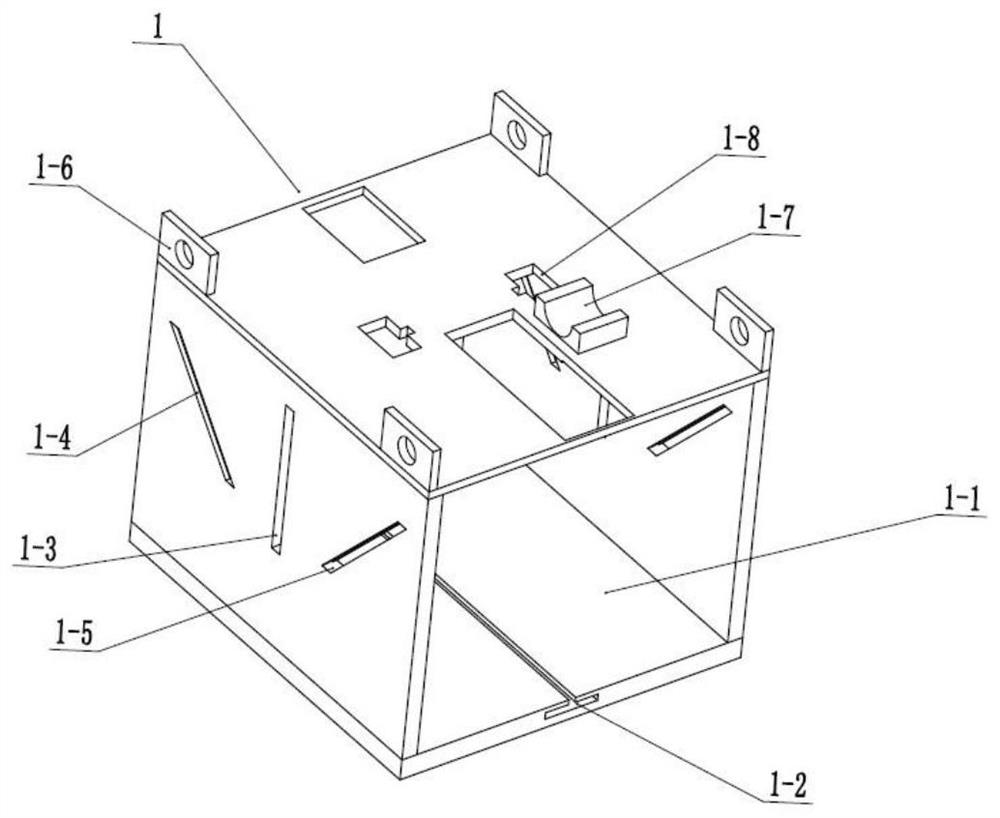

[0036] like Figure 1 to Figure 11 As shown, this embodiment will further describe Embodiment 1. The fixed cutting base 1 includes an operating frame 1-1, a T-shaped sliding groove 1-2, two vertical sliding grooves 1-3, and two rear inclined sliding grooves. 1-4, two front inclined sliding grooves 1-5, four rotating seats 1-6, motor fixing seats 1-7 and two limit slider grooves 1-8, set on the lower side of the inner wall of the operating frame 1-1 There are T-shaped sliding grooves 1-2, two vertical sliding grooves 1-3 run through the center of the two ends of the operation frame 1-1 respectively, and two rear inclined sliding grooves 1-4 run through the centers of the two ends of the operation frame 1-1 respectively. On the rear side, two front inclined sliding grooves 1-5 are respectively set on the front side of the two ends of the operation frame 1-1, and the four rotating seats 1-6 are evenly and fixedly connected to the upper end of the operation frame 1-1, and the moto...

specific Embodiment approach 3

[0038] like Figure 1 to Figure 11 As shown, this embodiment further explains the second embodiment, the receiving combined cutting seat 2 includes a load recovery frame 2-1, a T-shaped sliding block 2-2, a handle ring 2-3, and a forming matching bottom sleeve 2-4. The left extruded and fixed U-shaped groove 2-5 and the right extruded and fixed U-shaped groove 2-6 are fixedly connected with the lower end of the load recovery frame 2-1 to the T-shaped sliding block 2-2, which is the load recovery frame 2 -1 is slidably connected in the T-shaped sliding groove 1-2 through the T-shaped sliding block 2-2, the handle ring 2-3 is fixedly connected to the load recovery frame 2-1, and the forming matching bottom sleeve 2-4 is fixedly connected to the In the load recovery frame 2-1, the left extruded and fixed U-shaped groove 2-5 and the right extruded fixed U-shaped groove 2-6 are respectively arranged on the upper sides of the two ends of the load recovery frame 2-1. When it is nece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com