Construction method of three-dimensional tunnel group structure

A technology of tunnel structure and construction method, which is applied in the direction of basic structure engineering, underwater structures, excavation, etc. It can solve the problems of difficult construction of airport passages, passages cannot be arranged side by side, and slow construction speed, so as to reduce construction costs and improve construction efficiency. Efficiency and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

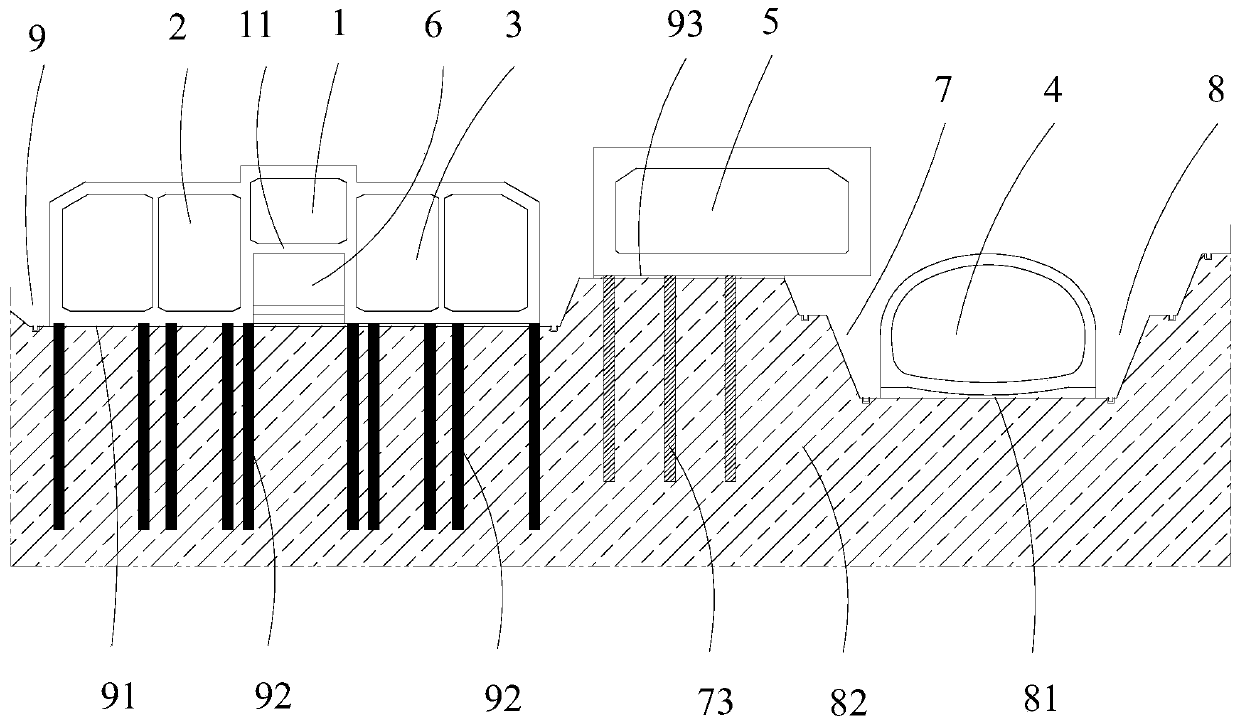

[0125] like figure 1 and 11 As shown, a construction method of a three-dimensional tunnel group structure comprises the following steps:

[0126] S1. Excavating the first foundation pit 9 to the first bottom surface 91;

[0127] S2. setting a plurality of first support piles 92 on the first bottom surface 91;

[0128] S3. Carry out the construction of the first tunnel structure 1, the second tunnel structure 2 and the third tunnel structure 3 on the first support pile 92, wherein, between the second tunnel structure 2 and the third tunnel structure 3 A first bottom plate 11 is connected, and the first bottom plate 11, the second tunnel structure 2 and the third tunnel structure 3 form a first tunnel structure 1 and a first cavity 6, and the first cavity 6 is located in Below the first bottom plate 11;

[0129] S4. After the construction of the first tunnel structure 1, the second tunnel structure 2 and the third tunnel structure 3 is completed, the first cavity 6 is backfi...

Embodiment 2

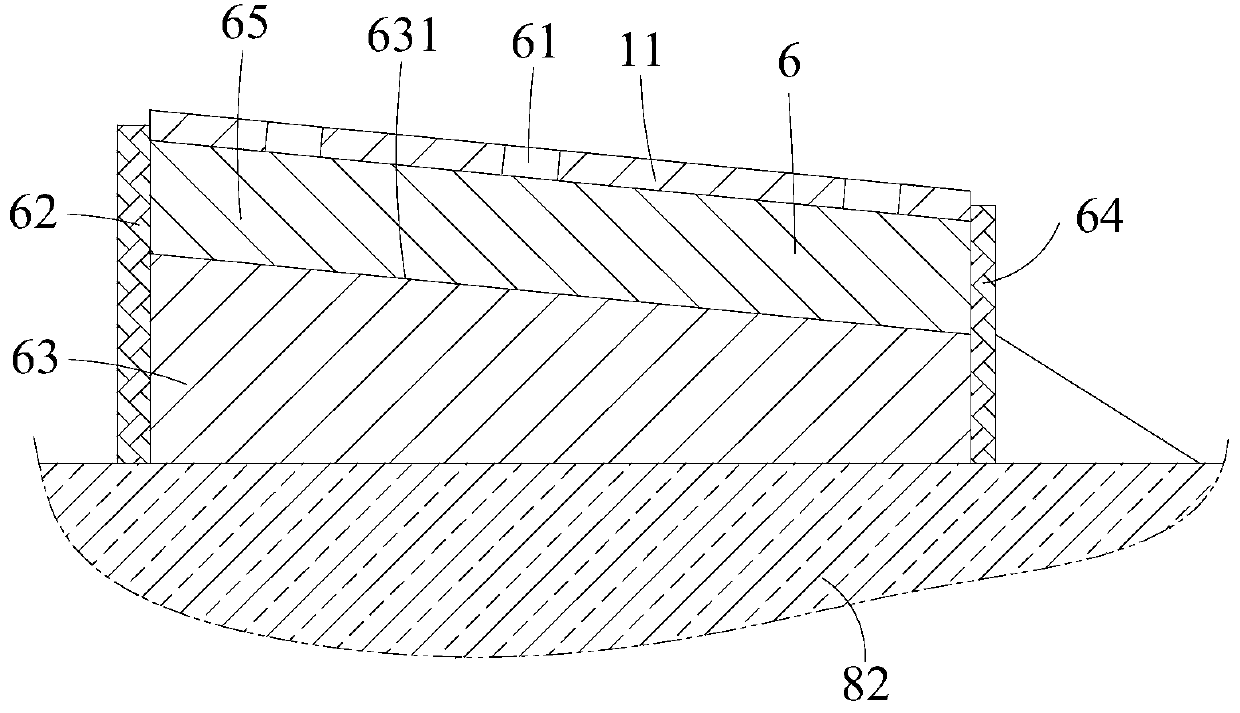

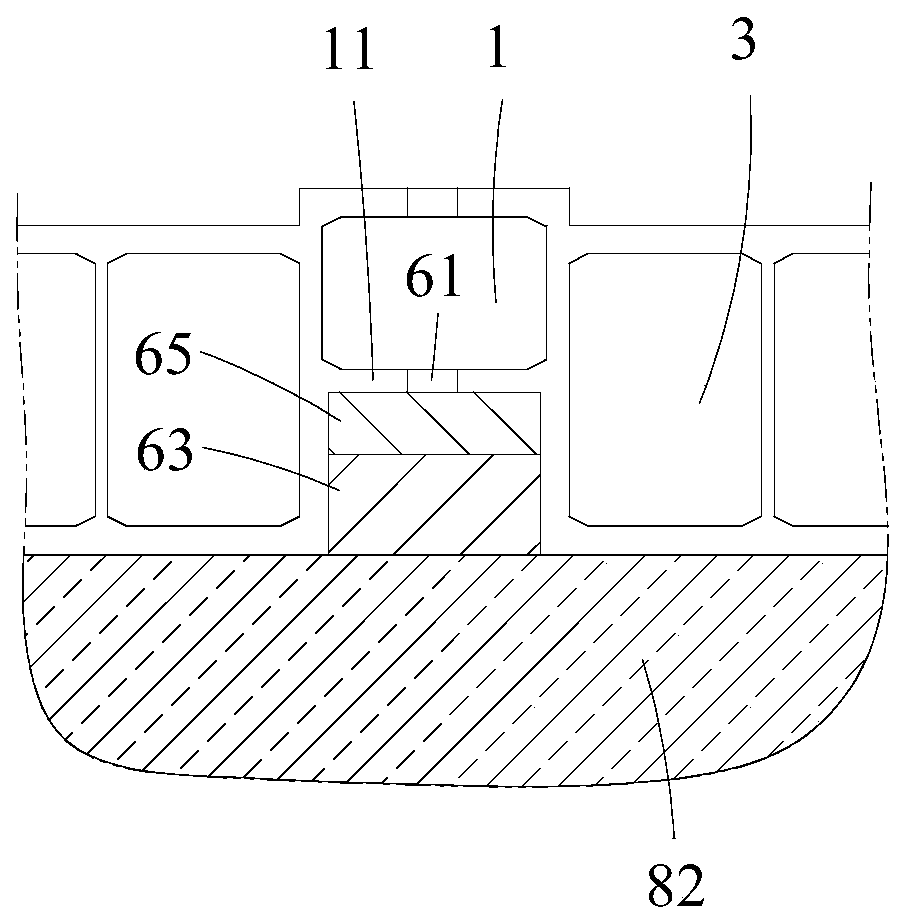

[0139] like Figure 2-4 As shown, the construction method of a three-dimensional tunnel group structure described in this embodiment is different from Embodiment 1 in that one end of the first cavity 6 is sealed and connected with a first sealing wall 62, and the The other end of the first cavity 6 is sealed and connected with a second sealing wall 64, and a top backfill layer structure 65 and a bottom backfill layer structure 63 are arranged in the first cavity 6 from top to bottom, and the top backfill layer structure 65 and the bottom backfill layer structure 63 jointly fill the first cavity 6, the top backfill layer structure 65 is made of self-compacting material filling, and the bottom backfill layer structure 63 has a 65 in contact with the first top surface 631, there is a first gap between the first top surface 631 and the first bottom plate 11, the first bottom plate 11 is provided with at least one cavity 6 It is connected to the inlet 61 through which the filler o...

Embodiment 3

[0151] like Figure 5-8 As shown, the construction method of a three-dimensional tunnel group structure described in this embodiment is different from Embodiment 1 or 2 in that the construction method also uses an outer mold trolley 41, an inner mold trolley 42 and a For the steel bar trolley 43 for binding steel bars, the step S6 includes the following steps:

[0152] S61. Utilize the reinforcing bar trolley 43 to bind the reinforcing bars to form an arched reinforcing cage 44 for the fourth tunnel structure 4, and the reinforcing bar trolley 43 is located inside the arched reinforcing cage 44;

[0153] S62. Move the outer mold trolley 41 to the outside of the arched reinforcement cage 44, and use a stabilizer 411 to mount and connect the arched reinforcement cage 44, and connect the reinforcement trolley 43 to the arched reinforcement cage. The cage 44 is separated from each other, and the stabilizing device 411 is arranged on the outer mold trolley 41;

[0154]S63. Moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com