Elastic anti-seismic device for wooden beams and its installation method

A technology of anti-seismic device and installation method, applied in the direction of anti-seismic, joists, girders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

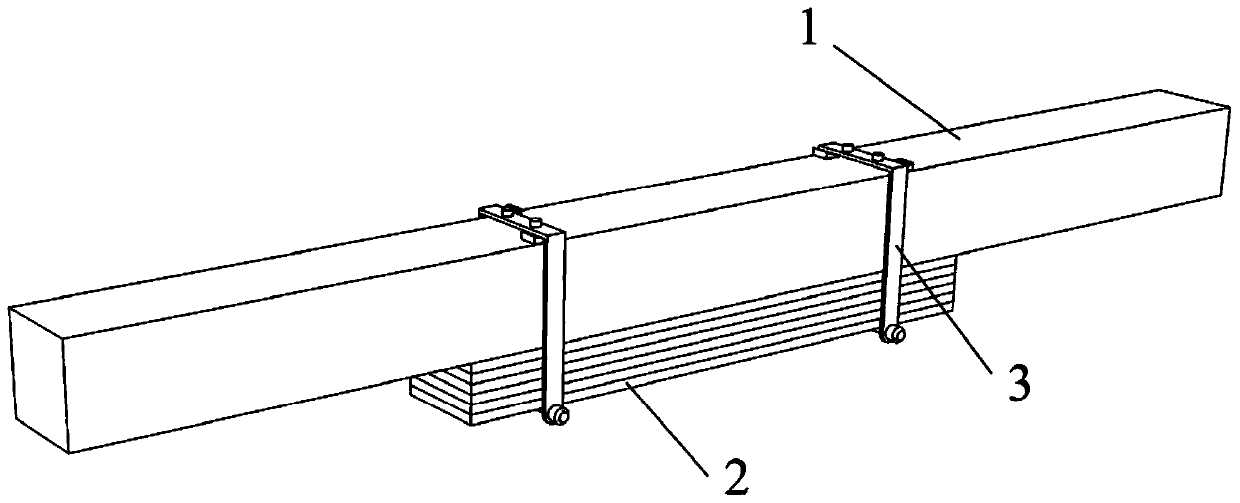

[0050] Such as figure 1 As shown, the elastic anti-seismic device of the wooden beam includes several layers of wooden boards 2 arranged under the wooden beam 1. The wooden board 2 has at least two layers, and two U-shaped clamps 3 are used to tightly fix the two parts of the wooden beam 1 and the wooden board 2. end, the opening 4 of the U-shaped clamp 3 faces downward, that is, the U-shaped clamp 3 is installed on the upper end surface and side of the wooden beam 1, the opening 4 is provided with a pull bolt hole, and the pull bolt 5 runs through the Both ends of the pull bolt holes are fixed by nuts 6; the opening positions of the pull bolt holes are prefabricated according to the sum of the thickness of the plank 2 of all layers and the thickness of the wooden beam 1, and the two U-shaped clamps 3 along the Plank 2 length direction is set by actual distance; U-shaped clamp 3 inboard width is equal to described wooden beam 1 width, and U-shaped clamp 3 side height exceeds t...

Embodiment 2

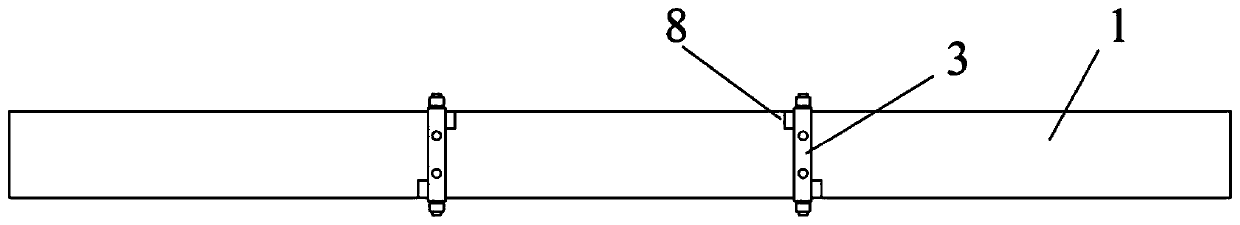

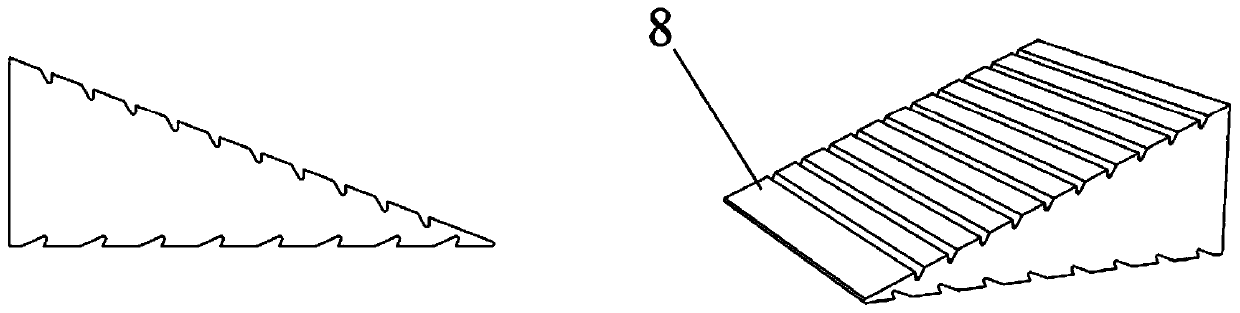

[0072] Such as Figure 5 ~ Figure 7 As shown, the elastic anti-seismic device of the wooden beam includes several layers of equal-length wooden boards 2 arranged under the wooden beam 1, the wooden boards 2 are at least two layers, and the U-shaped clamp 3 tightly fixes the wooden beam 1 and the wooden board 2, so The opening 4 of the U-shaped clamp 3 faces downward, that is, the U-shaped clamp 3 is installed on the upper end surface and the side of the wooden beam 1, and the lower end of the U-shaped clamp 3 extends toward the middle of the plank 2 and forms a cross brace 9. The two cross braces 9 are all provided with through holes, and the corresponding positions of the planks 2 and the through holes are provided with positioning holes, and the positioning bolts 7 are interference fit and located at the corresponding through holes and the In the positioning hole, the interference fit of the interference fit is 0.1-0.2mm. The upper end surface of the U-shaped clamp 3 is cov...

Embodiment 3

[0085] Such as Figure 8-9 As shown, the difference between the present embodiment and embodiment 2 is only that the elastic anti-seismic device of the wooden beam includes several layers of planks 2 arranged in a fish-belly shape arranged below the wooden beam 1, and the planks 2 are at least three layer, and the U-shaped clamp 3 tightly fixes the wooden beam 1 and the wooden board 2 . There are at least three U-shaped clamps 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com