Railway tunnel lining construction method based on medium and high fluidity concrete

A technology with high fluidity and construction method, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of poor pumpability of pumped concrete, inability to meet on-site construction, poor concrete discreteness, etc. Workability and suitability, effect of improving compactness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

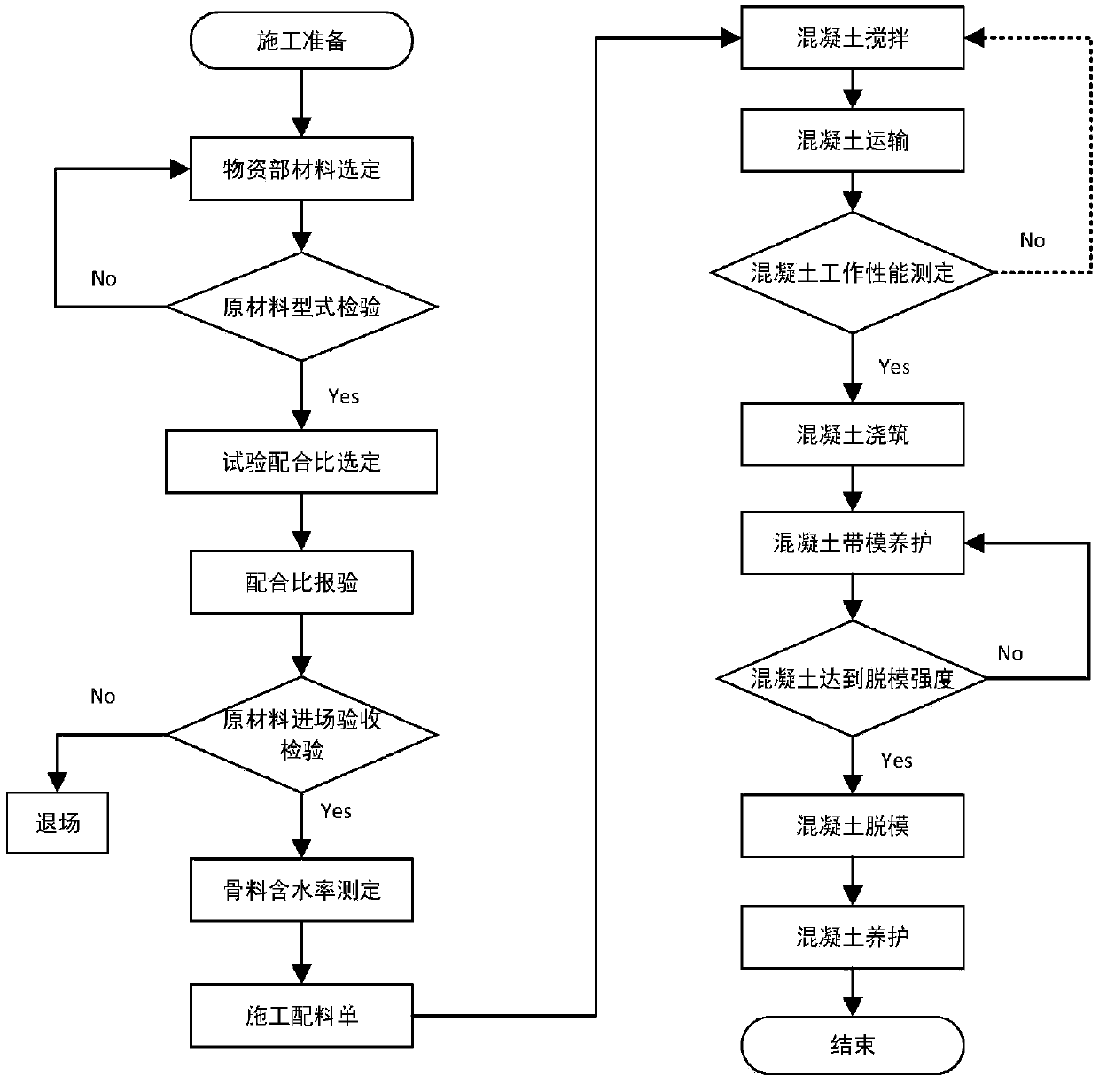

[0043] 1. Concrete mixing

[0044] 1) The mixing capacity of the mixing station on the construction site should meet the requirements of continuous pouring on site, and at least two sets of mixing equipment with a rated production capacity of not less than 90m3 / h should be equipped; to use.

[0045] 2) The moisture content of coarse and fine aggregates should be measured before concrete mixing, and the construction mix ratio should be adjusted in time. At least one test per shift, and the number of tests should be increased when the moisture content changes significantly.

[0046] 3) Concrete mixing time should be determined through experiments according to the mix ratio and mixing equipment, but the shortest time should not be less than 2 minutes, and should not be less than 90s, and fiber concrete and winter concrete should be extended by 30s.

[0047] 4) The production information of the mixing station has the functions of automatic recording, uploading and storage.

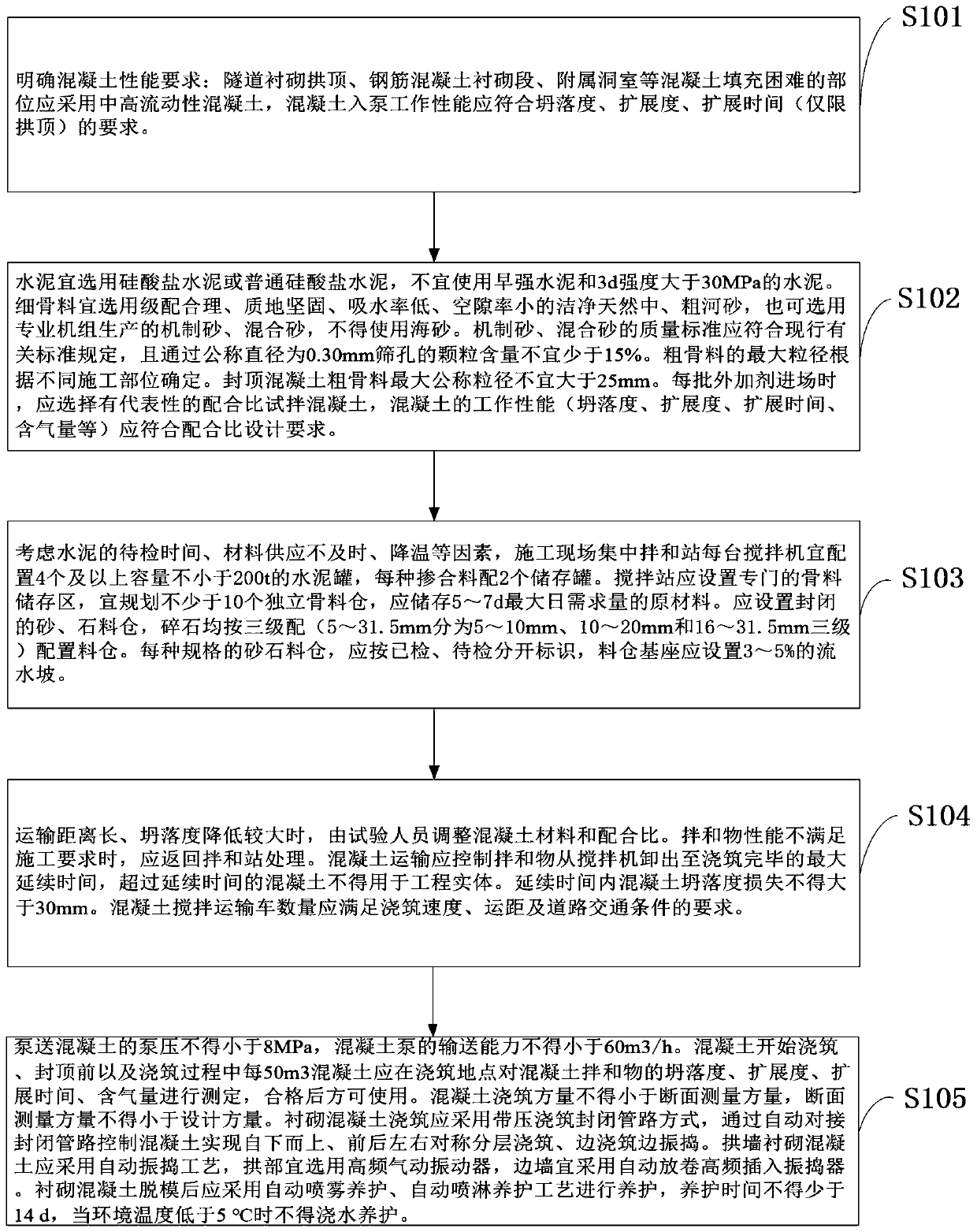

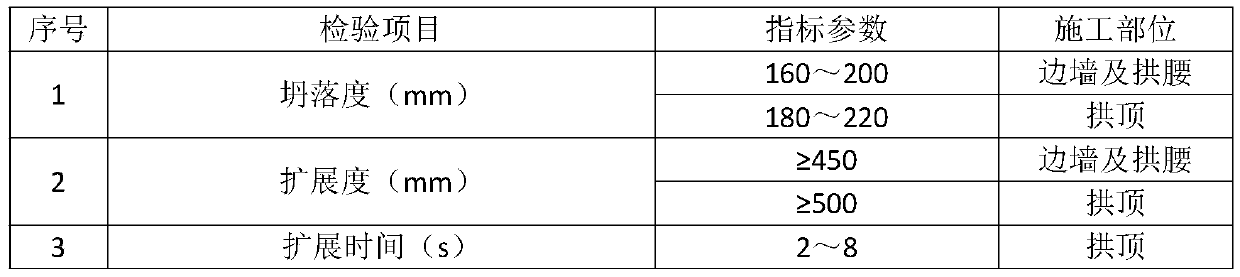

[0...

example 2

[0088] In order to verify the use effect of medium and high fluidity concrete, 27 sets of lining verification tests were performed on the lining C35 concrete of a railway tunnel project, and the statistics were counted according to the length of each set of 12m. The strength of concrete is compared with ordinary concrete, and the strength of lining is shown in Table 2.

[0089] Table 2 Comparison table of tunnel lining strength

[0090]

[0091]

[0092] Note: Three core samples are drilled for each group of linings. According to the current specification, the lowest strength value is taken as the representative value of the lining strength of this group.

[0093] Table 3 Statistical table of intermediate results of non-destructive testing of tunnel lining quality in a railway project (construction method of railway tunnel lining with medium and high fluidity concrete)

[0094]

[0095] Table 4 Statistical table of intermediate results of non-destructive testing of tun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com