Double-layer transparent conductive film and preparation method thereof

A transparent conductive film, double-layer technology, used in equipment for manufacturing conductive/semiconducting layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve problems such as short circuits and low product process yields. Achieve the effect of thin thickness, improved production yield and improved light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

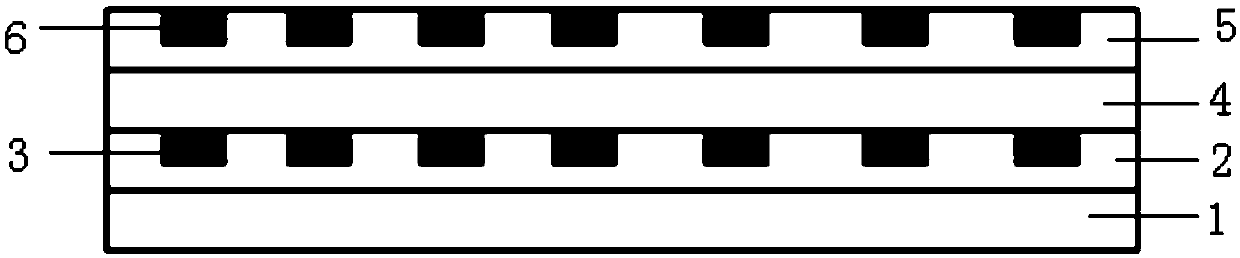

[0037] Such as figure 1 As shown, this embodiment discloses a double-layer transparent conductive film, including a transparent substrate 1, a first conductive layer 3 disposed on the transparent substrate, and a second conductive layer 6 disposed on the first conductive layer 3, so A transparent insulating support layer 4 is disposed between the first conductive layer 3 and the second conductive layer 6 , and the second conductive layer 6 is disposed on the cured transparent insulating support layer 4 .

[0038] The transparent substrate 1 is provided with a first transparent adhesive layer 2, and the first conductive layer 3 is composed of a conductive material embedded in a plurality of grid grooves on the first transparent adhesive layer 2; the transparent insulating A second transparent adhesive layer 5 is disposed on the support layer 4 , and the second conductive layer 6 is composed of conductive material embedded in a plurality of grid grooves on the second transparent...

Embodiment 2

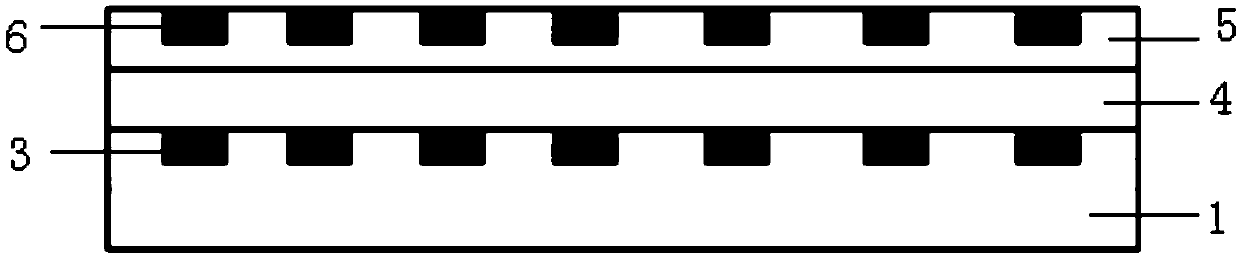

[0055] Such as figure 2 As shown, this embodiment discloses a double-layer transparent conductive film, including a transparent substrate 1, a first conductive layer 3 disposed on the transparent substrate, and a second conductive layer 6 disposed on the first conductive layer 3, so A transparent insulating support layer 4 is arranged between the first conductive layer 3 and the second conductive layer 6, and the second conductive layer 6 is arranged on the cured transparent insulating support layer 4;

[0056] The only difference from the first embodiment is that the first conductive layer of the second embodiment is formed by conductive material filled in grid grooves opened on the transparent substrate 1 .

[0057] It should be noted that, compared with the first embodiment, the first transparent adhesive layer is removed in the second embodiment, which is equivalent to a thinner thickness of the double-layer transparent conductive film. However, the effect of directly emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com