Fermented total mixed ration for ruminants and preparation method thereof

A ruminant, full-mixing technology, applied in the field of animal husbandry, can solve problems such as limited high-quality feed resources, and achieve the effect of solving limited high-quality feed resources and good fermentation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

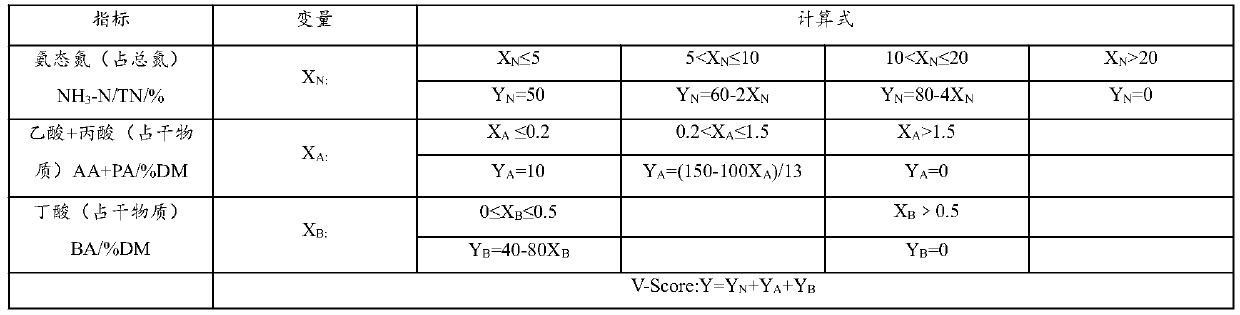

[0022] The present invention also provides a method for preparing the fermented total mixed ration for ruminants described in the above technical solution, comprising: mixing the straw, the concentrate and the aerial part of the square bean and performing anaerobic fermentation.

[0023] In the present invention, lactic acid bacteria are naturally attached to the stalks, the concentrate and the aerial part of the square bean, and the quantity of the lactic acid bacteria reaches 5 lg cfu g -1 FW can satisfy anaerobic fermentation and make anaerobic fermentation successful.

[0024] In the present invention, the time of the anaerobic fermentation is preferably 15-45 days, more preferably 35 days, and the temperature of the anaerobic fermentation is preferably 23-28°C, more preferably 25°C. In the present invention, the above-ground parts of the straw and the square bean are preferably independently processed to a length of 1-2 cm before anaerobic fermentation. The present invent...

Embodiment 1

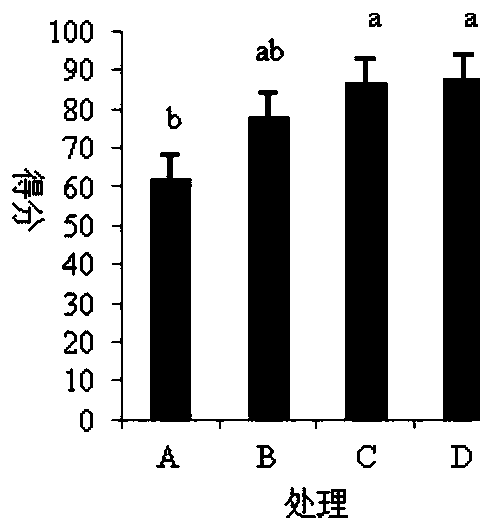

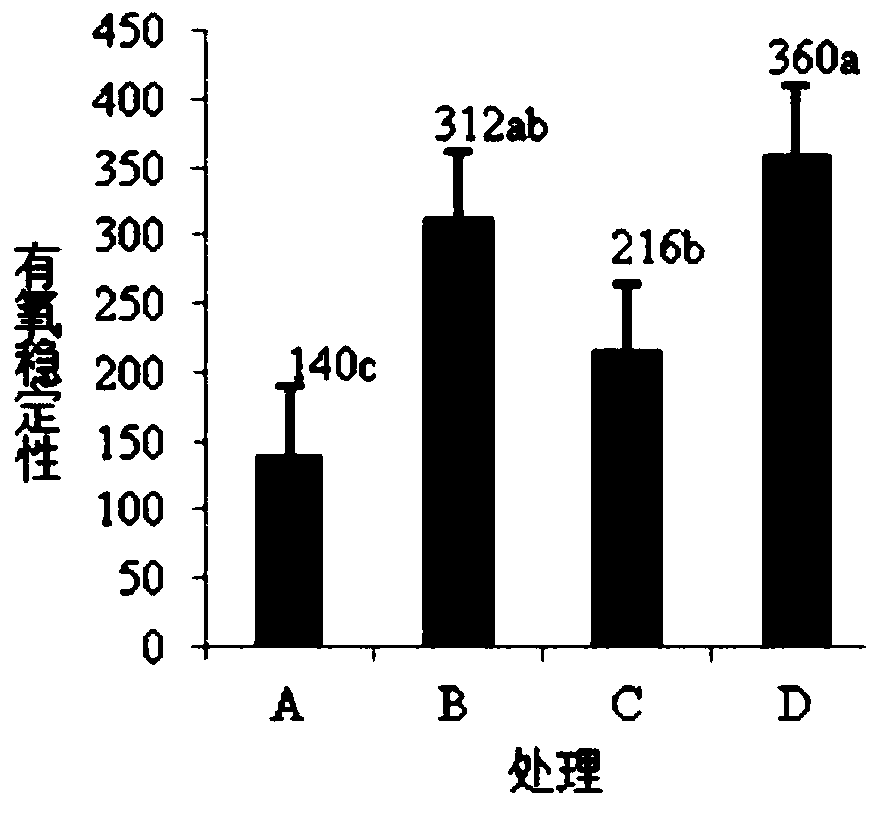

[0028] Test A: After mixing 45 parts of the above-ground part of the square bean at the pod stage, 10 parts of corn stalks and 45 parts of the concentrate, put the obtained mixture into silage bags, each bag containing 50kg, and put it under vacuum at 25°C Under anaerobic fermentation for 35 days, ruminant fermented total mixed ration (ie FTMR, Fermented total mixedration) was obtained.

[0029] Among them, the above-ground part of the square bean and the corn stalks are cut into 1-2 cm lengths with a guillotine and then mixed. The surface of the mixture naturally adheres to the lactic acid bacteria, and the number of lactic acid bacteria reaches 5 lg cfu g -1 FW.

Embodiment 2

[0031] Test B: After mixing 35 parts of the above-ground part of the square bean at the pod stage, 10 parts of corn stalks, 10 parts of rice stalks and 45 parts of concentrate, put the obtained mixture into silage bags, 50 kg in each bag, pump Anaerobic fermentation was carried out at 25° C. for 35 days after vacuum to obtain a fermented total mixed ration for ruminants (ie, FTMR).

[0032] Among them, the above-ground part of the square bean, rice straw and corn straw are cut into 1-2cm lengths with a guillotine and then mixed. The surface of the mixture naturally attaches lactic acid bacteria, and the number of lactic acid bacteria reaches 5 lg cfu g -1 FW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com