Cooking equipment and cooking method

A technology for cooking equipment and pots, which is applied to cooking utensils, heating devices, timing control ignition mechanisms, etc., can solve problems such as reduced taste and quality, discounts on dishes, and impact on user experience, and achieve the effect of avoiding poor taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

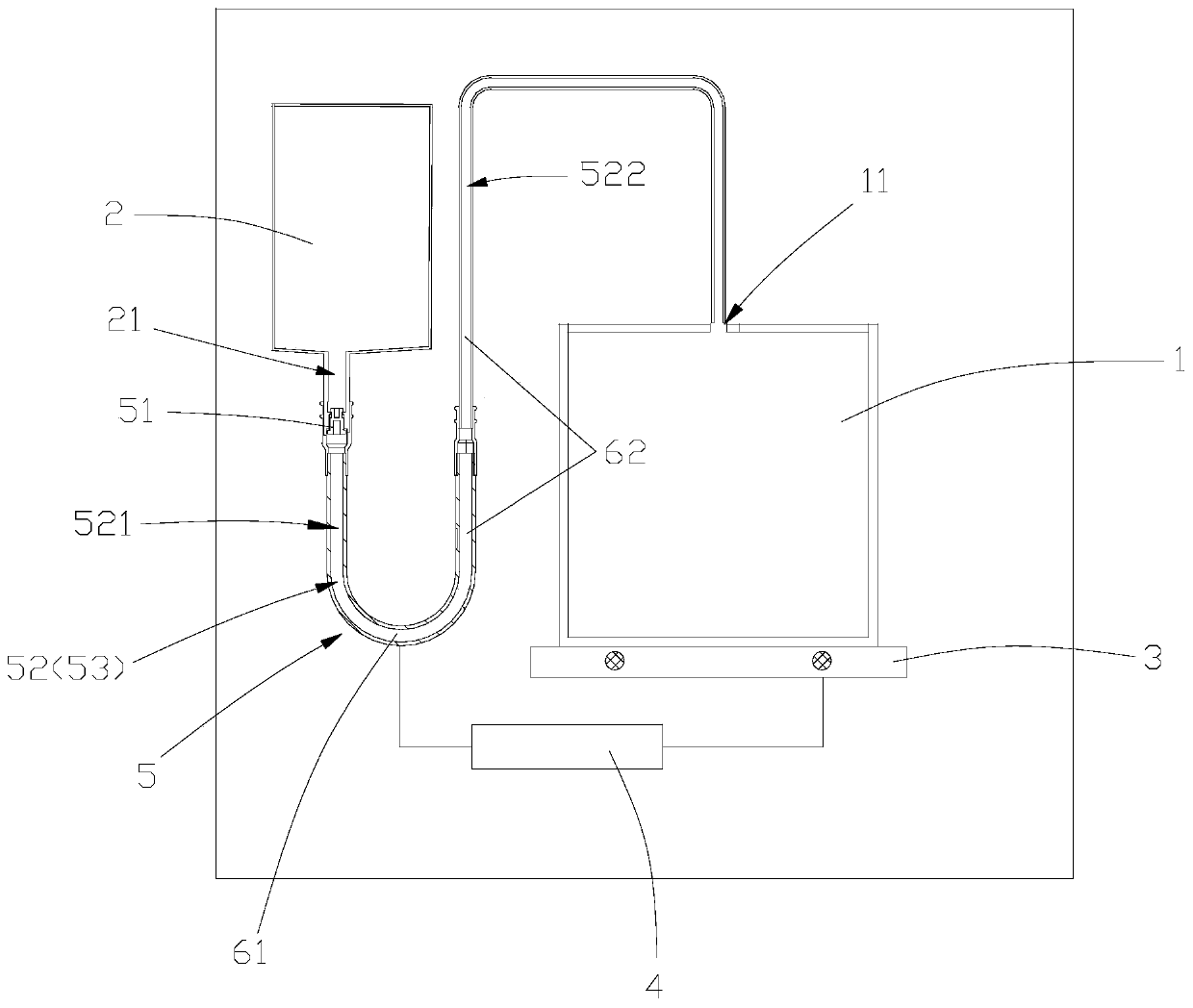

[0027] see Figure 1 to Figure 3 , this embodiment provides a cooking device, which includes a pot body 1, a water tank 2, a heating component 3, a controller 4 and a valve liquid inlet device 5, the inner cavity of the pot body 1 is used to place ingredients, and the water tank 2 is used to hold The liquid that is injected into the pot body 1 and the ingredients is mixed, and the heating component 3 is used to provide heat to the inner cavity of the pot body 1 , wherein the heating component 3 may be a heating plate arranged at the bottom of the pot body 1 .

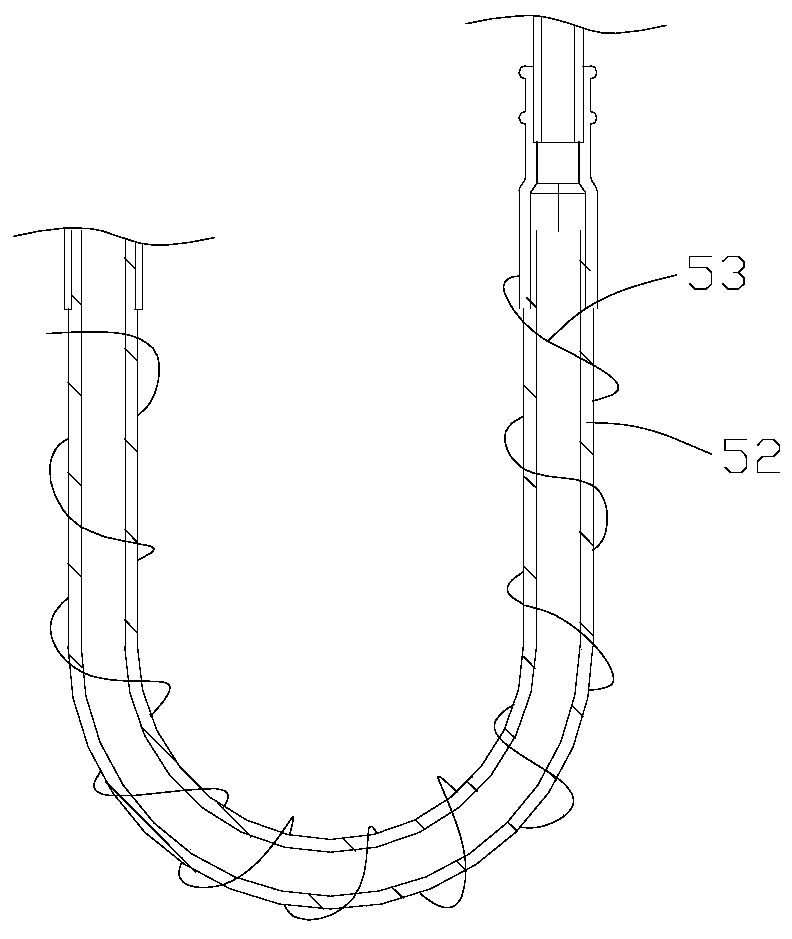

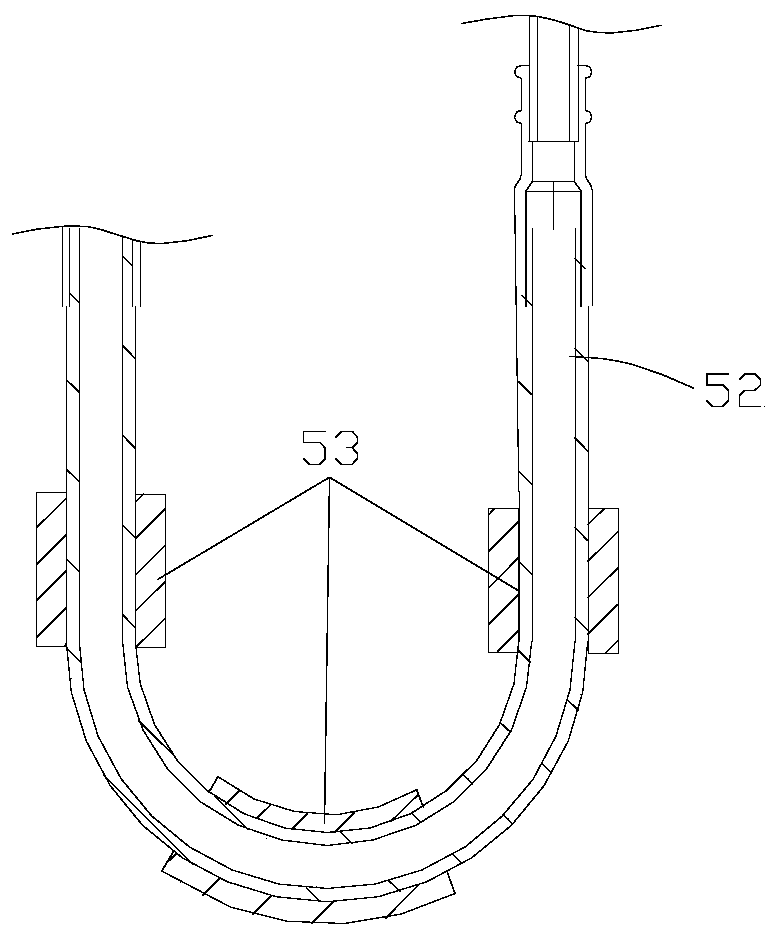

[0028] see figure 1 , the valve liquid inlet device 5 is connected to the water tank 2 and the pot body 1, which includes a one-way valve 51, a pipeline 52 and a first heating element 53, the lower end of the water tank 2 is provided with a water outlet 21, and the pot The body 1 is provided with a water inlet 11, the one-way valve 51 is connected to the water outlet 21, the pipeline 52 is connected to the one-way valv...

Embodiment 2

[0041] This embodiment provides a cooking method applied to the cooking device of Embodiment 1, which includes the following steps:

[0042] see figure 1 , the controller 4 controls the heating of the first heating element 53 and the heating assembly 3 to increase the temperature of the liquid in the pipeline 52 and preheat the inner cavity of the pot body 1 .

[0043] When the temperature of the liquid in the pipeline 52 rises to a preset temperature, the liquid is squeezed into the inner cavity of the pot body 1 to mix with the ingredients.

[0044] After the liquid is discharged from the pipeline 52, the water tank 2 continues to replenish the liquid in the pipeline 52. When the temperature of the liquid rises to the preset temperature, it will be squeezed into the inner cavity of the pot body 1, and so on until all the liquid in the water tank 2 is discharged or stops. The first heating element 53 stops heating.

[0045] The heating component 3 continues to heat the pot ...

Embodiment 3

[0048] see Figure 4 , this embodiment provides a cooking device, which includes a pot body 1, a water tank 2, a heating component 3, a controller 4 and a valve liquid inlet device 5, the inner cavity of the pot body 1 is used to place ingredients, and the water tank 2 is used to hold The liquid that is injected into the pot body 1 and the ingredients is mixed, and the heating component 3 is used to provide heat to the inner cavity of the pot body 1 , wherein the heating component 3 may be a heating plate arranged at the bottom of the pot body 1 .

[0049] see Figure 4 , the valve liquid inlet device 5 is connected to the water tank 2 and the pot body 1, which includes an electric control valve 54 and a pipeline 52, the water tank 2 is arranged on the upper side of the pot body 1, and an outlet A water inlet 21, the pot body 1 is provided with a water inlet 11, the electric control valve 54 is connected to the water outlet 21, the pipeline 52 is connected to the electric con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com