Vacuum bottle assembling system

An assembly system and vacuum bottle technology, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor costs, bacteria breeding, installation needs to go through multiple procedures and inspections, etc., to improve production efficiency, set up Reasonable and save the effect of manpower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

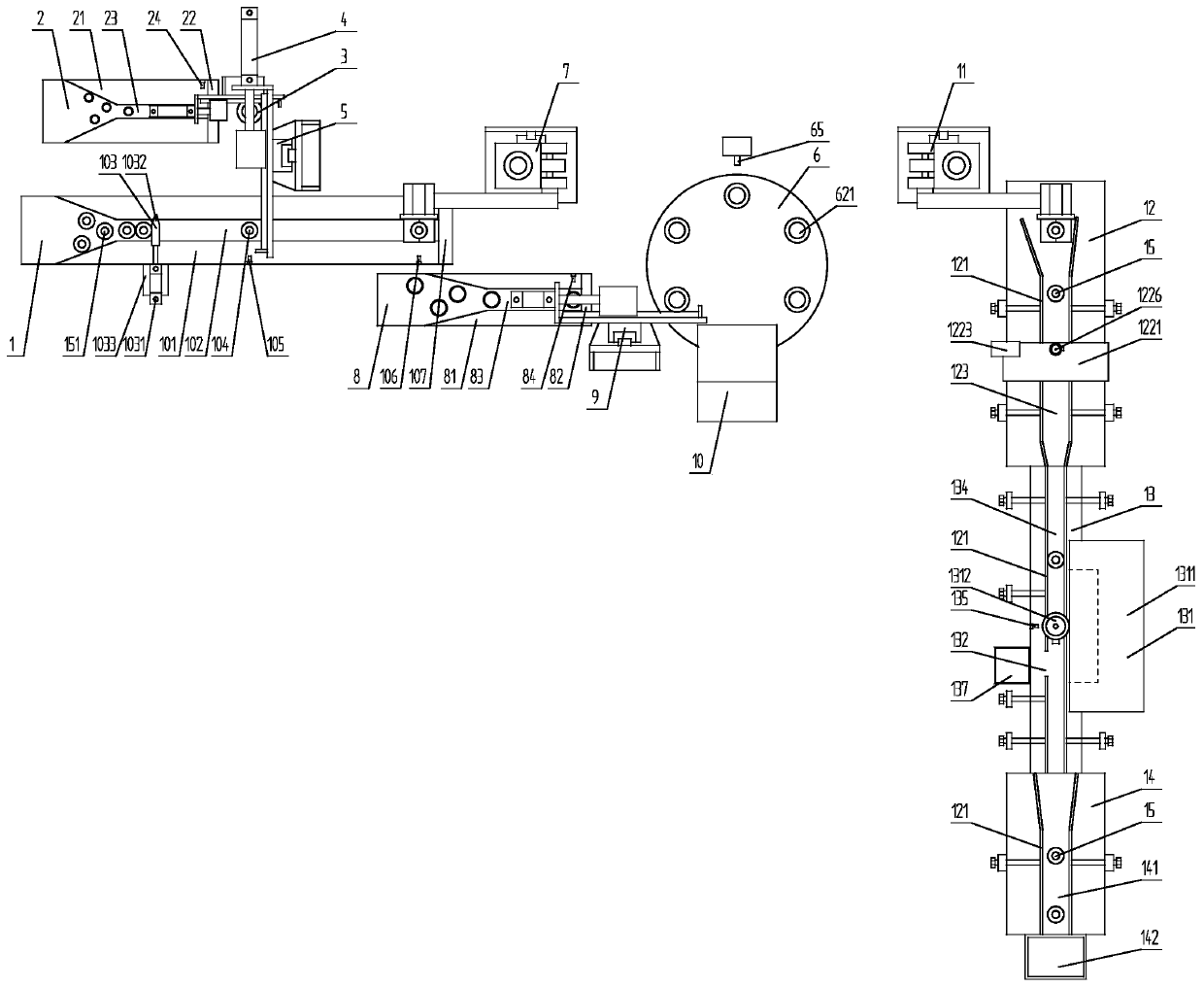

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The descriptions of "left" and "right" in the present invention are all based on figure 1 For the reference direction:

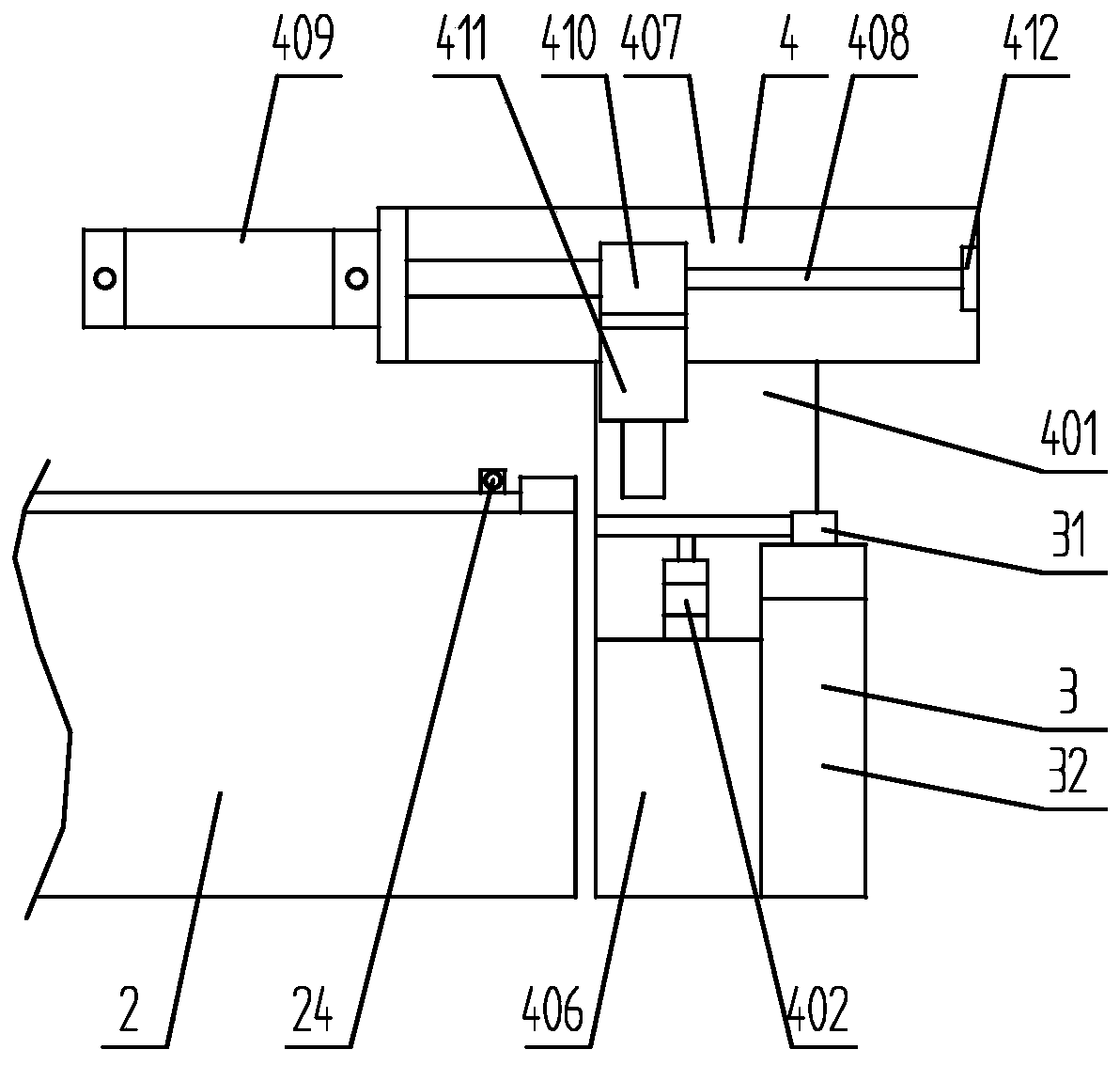

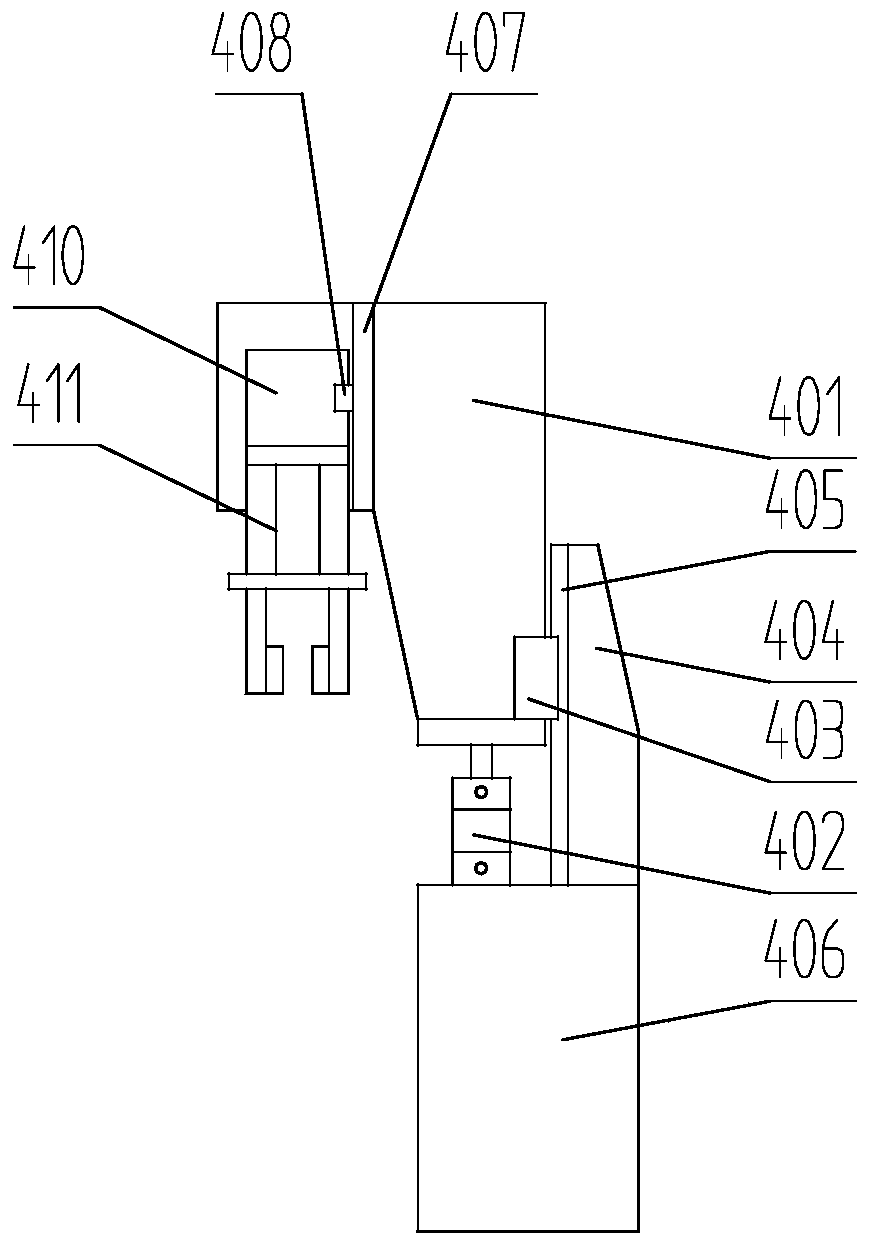

[0035] like Figure 1 to Figure 17 As shown, a vacuum bottle assembly system includes a bottle body conveyor belt 1, a piston conveyor belt 2, a piston mounting bracket 3, a rotary feeding and bottom pressing assembly 6, a bottom cover conveyor belt 8, a bottom cover feeding mechanism 9, and a semi-finished product Conveyor belt 12, airtight detection conveyor belt 13, finished product conveyor belt 14, bottle conveyor belt 1, piston conveyor belt 2 are arranged in parallel, piston conveyor belt 2 is arranged in a straight line with piston installation card seat 3, piston conveyor belt 2 is installed with piston A piston feeding mechanism 4 is arranged between the decks 3. The vacuum bottle 15 is composed of a vacuum bottle bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com