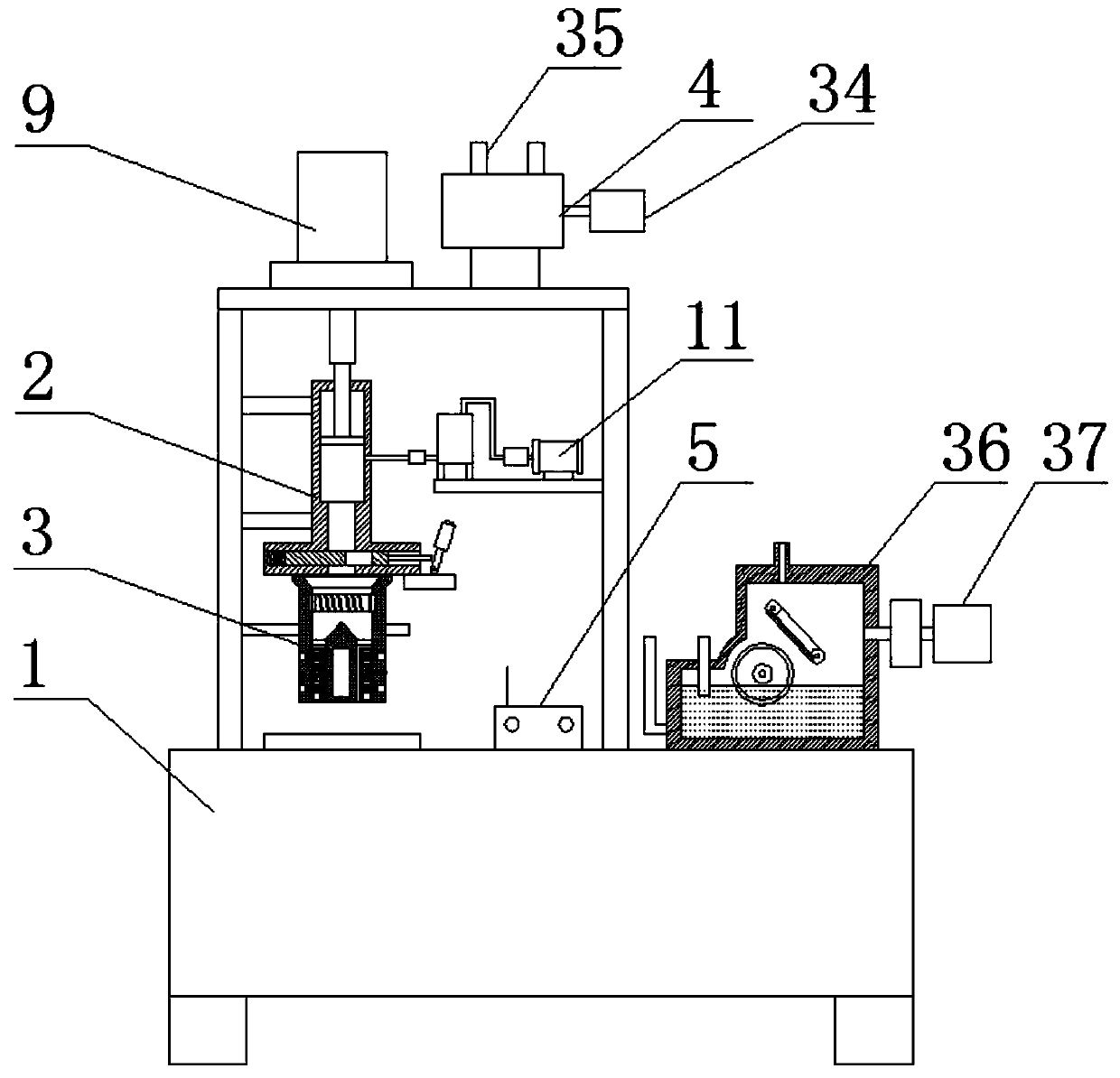

Hydraulic high-speed water-hammering punch press

A punching machine and hydraulic technology, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., can solve the problems of high noise, poor cooling effect of hydraulic oil, complicated operation, etc., to achieve effective cooling and reduce punching Hole Noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

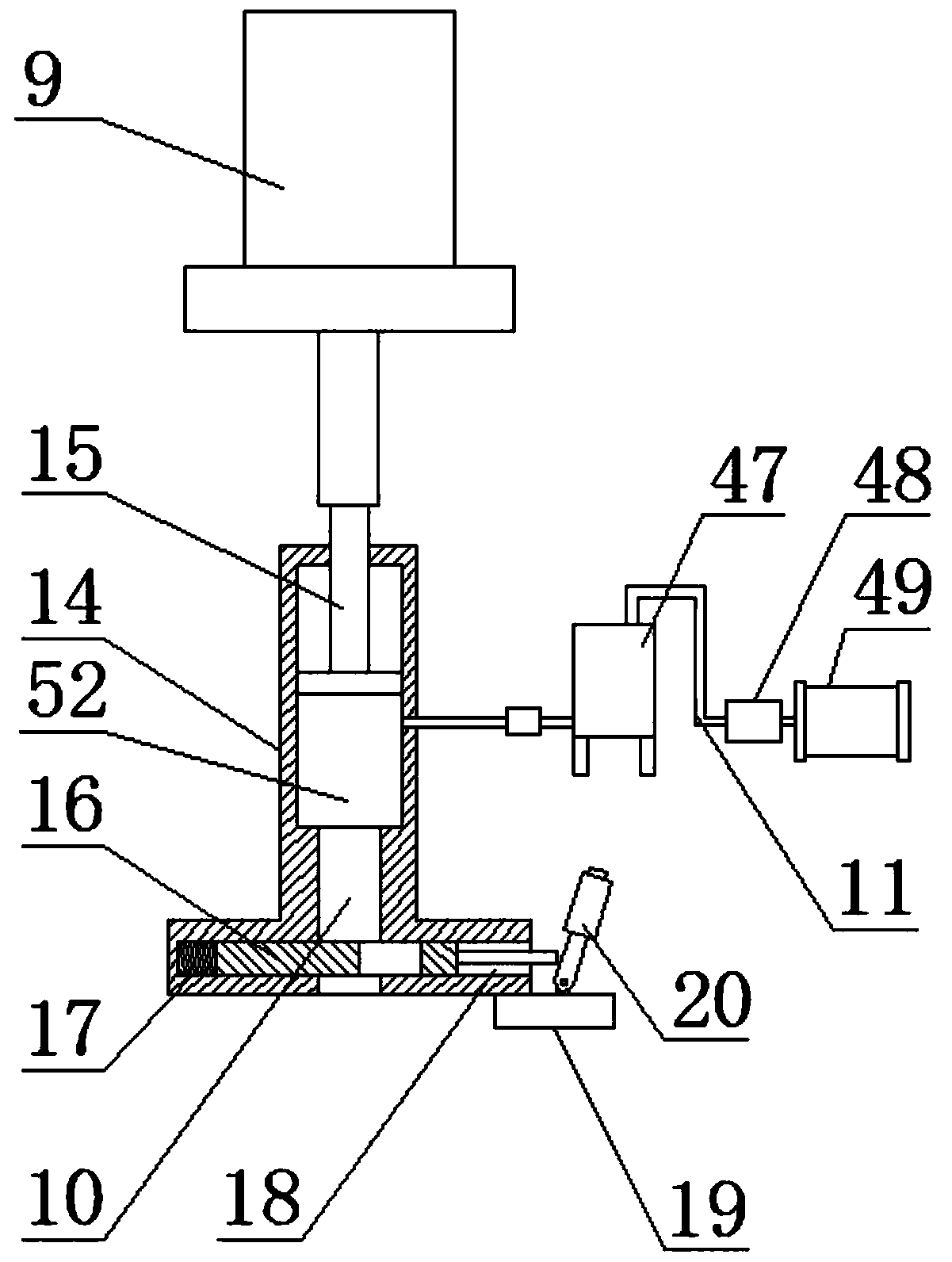

[0027]As a preferred embodiment of the present invention, the water supply system 11 includes a water tank 47, a water pump 48 and a water supply motor 49, the water pump 48 is arranged at one end of the water supply motor 49, the water tank 47 is connected to the water pump 48 through a pipeline, The bottom of the water tank 47 is provided with a check valve.

[0028] As a preferred embodiment of the present invention, the electromagnet 33 is provided with an electromagnetic winding.

[0029] As a preferred embodiment of the present invention, one end of the driving roller 43 is provided with a driving pulley 51, and one end of the driven roller 44 is provided with a driven pulley 50, and the driving pulley 51 passes through a belt and a driven pulley. The pulley 50 is connected.

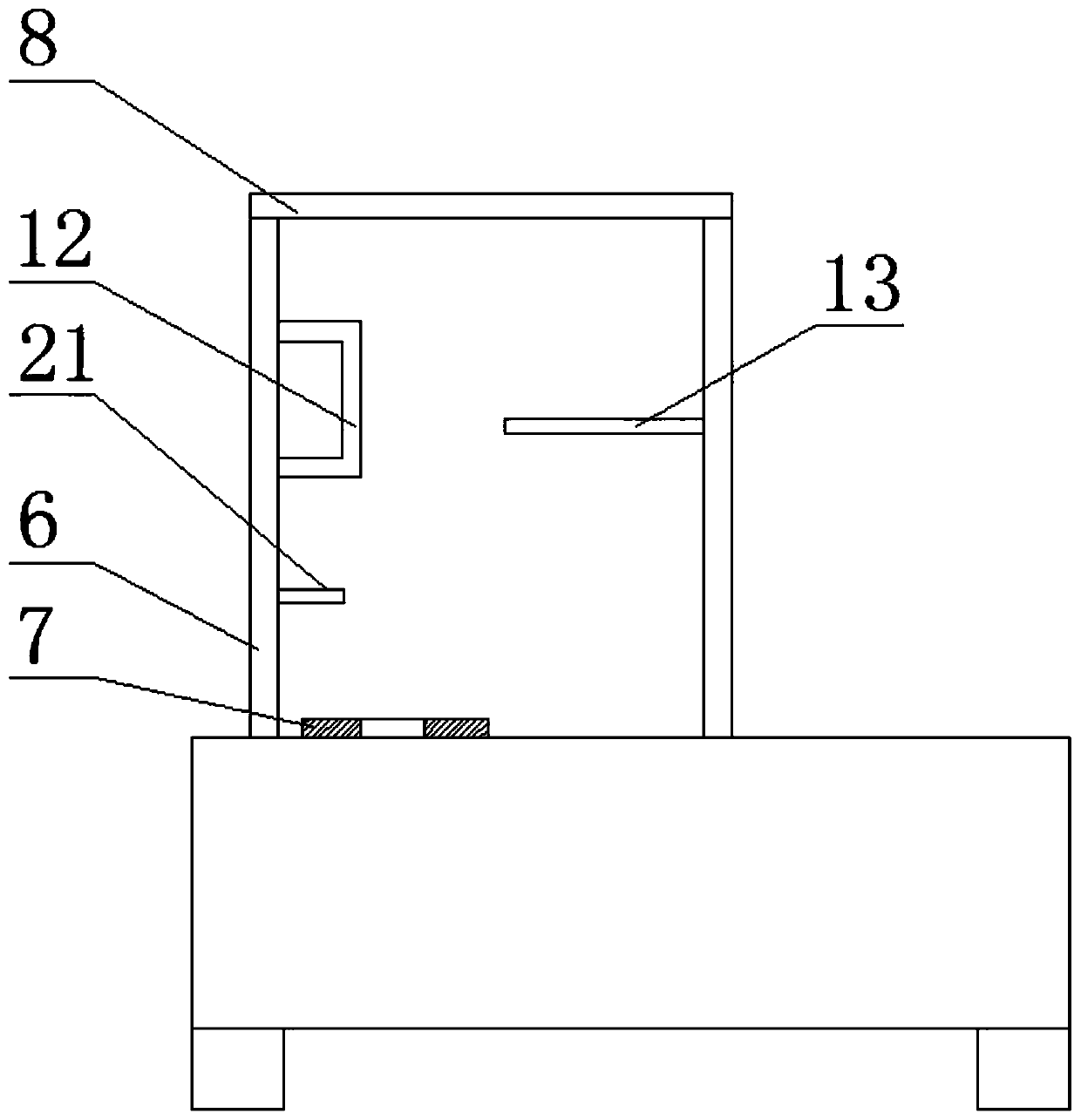

[0030] As a preferred embodiment of the present invention, the punching station 7 corresponds to the water jacket 22 .

[0031] As a preferred embodiment of the present invention, the oil tank bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com