Fuzzy pid constant speed stroke control method for large tonnage fully automatic hydraulic fine blanking machine

A fixed-speed stroke control and fuzzy controller technology, applied in the direction of adaptive control, general control system, control/adjustment system, etc. Problems such as edge force and back pressure cannot be accurately controlled in real time to achieve the effects of small overshoot, small bed vibration, and small steady-state error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

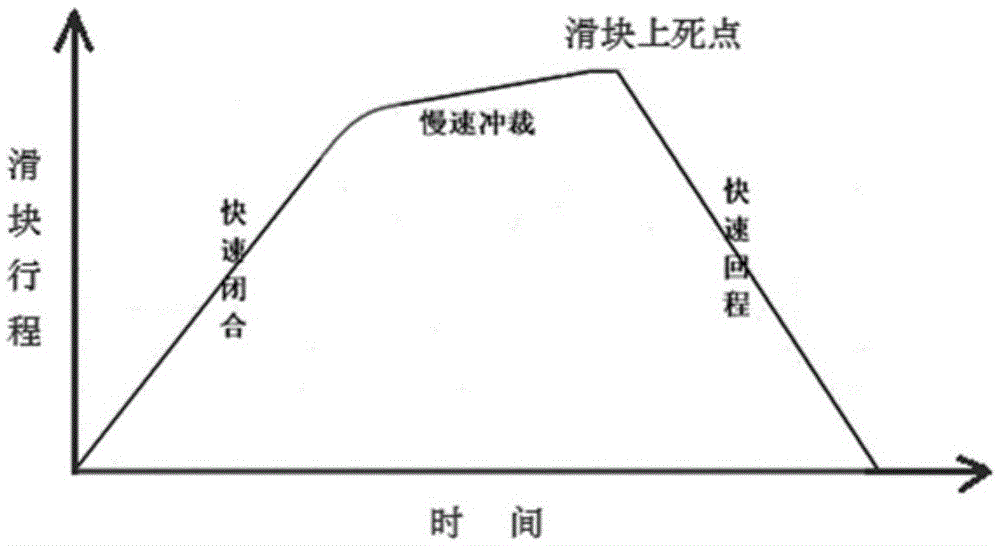

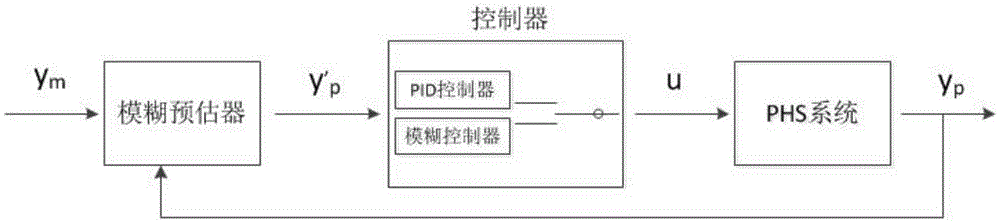

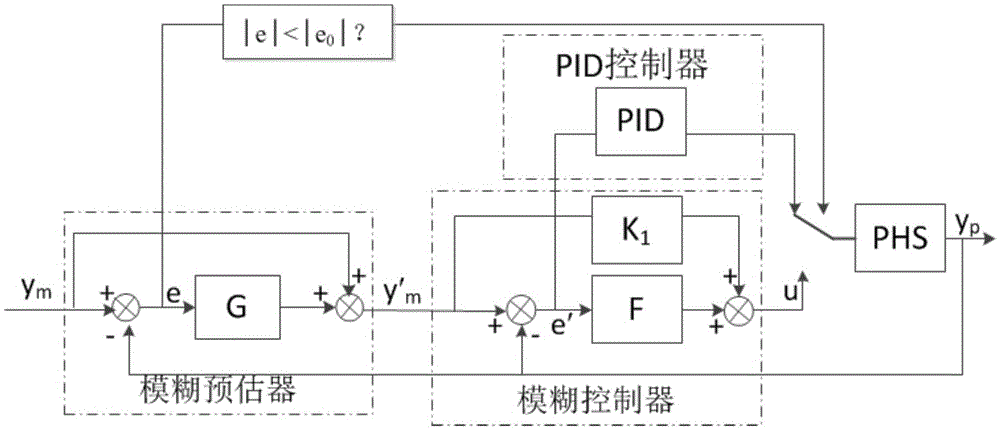

[0029] The fuzzy PID constant speed stroke control method of the large tonnage fully automatic hydraulic fine blanking machine of the present invention is as follows: Figure 2-5 shown; through the fuzzy estimator, controller and fine blanking machine ( Figure 2-6 Both are referred to as PHS or PHS system) in series to form a feedback control system to control the constant speed stroke of the fine blanking machine; the controller is composed of a PID controller and a fuzzy controller parallel to each other, the PID controller and the fuzzy controller According to the selection conditions of the controller, the main loop is formed with the fuzzy predictor and the fine blanking machine. When the controller is selected as a PID controller, the feedback control system constitutes a fuzzy predictor PID control system. When the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com